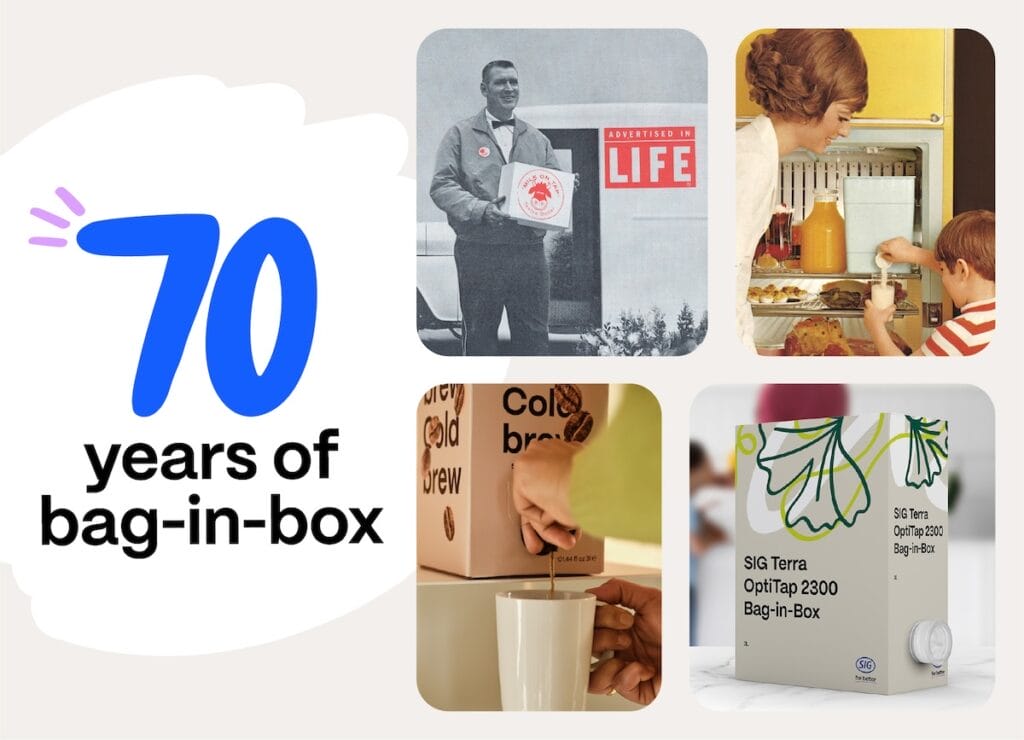

For seven decades, bag-in-box technology has enabled the efficient and safe filling of liquid products. Originally developed for industrial liquids, the system has established itself as a versatile packaging standard for food and non-food applications worldwide.

The story began in 1955 with an idea from US chemist William R. Scholle: flexible inner packaging in a protective outer box - hygienic, space-saving and easy to handle. What began as a solution for transporting industrial liquids became a globally used packaging system - in catering, retail, hospitals and production plants.

Today, the bag-in-box is celebrating its 70th anniversary - and has developed from a niche product to an established form of packaging. The system concept is at the centre of this: bags, closures, barrier films and filling technology interlock perfectly. The range of applications extends from wine, juice and dairy products to post-mix syrup, oils and water through to paints, cleaning agents and agricultural chemicals.

Milestones in packaging

In the early years of the bag-in-box, technical innovations shaped its success: as early as the 1950s, the first form-fitment system made machine filling possible. This was followed in the 1960s and 1970s by aseptic solutions and specific applications for milk and soft drinks.

With the expansion in the 1980s and 1990s, high-speed filling systems and specialised pouches for low-acid products came onto the market. In recent decades, the focus has shifted more towards sustainability aspects: recyclable barrier films, pouches without aluminium and technical solutions for almost complete emptying.

A current development step is the connection with digital dispenser systems - for simple, hygienic and controlled dispensing in food service. Intelligent connection systems enable bags to be emptied with virtually no residue, thereby increasing efficiency and cost-effectiveness.

From inventor to system provider

Today, the bag-in-box system is part of the portfolio of SIG, a leading provider of packaging solutions headquartered in Switzerland. With the acquisition of Scholle IPN in 2022, SIG fully integrated the expertise and production sites related to bag-in-box technology into the company. Today, SIG operates production plants on five continents worldwide and supplies integrated packaging solutions for a wide range of industries.

Glenn Wiechman, Vice President Global Business Line - Bag-in-Box at SIG, emphasises the transformation of recent years: „After 70 years as a pioneer in the bag-in-box sector, we are setting the course for an even more sustainable future and working towards a recyclable packaging system.“

Low weight, great effect

What makes the bag-in-box so successful is its material efficiency advantage: a large amount of product can be protected and transported with relatively little packaging material. The ratio of product to packaging is often significantly more favourable compared to rigid containers. The system is also easy to stack, saves space in logistics and reduces the carbon footprint.

Disposal costs are also comparatively low - especially for solutions that do not require aluminium and are fully recyclable. With formats ranging from a few millilitres to 1,500 litres, the system covers a wide range of applications.