Long before the PPWR came into force, coffee roaster NewCoffee was already planning to increase its use of more sustainable packaging materials and was looking for machines that could process both conventional and recyclable materials. The company favours mono-material and relies on the world's first two PMX packaging systems for coffee from Syntegon.

The German Coffee Association has announced that an impressive 463,300 tonnes of coffee were consumed in Germany in 2024. And the international market is also booming. NewCoffee GmbH roasts and packs some of the popular beans as its own coffee brand for a large international discounter. Its history goes back to the early 1960s. From its current production site in Ketsch, the company supplies the discounter's German and international branches, as well as external customers. With an annual production volume of around 35,000 tonnes, it is one of the largest coffee producers in Germany and offers the entire range of roasted coffee, including ground coffee, whole bean, pod and capsule products. Systems with a high output are therefore a must throughout the entire production process. Equally important, especially with regard to the packaging of the coffee, are flexible machines that enable different formats: This is the only way NewCoffee can easily respond to rapidly changing trends.

In addition to a number of other changes that PPWR will bring, it also regulates the recyclability of packaging: from 2030, for example, packaging with a recycled content of less than 70 per cent may no longer be placed on the market. However, NewCoffee has been pursuing ambitious sustainability goals for a long time and decided back in 2021 that all packaging machines will use both conventional films and composite materials in future. as well as recyclable monomaterials such as films made of mono-polyethylene or mono-polypropylene should process.

High performance with high flexibility

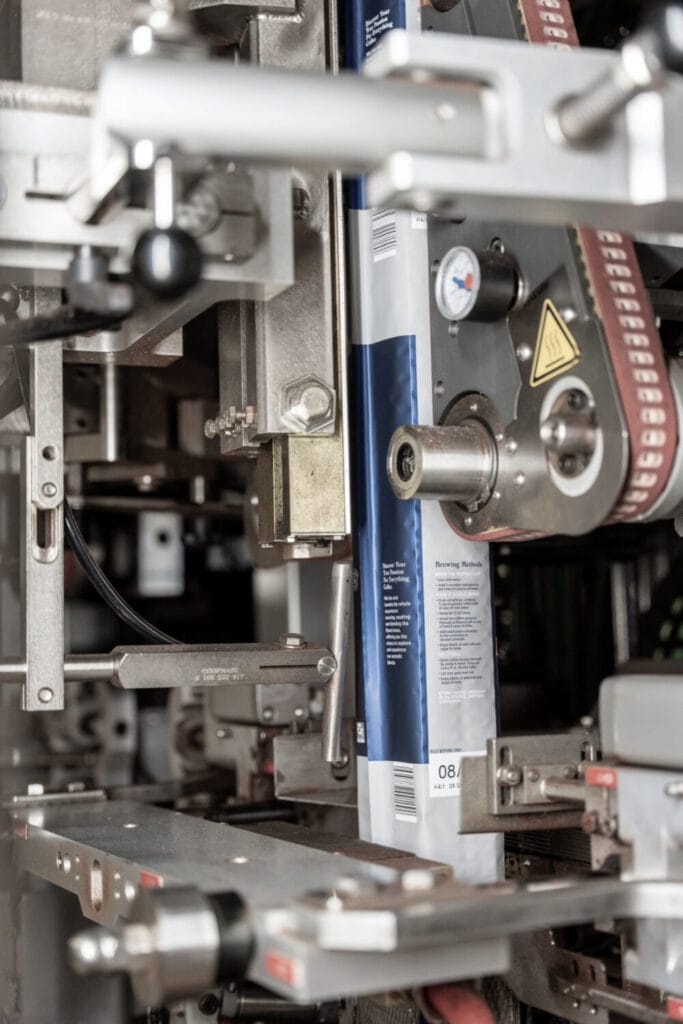

The combination of performance and flexibility convinced NewCoffee both in terms of format variety and material selection. The roasters from Ketsch already appreciated the quality of Syntegon's machines and the partnership-based cooperation with the machine manufacturer and were now interested in the PMX. The machine automatically applies degassing valves, forms stand-up pouches, fills them with coffee and then seals them. The PMX fills up to 65 bags per minute in the single-tube version and as many as 100 in the double-tube version.

The PMX also fulfils high demands in terms of flexibility and offers decisive advantages: 3D format changes on the clamping part are carried out automatically at the touch of a button. It is therefore suitable for for numerous small, medium and large packaging formats. Different bag variants and closure elements can be combined with each other. PMX produces stand-up pouches with pack weights between 200 and 1,200 grams, both with a raised and a folded-down top section. The bags can be resealed with a tin-tie, labels or adhesive strips.

„Thanks to the wide range of possible packaging variants and the fast format changeovers, coffee manufacturers can easily meet rapidly changing market requirements with the PMX without their lines having to stand still for long periods.“

Uwe Pfander, Senior Sales at Syntegon

The PMX also ensures maximum efficiency thanks to special product and flavour protection: during the packaging process, the beans fall into the bags from a very low height, which reduces the breakage rate and thus the reject rate. In addition, the beans are fumigated before and during the packaging process to minimise residual oxygen in the packaging.

Packaging material tests for the most sustainable solution

However, one of the most important decision criteria for NewCoffee was that the PMX was designed for this from the outset, Process monomaterials without loss of productivity. All stations are designed to also process recyclable packaging materials and valves. This convinced NewCoffee to be the first buyer in the world to install two PMXs: a double-tube version for ground coffee and a single-tube version for whole beans.

In addition, both companies decided in favour of Joint packaging material tests in the packaging laboratory and on the new packaging systems, to find a recyclable packaging material that optimally fits NewCoffee's needs and requirements. NewCoffee did not miss out on the unique opportunity to be directly involved in the development of a new, alternative packaging material and to help shape it according to its own requirements.

Results support production

Syntegon offers packaging material tests for customers who want to retrofit existing systems for more sustainable packaging materials or install new systems. Syntegon's experts analyse the materials in question in the company's own packaging laboratory and then subject them to a series of tests. a series of aptitude tests on the machine on site. This means that food manufacturers can be sure that sustainable packaging materials can be processed without any problems and with the planned output, without having to make time-consuming improvements later on. „For NewCoffee, we were able to integrate the laboratory tests directly into the installation phase and thus further accelerate the development process,“ emphasises Pfander.

For the packaging material tests, Syntegon and NewCoffee brought other partners on board with a number of packaging material manufacturers, who provided various mono-material films for the tests. Around 20 films made it to the shortlist and were analysed in the packaging laboratory. Among other things, the mechanical characteristics and sealing properties of the materials were analysed. Syntegon then tested five films for their processability on the machine. Based on the findings, the manufacturer of the favoured film then made final adjustments to the material and Syntegon to the machine design. Finally, NewCoffee successfully tested the film directly on the PMX in the factory. Both PMX platforms processed the mono material at full speed.

Monomaterial on a future-proof machine

„Of course, due to the joint pioneering work, there was a lot of coordination required and technical challenges to overcome. We didn't always succeed straight away - sometimes we had to fiddle around,“ explains Uwe Pfander. „But it was precisely this close and collaborative partnership that ultimately led to us always finding good solutions for all sides.“ The close proximity also contributed to this. NewCoffee was particularly impressed by the fact that Pfander's project team was not only easy to reach, but was also located close by. On site within a few hours for urgent assignments was.

For Syntegon, the direct insight into the practical use of the PMX at the plant was a valuable resource for optimally meeting the future requirements of coffee roasters that rely on more sustainable packaging materials. The collaboration is therefore far from over, even after the systems have been commissioned: Both companies are already planning the adaptation of further existing packaging machines at NewCoffee so that they also fulfil the requirements of the new EU packaging regulation.