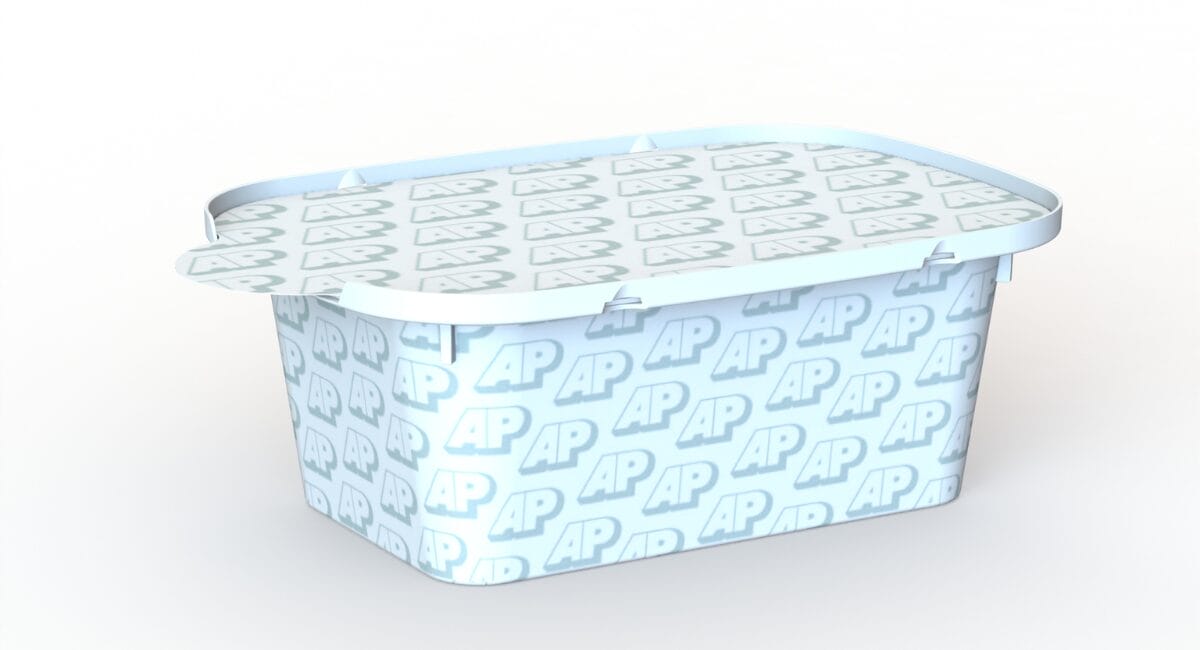

Swedish packaging manufacturer ArtaPlast now uses a fully recyclable mono-PP solution for lidding packaging from Etimex Primary Packaging, which does not require an additional aluminium blank or multi-layer composite films.

ArtaPlast AB has been purchasing sealing films from the German packaging manufacturer Etimex for over 20 years. With the mono-PP solution Vistalid a recyclable 1-seal solution for the Swedish company, which will make additional aluminium blanks or multi-layer composite films in lidding solutions for packaging obsolete in future.

The Swedish company had previously formulated the requirement to manufacture both the lids and cups of its packaging exclusively from polypropylene (PP) in order to improve recyclability. additional sealing foil made of aluminium or plastic. The aim was to streamline the packaging process by eliminating the need to apply an additional sealing film as a work step. Simple integration into existing filling systems should also be guaranteed.

In order to put the customer's requirements into practice, a film was needed that could be sealed or peeled and that could be is also perfect for in-mould labelling. The Etimex development department quickly realised that the Vistalid product solution, which is now used in white opaque with 100 or 120 mμ, would be ideal for this purpose. The film is produced at ArtaPlast additionally back-injected with polypropylene by means of injection moulding. It can therefore be used as part of the sturdy snap-on lid for dairy products, pâtés or spreads, for example.

The special feature here is that there is no need for an additional aluminium sealing foil, as the back-moulded Vistalid foil not only seals the cup, but also protects it from moisture. also seals the filled cup. This modification was able to increase the sustainability of the solution and already meets the requirements of the PPWR. The savings in purchasing and warehouse processes that this solution brings are considerable.

Another advantage of the new packaging solution is its heat resistance, which Pasteurisation in an autoclave and a hot filling system that Heating the end product in the microwave possible.

From the Scandinavian market to Central Europe

With the Vistalid mono PP solution from Etimex, ArtaPlast now has a sustainable solution that is fully recyclable without aluminium content. The mono-material PP packaging is well suited for curricular recycling and can also be produced from 30 per cent PCR material. It therefore already fulfils the expectations of the PPWR. The new packaging is also easier for the end customer to handle. This applies both to opening and closing the cup and to disposal - the 1-Seal solution can be conveniently and easily thrown into the yellow bag without having to remove an aluminium lid.

SourceEtimex : Etimex