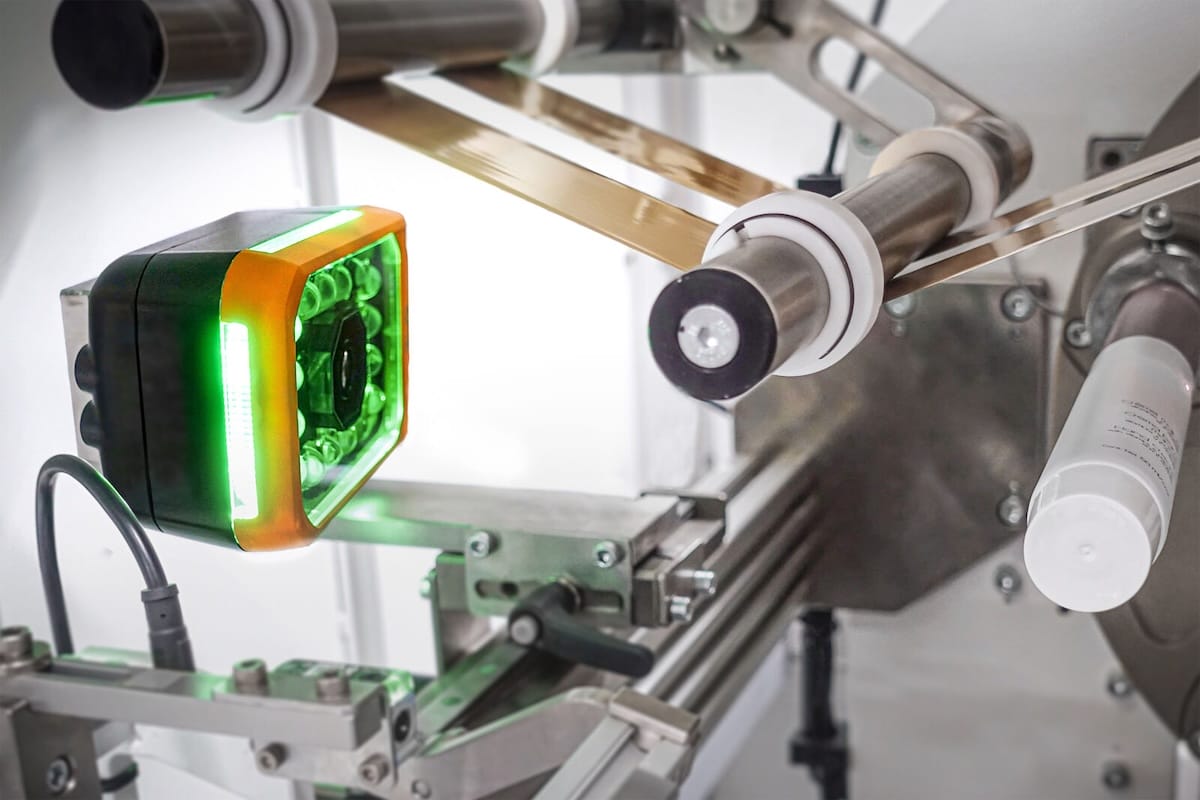

With an AI-based smart camera, B&R is bringing artificial intelligence directly into the machine control circuit. According to the company, the solution enables real-time vision, dynamic model changes and hybrid inspection processes - without additional hardware.

The new Smart Camera from B&R is intended to mark a further step towards intelligent and flexible machine automation. The camera combines artificial intelligence with classic, rule-based image processing techniques and can be seamlessly integrated into existing control systems - without an external PC or separate control units, according to the supplier.

An integrated edge AI processor handles image processing directly in the camera. According to the company, the solution is up to 15 times more efficient than comparable systems. Florian Schneeberger, Chief Technology Officer at ABB Machine Automation (B&R), said that the smart camera can be integrated directly into the control loop so that machines can be adapted during operation.

Hybrid intelligence for visual inspection tasks

The camera should be able to play to its strengths, particularly when it comes to complex tasks such as inspecting different packaging variants, recognising printing errors or sorting products. The combination of deep learning functions with conventional algorithms creates a hybrid workflow that combines speed and flexibility.

According to B&R, functions such as optical character recognition (OCR), anomaly and object recognition and semantic segmentation are supported. The camera can perform several inspection tasks simultaneously - which should reduce the need for additional hardware and minimise system complexity.

Compact integration and simplified implementation

The camera is compatible with B&R's Automation Studio development environment. According to the provider, AI models can be configured and tested in a low-code environment even without in-depth programming knowledge. Existing installations can therefore be upgraded without major effort.

According to the manufacturer, the robust optics and illumination unit are calibrated at the factory. This should improve the repeat accuracy of image capture and lead to more precise AI results - with a reduced risk of false alarms.

Potential for packaging technology

In the packaging industry - with frequently changing formats, materials and requirements - the camera could be used, for example, to detect labelling errors, check fill levels or read codes. Thanks to the direct connection to the machine control system, product quality can be ensured and downtimes minimised even at high cycle rates.