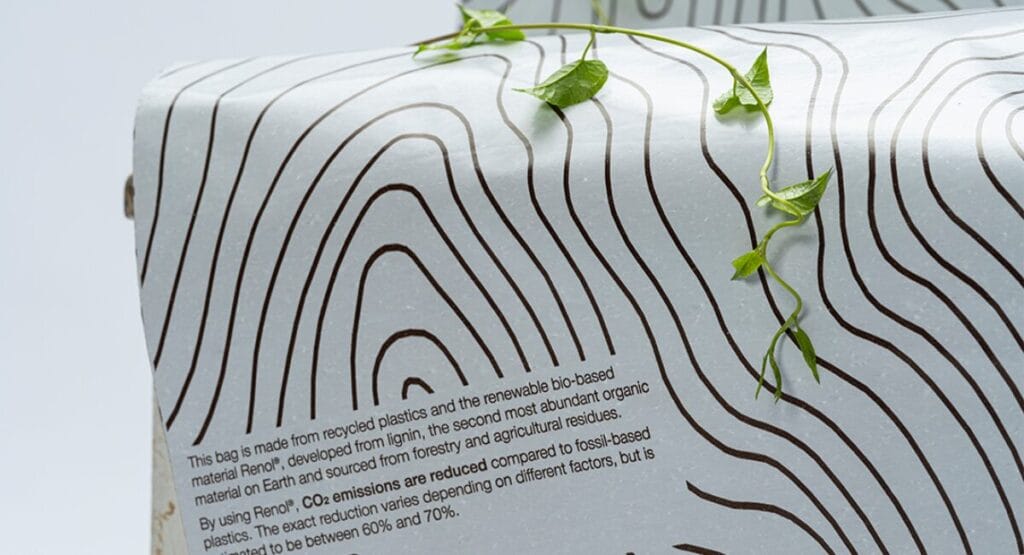

The packaging company Modepack and its partners have presented a new solution for e-commerce: Shipping bags based on lignin, a biogenic by-product from the paper industry. The development aims to increase the utilisation of renewable raw materials and reduce the use of fossil materials.

With the introduction of a new type of lignin-based mailing packaging, the Croatian packaging company Modepack wants to break new ground in the field of bio-based materials. The so-called „Lignin Mailing Bags“ consist of more than 50 per cent lignin - a plant-based polymer that is a by-product of pulp production. Together with the Estonian company Lignova Materials and the material developer Estiko Packaging Solutions, Modepack has developed a material that combines bio-based content with a recycling-friendly mono-PE structure.

Less fossil raw materials, more circularity

The aim of the innovation is clear: to reduce fossil materials in everyday packaging and utilise biogenic waste streams sensibly. Lignin is considered one of the most promising biogenic raw materials, as it is produced in large quantities as a by-product - for example in the paper and pulp industry - but has hardly been used as a high-quality material in packaging to date.

According to the companies involved, the new mailing bags are designed to be fully recyclable. The mono-material-based design - consisting of PE and lignin - is intended to maintain recyclability and at the same time improve the carbon footprint, as over 50 per cent of the contents are of non-fossil origin.

Use in online retail

The new lignin bags are intended for e-commerce in particular. Lignin packaging is intended to offer a compromise between stability, product protection and sustainability. They will initially be launched in test markets. For Modepack, the project is part of a broader sustainability strategy aimed at expanding alternative raw materials and recyclable structures in the shipping sector.

Research and scaling

According to the press release, the project was made possible by close collaboration between materials research and packaging practice. Lignova Materials contributed the expertise for utilising the biogenic raw material, while Estiko Packaging Solutions took on the further processing to create a ready-to-use packaging material. The aim is to open up further areas of application for lignin-based packaging solutions in the future and to establish the technology on a larger scale.