The German manufacturing company in Kierspe (North Rhine-Westphalia) is now equipping its injection moulding systems for the production of lip gloss bottles made of PET and PCR.

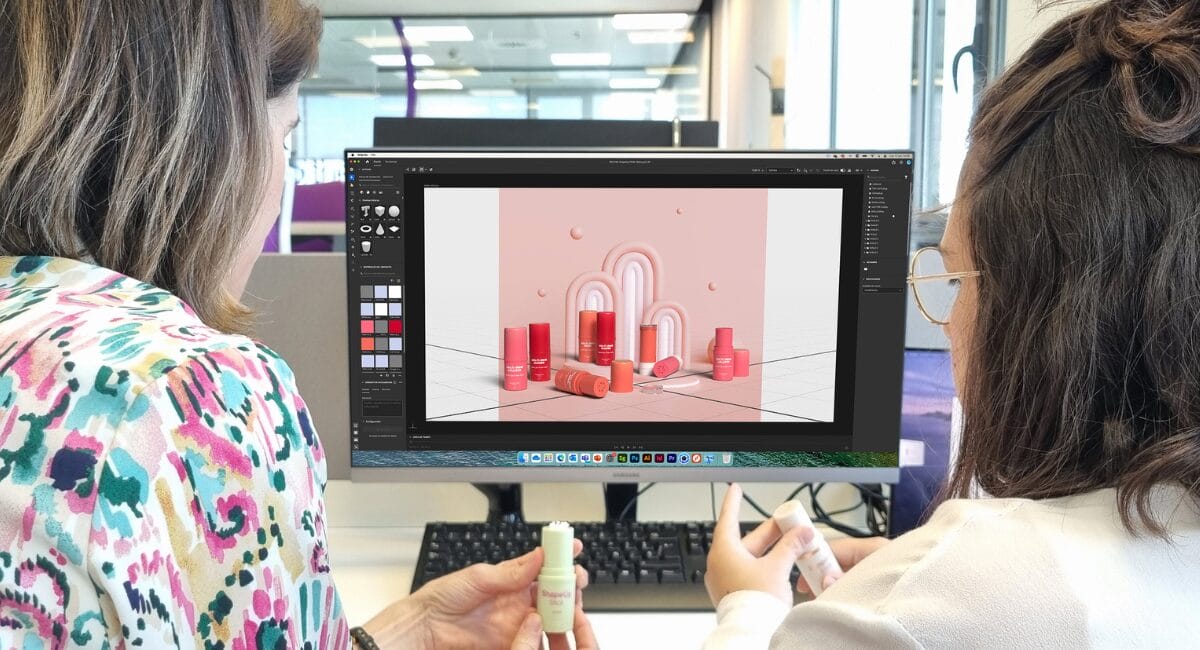

The company group has invested in new equipment for the production of lip gloss bottles made of PET at Quadpack's most important production site in Kierspe. With this measure, the company is making use of its extensive expertise in the injection moulding of thick-walled PET in order to expand its product range to include decorative cosmetics.

In addition to jars, bottles and airless dispensers for skincare products, the plant now also produces and decorates make-up packaging for a predominantly European clientele. This enables Quadpack to improve both delivery times and the carbon footprint for one of the company's key product categories.

„There is a gap in the market for dip-in packaging that is compatible with formulations with a high alkane content, particularly in the 6 ml pure PET format for lip gloss. We can now meet this demand regionally for the majority of our customers, while further expanding our position in the colour cosmetics sector.“

Pierre-Antoine Henry, Senior Director - Marketing, Innovation & Strategic Development

The new systems are intended for the production of lip gloss bottles for the dip-in packaging made entirely from recyclable PET, which is also available with a high PCR content.

Source: Quadpack