With the JetSplice process, Verpackungstechnik Jetter GmbH will be presenting a sophisticated solution for the uninterrupted splicing of roll materials at Fachpack 2025.

The technology was developed for a wide range of industries and combines efficiency, flexibility and regulatory compliance in line with the new EU packaging regulation (PPWR).

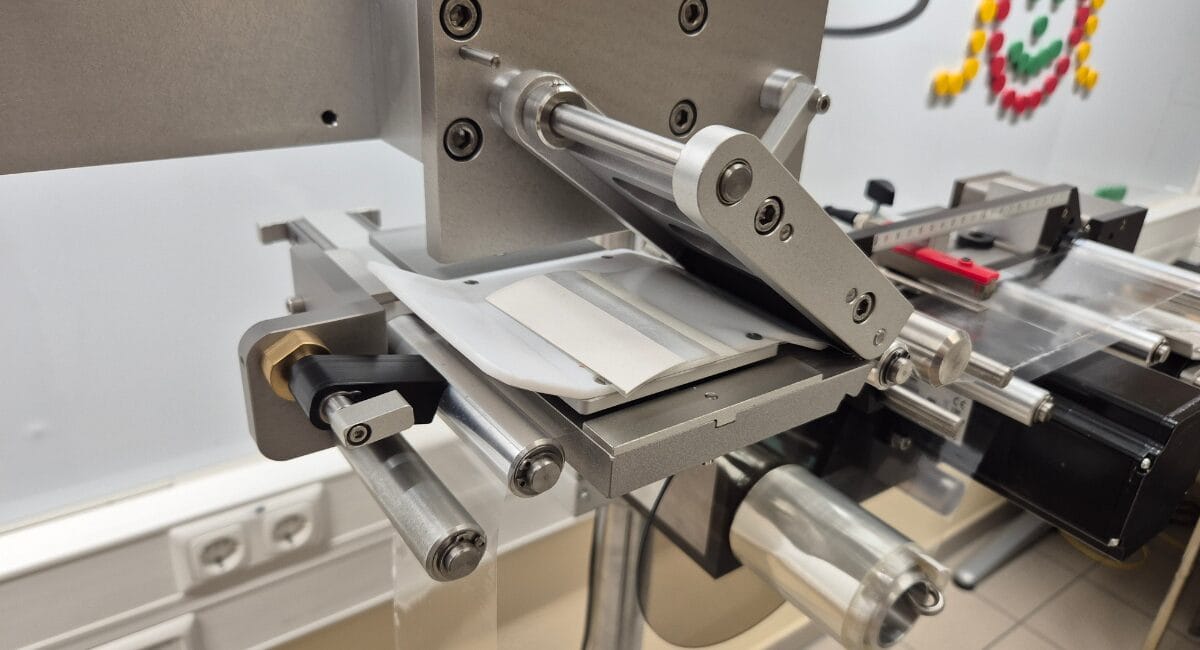

The central element is the JetSplice splicing tape, which is both for material webs made of paper, aluminium and plastic as well as for wet glue and hot melt labels is suitable. The splicing tape is used to splice the end of a web or label roll to the beginning of a new web or label roll in a special splicing head. without having to stop the ongoing packaging process.

Through the variably adjustable gap on the splice head The system automatically adapts to different thicknesses and materials of the film web rolls or (linerless) label rolls used during the packaging, labelling and marking process.

Integrable and energy-efficient

The splice head can be in existing printing systems of narrow web and converter manufacturers as well as in packaging systems or labelling machines in the packaging industry can be integrated. Depending on the requirements, a splice with an overlap of the webs or - if no web overlap is desired due to the thickness of the material webs - a butt-to-butt splice can also be realised.

The JetSplice splicing tape is already applied to the roll core by the respective manufacturer during the winding of the material/label web and attached to it. In addition to the splice head, the process requires a device for holding two material web or label rolls. Verpackungstechnik Jetter GmbH provides a simple solution that can be easily integrated into conventional machines for packaging material production, for the packaging itself or for labelling, even at a later date if required.

Material purity for the circular economy

The JetSplice process fulfils the strict requirements of the new EU packaging regulation (PPWR). The material or label webs are Depending on the material used, connected with a splicing tape identical to the material, so that no foreign matter is mixed in at any point in the overall process.

Cooperation with b+b automation and control technology

The small and robust splicing head was developed according to the design specifications of Verpackungstechnik Jetter GmbH developed by the packaging machine specialist b+b Automations- und Steuerungstechnik GmbH and is also manufactured in their factory. The various types of JetSplice splicing tape were developed by Verpackungstechnik Jetter GmbH and are produced in-house.

Source: Jetter packaging technology

Jetter Packaging Technology and b+b Automation and Control Technology at Fachpack 2025: Hall 1, Stand 454 and 556