Christ Packing Systems will be presenting a newly developed sealing unit for the FilmTeq 250 stretch-banding machine at FACHPACK 2025. According to the company, the patented top-down technology reduces the cooling requirement, saves space and extends the service life of the components.

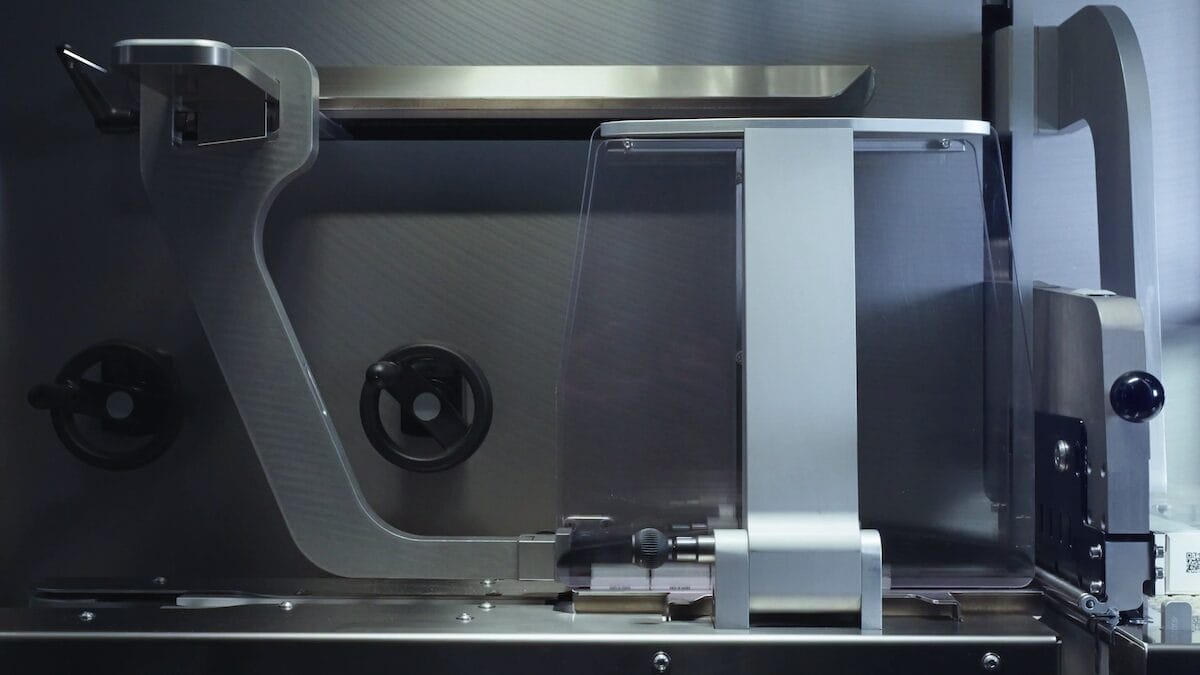

The Ottobeuren-based company has been granted a patent for a new type of sealing unit that has been developed specifically for the requirements of the pharmaceutical and medical technology sectors. Unlike conventional machines, which seal from below, the FilmTeq 250 seals from above. According to the manufacturer, this means that the sealing table remains unheated, which prevents the product from heating up and reduces the amount of cooling required.

Compact design and flexible application

The top-down process also enables a more compact machine design with a smaller footprint. The mechanically coupled movement of the sealing and clamping bars is controlled by a servo motor. According to the company, this simplifies machine control, reduces set-up time and ensures even sealing seams - a particular advantage in regulated industries.

Sustainability through longer service life

Another feature of the development is the so-called „reversible plate“ function. It allows the dual use of sealing and clamping bars. According to Christ Packing Systems, this reduces the need for spare parts, shortens downtimes and increases sustainability.

Christ Packing Systems at FACHPACK 2025: Hall 1, Stand 153