At drinktec 2025, HEUFT will be demonstrating how artificial intelligence, optimised X-ray technology and modular systems are taking quality assurance in beverage production to a new level. Highlights include AI-supported empty and full container inspection, flexible labelling and smart line analysis.

With the motto „Just look deeper“, HEUFT is focusing on comprehensive insights into the filling process at drinktec 2025. On around 1,000 square metres in Hall B4 (Stand 121/321) the company will be presenting intelligent systems for inspection, labelling and process control - many of which are equipped with the company's own deep learning technology.

Empty bottle inspection with AI support

One focus is on the further development of empty bottle inspection with the HEUFT InLine II IX system. New deep learning algorithms analyse all surfaces of the bottle - even in difficult lighting conditions and with shape deviations. The detection accuracy increases and the false rejection rate decreases. This is made possible by a combination of the HEUFT reflexx A.I. image processing developed in-house and Multi Colour Image Processing (MCIP).

In addition, a centralised deep learning model reduces the set-up effort: instead of defining separate parameters for each bottle, a single algorithm is now sufficient for a wide variety of bottle types.

Compact full product inspection at a new level

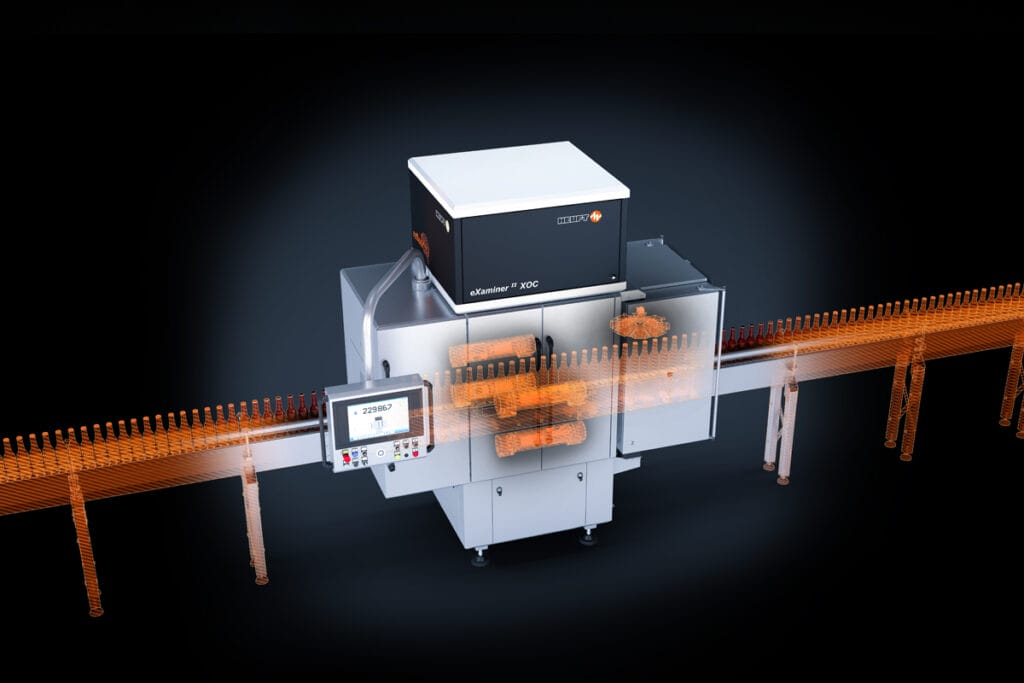

With the new HEUFT eXaminer II XOC, the company is bringing a compact version of its well-known X-ray inspector for full containers to the trade fair. The machine recognises glass-in-glass defects even in confined spaces - and without being affected by labels. A newly developed transport mechanism provides additional protection. Additional inspection modules such as closure inspection can be integrated as an option.

Its bigger sister, the further developed HEUFT eXaminer II XOS, demonstrates how small glass fragments can be detected with the highest level of reliability - for example glass beads with a diameter of just 2.5 mm. A combination of X-rays, optics and AI reduces false rejects to less than 0.2 per cent - even at high throughput rates.

Labelling: Quick changeover, flexible labelling

HEUFT will be presenting the new HEUFT TORNADO II switch for more efficiency in the labelling line. The fully modular labeller enables entire stations to be exchanged without tools via Plug & Play. Different labelling processes such as wet glue, self-adhesive or wrap-around labelling can be combined in a single work step.

Additional detection and alignment modules automatically adapt to the respective bottle format. The system is designed to minimise changeover times and maximise productivity - even with frequent type changeovers.

Label and closure inspection with a learning effect

With the HEUFT FinalView II LBL, checking labels is child's play. Thanks to intelligent image processing, a new design can be taught in in under 60 seconds. The system saves all design elements permanently and reliably recognises crooked, damaged or different types of labels during ongoing production.

Also improved: the cap inspection. The HEUFT FinalView II CAP measures the rotation angle of PET screw caps with an accuracy of up to two degrees and automatically assigns faults to the corresponding capping head - a building block for predictive maintenance.

Cans, boxes and crates at a glance

HEUFT is also presenting something new for the inspection of other types of packaging. The HEUFT canLine II now also checks empty drinks cans in areas which are difficult to access using HDRI technology and deep learning OCV. Even distorted or blurred BBD data is reliably verified.

The HEUFT PRIME checks freshly filled beverage cartons with the new pakCheck technology. Optical sensors recognise tiny deviations in the volume profile which indicate leaks. Closures, flaps, sealing films and coding are also checked.

Inspection at crate level: packs in top form

HEUFT is bringing new container inspection systems to drinktec, including the HEUFT logic II LR for checking empty containers. It recognises warped crates, foreign bottles and irregularities in the interior. During the full container inspection, other systems not only check for completeness but also logos, codes and correct filling - including a cap check and X-ray inspection of the outer packaging.

Sorting and line analysis from a single source

Another topic is the smart sorting of returnable bottles. The new HEUFT SPECTRUM II SX implements this with automatic adaptation to different bottle formats and detection modules such as a colour camera, contour inspection or residual liquid detection.

The new HEUFT CyBridge.profiler software, which centrally records the production and quality data of all connected systems, is used to analyse all processes. A new interface design and mobile end devices ensure intuitive use - including audit trail, fault monitoring and OEE evaluation.