The Wauters Group is investing in state-of-the-art finishing technologies at its sites in Île-de-France and Burgundy. New machines for hot and cold foil stamping and plastic-free metallisation expand the company's EPV-certified expertise and underline its commitment to sustainable premium packaging.

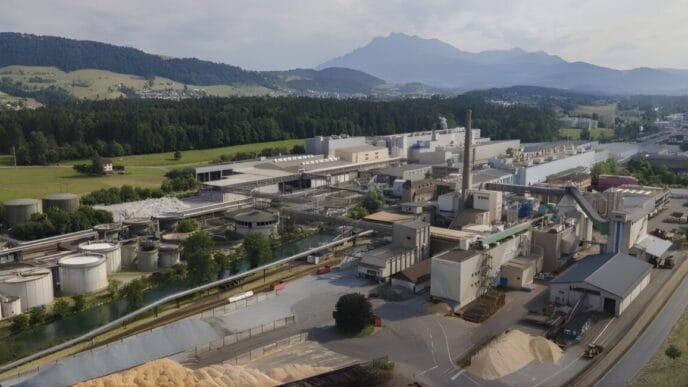

The Wauters Group is continuing its course of technological and ecological modernisation with several new acquisitions. In Île-de-France, a new dual machine that combines hot foil stamping and relief embossing in a single work step was put into operation at the beginning of October. At the same time, the B.Pack site in Burgundy received two new systems: a cold foil unit with offset printing machine and a plastic-free metallisation unit. This strengthens the company's leading role in the field of high-quality and sustainable packaging finishing.

Hot foil stamping and embossing: EPV-certified excellence

The new dual machine at the Île-de-France site enables simultaneous hot foil finishing and embossing. The combined process eliminates calibration steps, increasing precision and production speed. The result is detailed and consistent print images that meet the high demands of luxury packaging. At the same time, the system reduces energy consumption and thus the environmental impact.

This investment builds on over a hundred years of tradition at the Wauters Group: Originally started in Paris with the gilding of leather goods, the company has developed into a specialist for sophisticated packaging finishing since the 1960s. In 2022, the Wauters Group was awarded the state label „Entreprise du Patrimoine Vivant“ (EPV), which recognises outstanding French expertise, for its mastery of hot foil stamping and embossing.

New technologies for sustainable luxury packaging

The company also set new standards in the area of sustainable finishing. A new Heidelberg offset printing machine with a cold foil unit was installed at the B.Pack site in Burgundy. This technology complements hot foil stamping, requires no tools or calibration and enables a wide range of design effects while minimising energy and material consumption. The PET film rolls used are also recycled.

Another step towards sustainability is the introduction of a plastic-free metallisation unit. The metallic effect is applied before the printing process - without a plastic carrier film. Only the pure metal layer is transferred, while the film is removed and recycled. This technology will soon also be introduced at the Île-de-France site, so that both plants will be able to realise metallic effects completely without plastic in future, according to reports.

Source: Wauters Group