The cutting-die and tool manufacturer Marbach can look back on an intensive year 2025. New technological solutions for packaging processes, international industry events and progress in the area of sustainability characterised the development. For 2026, the company is clearly focussing on sustainable packaging production.

The demands on the packaging industry are changing: increasing cost pressure, greater process reliability and the transition to more sustainable production methods are determining the everyday lives of many packaging manufacturers. Against this backdrop, Marbach takes stock of the year 2025, which, according to the company, was characterised by technological advancements, international presence and an intensive exchange with customers from the packaging industry.

Industry dialogue and international trade fairs

Over the course of the year, Marbach was represented at numerous international trade events, including trade fairs and congresses in Europe and North America with a clear focus on packaging, corrugated board and die-cutting technology. The aim was to address current challenges in the packaging industry and to intensify direct dialogue with users. A particular focus was on the first Marbach Performance Summit in Heilbronn, where packaging manufacturers were given insights into production processes, tooling technologies and digital applications.

Peter Marbach, Managing Partner, explained that 2025 had shown how important close dialogue with packaging producers is in order to jointly develop solutions for more efficient and sustainable processes.

Technologies for stable packaging processes

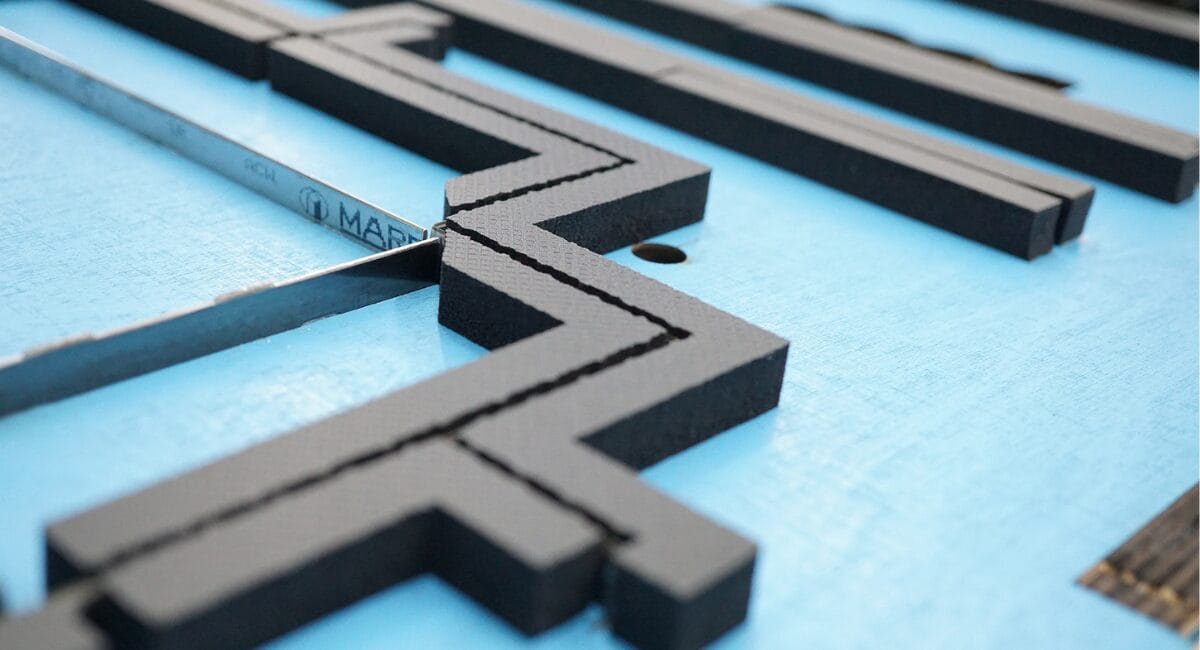

In terms of technology, the main focus in 2025 was on solutions designed to simplify day-to-day production in the packaging industry. Among other things, Marbach presented new systems for the precise use of embossing and die-cutting tools, which aim to increase process stability and reduce set-up times. The company also presented further developments for corrugated board processing, which, according to Marbach, should ensure reproducible results, especially for large-format packaging.

In addition to this, Marbach continues to focus on digital applications for recording and analysing machine and production data. These should enable packaging manufacturers to analyse their processes more transparently and identify optimisation potential.

Jan Brunner, Sales Manager of the Marbach Group, explained that the developments were aimed at making packaging processes more economical, more stable and easier to control - even under demanding production conditions.

Sustainability as part of the packaging strategy

In addition to efficiency, sustainability also played a key role. Marbach once again achieved a silver rating from EcoVadis in 2025 and joined the Science Based Targets initiative. According to the company, the aim is to support more climate-friendly and resource-saving solutions along the packaging value chain in the long term. At the same time, Marbach is involved in training and young talent projects related to sustainable business.

In parallel to focussing on packaging solutions, Marbach continued to expand its international structure: In the USA, the company took over a cutting-die manufacturer, while the site in Mexico was expanded into a manufacturing unit. As a result, Marbach is strengthening its proximity to packaging manufacturers in important markets, according to the company.

For 2026, Marbach has announced that it will continue to focus on technological development, sustainable packaging processes and intensive dialogue with the packaging industry.

Source: Marbach