With its PrePackaging Service, Faller Packaging supports pharmaceutical manufacturers throughout the entire product life cycle. The packaging specialist has now expanded its offering: the pre-packaged solutions now also include a wide range of secondary packaging services.

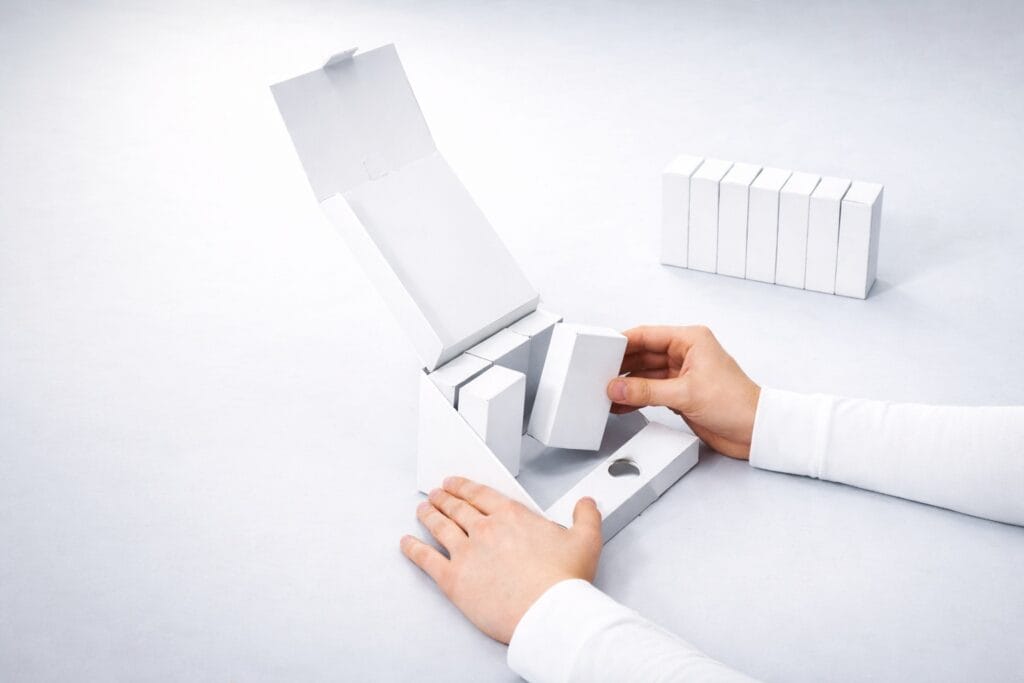

Faller Packaging supports pharmaceutical manufacturers from clinical trial phase 3 through to series production with its pre-packaging service. The specialist for folding cartons, leaflets and adhesive labels develops customised, machine-compatible carton packaging for all parenterals and various dosage forms such as vials, syringes, pens, medical devices or combination products. These can be used for both small and large quantities - without design or process changes. Depending on requirements, the packaging can be produced manually, partially or fully automatically.

Combining, bundling, straightening and more

The new services that the PrePackaging Service now offers include combining different packaging components - for example, when folding cartons are equipped with leaflets or adhesive labels. The packaging specialist can also bundle two or more leaflets, erect folding cartons and apply special labels for small and medium print runs.

The PrePackaging team also handles steps such as weighing and coding, labelling, banding and bundling, manual assembly work, display set-ups, logistics services and serialisation.

„With the extended pre-packaging service, we not only supply the pre-packaged product, but also take over key steps in secondary packaging on request. This allows pharmaceutical manufacturers to bridge bottlenecks and then simply insert their medication into the packaging.“

Michael Nemeth, Director PrePackaging at Faller Packaging.

The PrePackaging Service and the extended range of services are seamlessly integrated into the customer's value chain. Faller Packaging thus offers pharmaceutical manufacturers a reliable back-up in the event of capacity bottlenecks - when machines break down or personnel, expertise and equipment are lacking. Typical application scenarios include new product launches, clinical trials, phases with high capacity utilisation or projects to make the supply chain more sustainable by bundling packaging and logistics processes.

The range is complemented by the SeamlessPackaging Service. Together with machine manufacturer Schubert-Pharma, Faller Packaging realises packaging processes ranging from manual to fully automated, customised, scalable and future-proof.

Source: Faller Packaging