Automated Packaging Systems (APS) is presenting the latest generation of its pouch packaging systems for the first time at interpack 2017.

According to the company itself, the innovative machine series sets new standards in the semi-automatic and fully automatic pouch packaging. The new systems offer optimum ease of use combined with maximum operating safety and high packaging speed. Downtimes for changing the bag format or for maintenance are significantly minimised. Innovative bag guides enable an absolutely trouble-free packaging process.

Precise packaging of batches

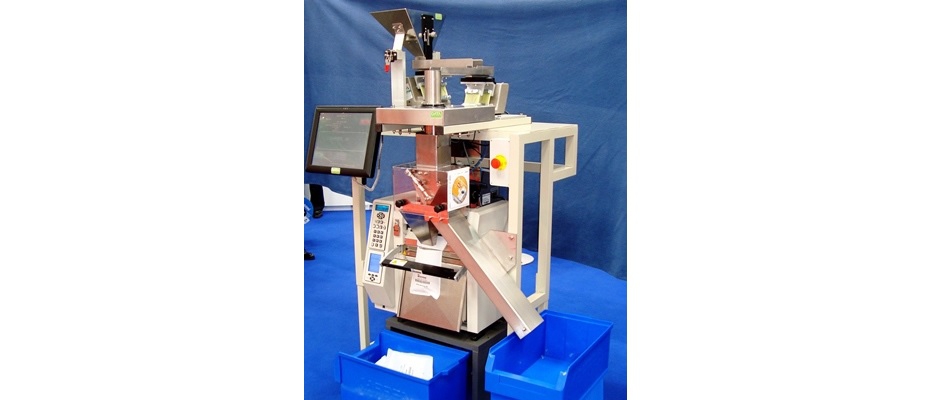

For high-precision counting and packaging, APS presents its Autobag Data-Counter. The system, developed jointly with the Israeli company DATA Technologies, enables batches to be packed with 99.9 to 100 per cent accuracy. This makes this device particularly suitable for packaging high-quality small parts.

In addition to other tried-and-tested packaging, feeding and weighing systems, APS offers automatic feeders for air cushions in the protective packaging sector. Based on the tried-and-tested AirPouch air cushion devices, the distribution systems supply individual workstations with air cushions for the protective packaging of sensitive goods as required. Also on show is the complete range of original Autobag bag from the roll with a wide range of applications such as UV protection, protection against ESD and protection against corrosion.

APS at interpack 2017: Hall 12, Stand C10