Ecocool GmbH presents the new „Smartcooler“ cooling packaging. It consists of a recycled insulating fleece, which is combined with a thin PE envelope to form a bag and sealed with an enclosed sticker. With this product, the Bremerhaven-based company is targeting shippers of foodstuffs.

The Online delivery of fresh food is booming. Examples include services such as „HelloFresh“ or „AllYouNeedFresh“. All of these senders require Refrigerated packagingwhich Temperature-sensitive foods keep them permanently cool during transport. Ecocool GmbH addresses such customers with its „Smartcooler“ solution.

Insulating solution well suited for mixed cartons

Dr Florian Siedenburg, Managing Director of Ecocool GmbH, explains in a company press release that „Smartcooler“ is particularly suitable for mixed shipping boxes with contents that need to be cooled and those that do not need to be cooled or are even sensitive to cold. For these applications, separate Insulated bag proven.

Dr Siedenburg also emphasises that the new product meets the requirements for sustainable solutions. The Smartcooler fleece bag consists of 80 per cent recycled PET and is completely recyclable.

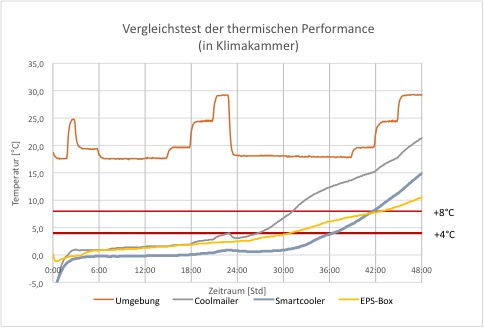

42 hours of coolness at below eight degrees

Ecocool determined the performance of the insulated bags in a test over 48 hours at temperatures between 18 and 30 degrees Celsius with three bags weighing 500 grams each. Coolpack-cooling elements. With this configuration, the Smartcooler solution kept the bag contents cool for 42 hours at temperatures below eight degrees Celsius.

The Smartcooler insulated pockets are used in the three Sizes S, M and L offered. Ecocool also has coolants in its range. Flexible cooling elements are available in five different sizes. The cool packs filled with a water-based gel have been established in the online food trade for years.

One of the users of the insulated bags is the online cooking box provider „HelloFresh“. There is a sales partnership with the start-up company.

[infotext icon]A Report on the packaging concept of „HelloFresh“ we have published in packaging journal 3/2018[/infotext].