Isra Vision has presented a new 3D sensor with a short scanning time and fast data availability. The Darmstadt-based company is also presenting innovations in its solutions for „reaching into the box“.

The 3D multi-stereo sensor „X-GAGE3D“ with its processing speed and large measuring field, is particularly suitable for use directly in the production line. However, it can also be used as a stand-alone sensor in the quality laboratory.

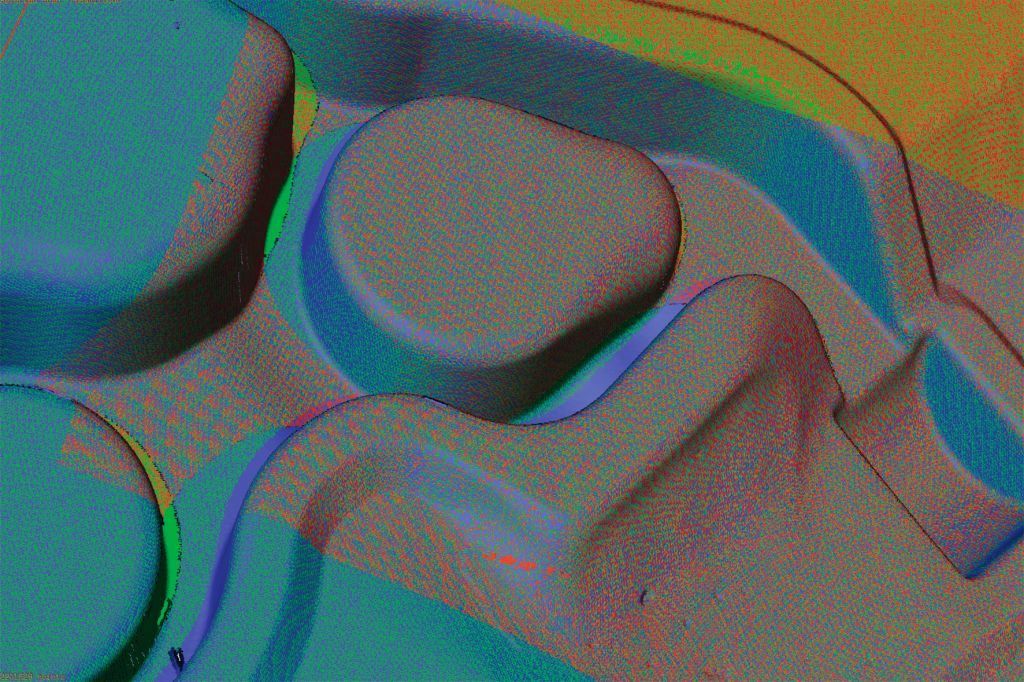

The new sensor type enables stereometric images to be taken with six different camera pairs. The advantage of this: Reflective areas are not blurred because they are correctly imaged from a different camera perspective. The sensor makes it possible to create so-called „Watertight models“ that capture objects completely and in detail. Even free-form surfaces can be checked precisely in this way.

Sensors detect all object features simultaneously

Fields of application for the sensor include additive manufacturing on the one hand and Checking objects, created on the basis of CAD data. Dimensional deviations can thus be determined quickly. The sensor records all object features simultaneously.

The sensor is operated with a Software in tile design. This can be used intuitively without prior knowledge, emphasises Isra Vision. Equipped with WLAN and the OPC/UA protocol, the sensor is also optimally prepared for networked production and Industry 4.0 applications.

„Reaching into the box“ is significantly accelerated

The sensors „IntelliPick3D-Pro“ and „PowerPick3D“ enable the fully automatic „reach into the box“. This speeds up data processing and reduces scanning times.

The „IntelliPick3D-Pro“ is suitable with its Multi-line laser illumination and optional software extensions, especially for difficult lighting conditions. Objects with dimensions of 15 to 2,000 millimetres are reliably detected. An intelligent collision avoidance system automatically plans the Optimum gripping path and enables trouble-free operation. It also recognises different container positions and types.

The new „PowerPick3D“ achieves with Quad camera technology New maximum speeds for Scanning times in the millisecond range. Using the multi-stereo method, four integrated cameras record the components to be gripped in the container. The sensor automatically creates an optimised gripping sequence and calculates the corresponding robot paths.

The „PowerPick3D“ is also available with WLAN equipped. Industrial communication is realised with the standard OPC/UA supported.