Loesch Verpackungstechnik from Altendorf is celebrating its big anniversary in 2019. The manufacturer of packaging machines and systems for chocolate, chewing gum and long-life baked goods will then have 100 years of eventful history behind it.

Today, the company is one of the innovation leaders in packaging machine construction and supplies top producers of chocolate, chewing gum and confectionery.

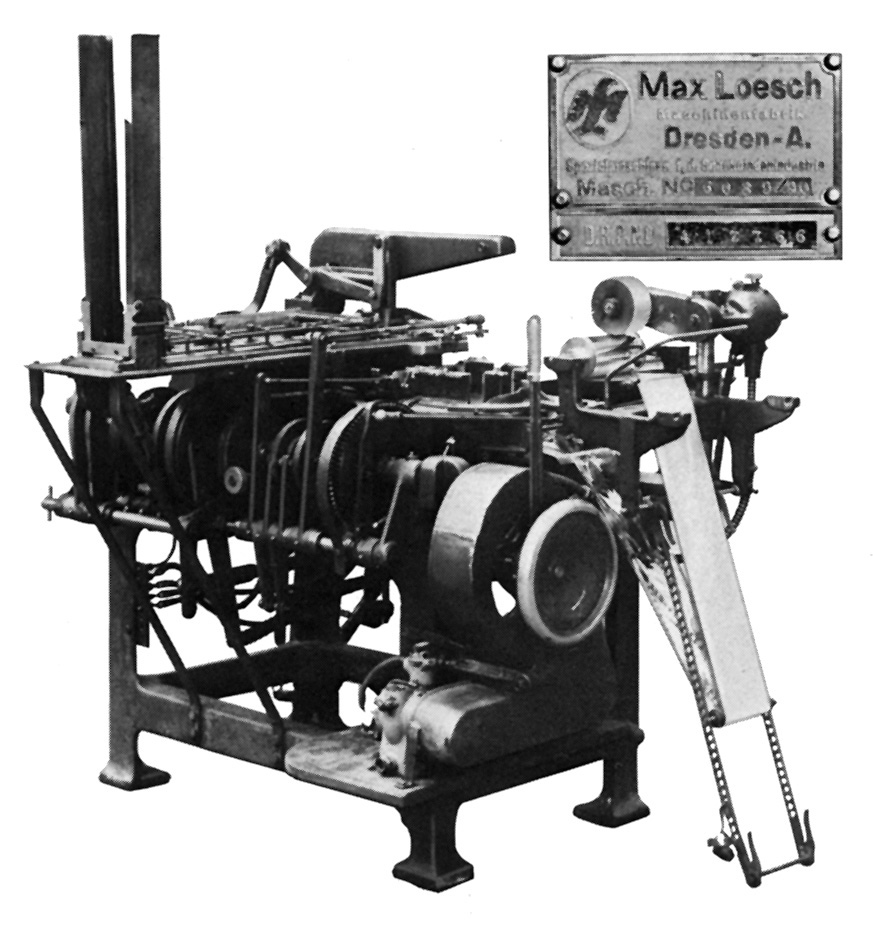

The origins of Loesch Verpackungstechnik lie shortly after the end of the First World War in 1919, when Max Loesch founded a company in Dresden for the manufacture of packaging machines and production systems. Automation had arrived, and the company founder saw potential for a company that could produce machines for the packaging of goods. Packaging of chocolate bars produced.

From 1919 until well into the Second World War, the production of Single-panel systems the core business of Loesch. One of the developments was the Fold wrapping machine LTM At the time, it was regarded as the absolute high-performance machine on the market. The machine packed 60 bars of chocolate per minute, which was a technological peak performance at the time. After a copy of the machine was refurbished by trainees, the machine is now fully functional in the foyer of the parent company Piepenbrock.

While the degree of automation of the processing machines was already relatively high at this time, the technical standard in packaging was different: Here there were Hardly any interlinked systems. Instead, the bars were fed into the packaging machines manually. The machines wrapped the chocolate in classic silver paper, the outside was wrapped in paper and then carded by hand. Servo technology or sophisticated sensor technology for detecting operating states did not yet exist at this time. The machines were electrically operated and essentially had three buttons: one for the main drive and an on/off switch. To be able to categorise the performance at that time correctly: Depending on the size of the bar and bar size, up to 200 larger bars per minute are packed on one machine today. The diligence and inventive spirit of Max Loesch and his technicians set the pace on the way to fully automatic packaging of confectionery. The company gained a good reputation in its sector and soon supplied hundreds of its Loesch packaging machines to chocolate manufacturers throughout Germany and neighbouring countries.

New start in Upper Franconia

The company continued to produce in Dresden well into the Second World War. After the end of the war, the Soviet military administration began to expropriate companies and transfer them to state ownership - including Loesch. The companies were organised in the so-called NAGEMA summarised. The abbreviation of the combine stood for Nahrungs- und Genussmittel Maschinenbau, and the group would later be under the control of the GDR's Ministry of Light Industry. Shortly after the expropriation, the former owners made their way to Forchheim in 1949 and took some of their former employees with them to Upper Franconia. There they re-founded the company and continued to concentrate on the packaging machine market. On the premises of the chocolate and praline manufacturer Piasten, which is still based in Forchheim today, a new start was made with ten employees.

LoeschPack received a small production hall and office space as rental property. In terms of operating technology, the company practically started from scratch. However, the owners and some key technicians who had followed the company to Franconia brought a lot of expertise and market knowledge with them. The close proximity to the chocolate manufacturer Piasten resulted in synergies for Loesch when testing new developments. For example, the first fully automatic system for the packaging of praline packs, LPK, was constructed.

New machine concepts

The company developed well and had around 400 employees at its peak in the 1960s. The in-house production rate was almost 100 per cent. The company also grew structurally and moved into new premises on its own property in Forchheim in 1970. LoeschPack acquired a good reputation on the German packaging machine market. In the 1960s, the company had begun to specialise in Packaging machines for chewing gum strips to deal with. New machine concepts were developed and sold with great success. Several hundred machines from the LOGAMAT series were built and were very popular with manufacturers from the growing chewing gum industry. With the machines, the then typical strip packaging as they can still be found at the supermarket checkout today.

New investors and the takeover by Piepenbrock

A Swiss investment company and an Italian manufacturer of single-sheet equipment and packaging machines were brought into the company as new shareholders in the 1960s. The descendants of Max Loesch were the third shareholders. Loesch ran into financial problems in the 1970s, as the shareholders from Switzerland and Italy refused to provide an urgently needed financial injection. For this reason, the company became insolvent in 1981.

The Upper Franconians were very lucky to have a competent consultant. Production could be maintained, and even during this time, the majority of customers remained loyal to the company. Because they did not want to lose Loesch as a good supplier, some customers even paid the full purchase price when placing the order. In 1982, the Piepenbrock Group of Companies the company. The Osnabrück-based family business was previously mainly based in the building services segment and was now pursuing a diversification strategy. A management consultant had evaluated various industry segments and identified growth markets. Packaging machine construction recorded enormous growth rates during this time.

The driving force behind the takeover was the Managing Director Hartwig Piepenbrock. Piepenbrock acquired a small group of companies during this phase: Until today LoeschPack and his Sister company Hastamatwhich is also at home in packaging machine construction, remained in the group of companies.

Move to Altendorf

Piepenbrock invested in LoeschPack: new factory buildings were built a few kilometres north of Forchheim in Altendorf, creating better conditions for production. The reason for the New building This was due to the fact that the number of employees had decreased significantly in the meantime, the production facilities were no longer state of the art and were too large. The small town of Altendorf near Bamberg was located in the so-called "Zonenrandgebiet", which was the area up to 50 kilometres from the border with the GDR. This invisible line ended 300 metres behind LoeschPack's current headquarters.

The location brought with it corresponding financial support, and the mayor of the municipality made land available in a small industrial estate. On 23 March 1984 the new company building was ready for occupancy. The company experienced a Restructuringand a joint management for all companies of Piepenbrock's industrial division was installed. The product programme was retained, but from now on Further development and growth focussed. Administrative processes that had nothing to do with mechanical engineering per se were transferred to the Group's headquarters in Osnabrück.

Provider of complete solutions

Loesch intensified its contacts in the Soviet Union, which had been experiencing a phase of economic and democratic liberalisation since the mid-1980s. When the USSR ordered 20 new systems for the production of biscuit and cocktail biscuits worth a total of 300 million Deutschmarks from the Federal Republic of Germany at the end of 1988, Loesch received the order for the associated packaging machines worth 72 million Deutschmarks.

For the first time, Loesch was no longer just a manufacturer of individual machines, but also a provider of Complete solutions. The order kept the company busy for two years. The collapse of the Eastern Bloc at the beginning of the 1990s was all the more serious. The USSR had traditionally been one of the main markets for Loesch machines. Until then, the Soviets had bought in packaging machines in certain segments from Western countries. The keyword here was "oil for machines". The collapse of the market in the Soviet Union meant a drop in turnover for Loesch in the order of 30 to 40 per cent.

Faster, bigger, further

In 1997, Hartwig Piepenbrock's son Olaf joined the company after completing his studies and took over responsibility for the industrial division. This was followed by a New strategic orientationwhich allows us to concentrate on our core business while at the same time Extension and Internationalisation of the customer base.

The plan worked: Today, Loesch has an export share of between 90 and 95 per cent. The company supplies customers who around the globe are distributed. The company is represented with its machines in Australia, Europe, Asia, North and South America. Loesch is positioned as a supplier of packaging machines to the top producers of chocolate, chewing gum and long-life baked goods.

Especially the Globalisation played into Loesch's hands. The decisive point was that the company for quality products and technology leadership and decided against cheap products. Some innovative developments have been brought to market maturity at Loesch in recent years: in 1992, the company built the then fastest chewing gum packaging machine The GW01, which can package up to 2,500 individual strips per minute, is the world's largest packaging machine.

The largest share of sales is still realised in the chocolate segment. With the LTM-DUO a two-station machine for airtight packaging of chocolate bars was developed - at that time it packed 160 packs per minute, today it has an output of 215 packs. In 2001, the new LOKEM high-performance system for long-life baked goods was brought to series maturity. At the time, Loesch installed the world's largest system for packaging long-life bakery products in the USA. It packs 9,000 cookies per minute.

On the way to the anniversary

The Loesch machines are continuously developed and optimised with regard to Flexibility, Hygiene and Output capacity optimised. As both the number of employees and the volume of business grew rapidly, the factory buildings in Altendorf were extended by a new assembly hall in 2005 and then enlarged again two years later. A new office wing was also built. In 2014, Loesch opened its New technical centrewhich is available for research and development as well as product testing.

In important markets, the company established Own sales and service companiesfor example in Russia, Ukraine, the Middle East, Asia and North America. Meanwhile, a subsidiary in Switzerland is working on the design and further development of the portfolio of flow-wrapping machines. In 2015, Loesch launched its new LRM-DUO on the market and won the German Packaging Award with it. The machine combines packaging stages previously realised in two separate machines: Cardboard packaging and film wrapping.