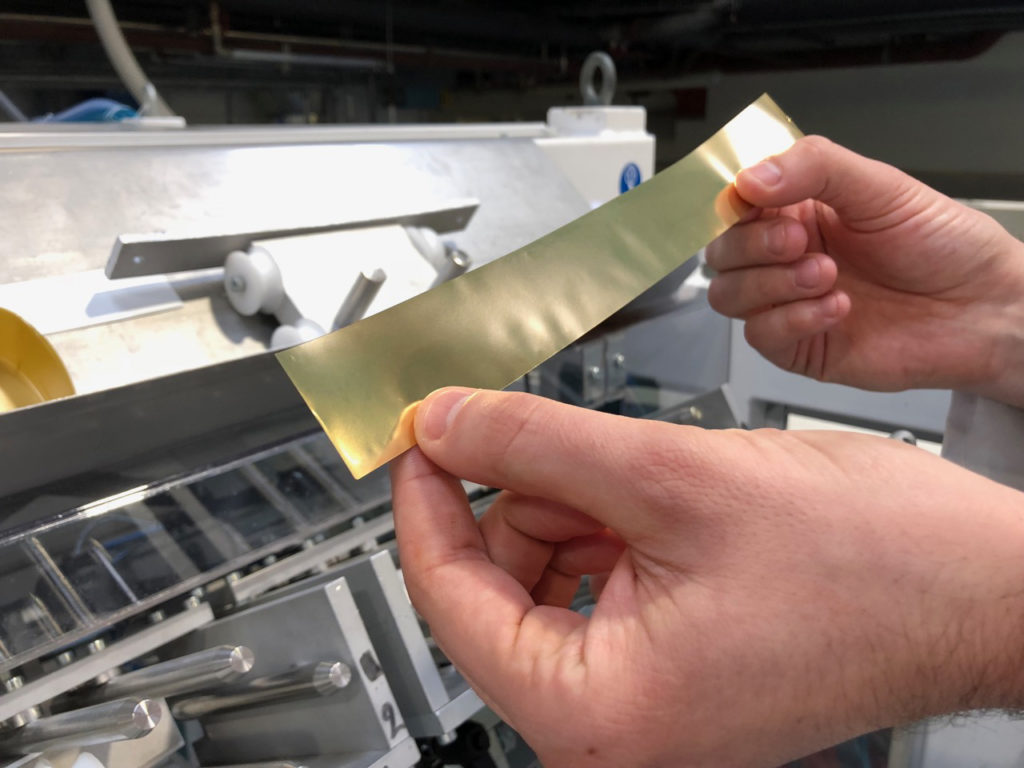

United Caps presented a brand new closure solution for the well-known Nescafé Gold coffee at the grand opening of its expanded research and development centre in Messia, France, at the end of June 2018. The golden moment is provided by an elegant metal look with a brushed surface that is wrapped around the edge of the closure. This was new technical territory for everyone involved.

It all started with a request: Nestlé wanted to create elegant packaging for its Nescafé Gold coffee to reflect the market trend for coffee products. Premium image to communicate. For its new Nescafé Gold packaging, the company was on the lookout for a elegant metal look with brushed surface. This required a material that could be 100 per cent metal and seamlessly wraps around the edge of the lid. is applied. This is a surface finish that has not yet been realised.

The United Caps specialists immediately thought of in-mould labelling (IML) technology, although they could not be sure that metallised IML was even feasible. United Caps submitted an offer, stating that considerable development efforts were still required. This resulted in a development partnership between Nestlé and United Caps in October 2015.

Successful partnership

Good companies know that they can't do everything themselves. Nestlé shares this view of United Caps and has involved its mould maker Rouxel and the robot manufacturer Pages in the project. Following the offer, United Caps has prototype was developed that illustrated the vision of the project. The proposed product was selected because it can achieve both the desired high shelf impact and is convincing in the consumer's hand.

Convince with „Look & Feel“

The experts are aware of the importance of the overall haptic and visual impression of lids and closures. The prototype has this Aspects of attention to detail and aesthetics well communicated. The next step was to build up the cross-functional United Caps team. In addition to the design department, the Practical feasibility and the Suitability for bottling plants played a major role. Even the procedure for screwing the lid onto the glass had to be taken into account.

Inspired development work

The R&D department first checked whether there were already 100 per cent metallic IML solutions on the market. There were none, and none of the available IML labels were 100 per cent metal. This was the first encounter with the impossible, as nothing like this had ever been produced before. What's more, it wasn't even certain whether it could be technically feasible at all was. Label suppliers did not consider it feasible due to the electrostatic interaction that occurred when using 100% metal in the injection mould. But United Caps was not so quick to give up.

After a few trials, Nestlé presented a second prototype that was closer to the desired appearance and could also be processed with robotic systems. However lacked the metallic effect with a brushed surface still. And again, the conclusion was reached that it was not possible to achieve a brushed metal surface during injection moulding in the mould - at least not on the label.

Technically, a demoulding bevel of one degree is required for an engraving depth of 0.01 millimetres. To achieve the desired appearance, however, 0.03 millimetres and therefore a demoulding bevel of three degrees would be required. The engraving would have to be realised inside the mould so that the brush effect would not be impaired during further processing or use. Experiments have shown that although this approach is technically feasible, it is not possible to fulfil the requirements. Limit of the possible engraving depth would come across. Nobody had managed that before either.

[infotext icon]The new closure solution for Nescafé Gold

- The lid consists of three partsThe inner part is made of PP, a PE liner as a foam seal to protect the coffee from external influences and an outer part with the in-mould label.

- The IML label consists of several layers of material. The base layer is made of PP to adhere to the lid and contains aluminium to give it a metallic appearance.

- The metal IML label is new on the market and was created especially for this lid. One Specific material mix was developed to meet Nestlé's exact specifications.

- For the production of the lids, completely New specialised machines was installed. This included three assembly lines with six all-electric high-speed injection moulding machines (SGM) for three lid sizes.

- Each week, up to 1 million lids produced[/infotext].

Extensive test programme at United Caps

The United Caps laboratory has analysed this concept in extensive tests. On the way from the production of the cap to its use by the consumer, the cap could be scratched on many occasions. This was another reason why the golden look could not be realised with an appropriate paint finish.

Fortunately, inspiring ideas can come from anywhere and they are often unexpected. At lunch in a restaurant, a developer noticed that the menu was laminated so that it wouldn't wear out so quickly. He wondered why this concept should not be applied to the project.

Another problem was that the lid could not have a seam. So is it possible to overlap the IML label to achieve a seamless look on the metal label?

Making the impossible possible

After months of persistent research, United Caps finally began production of a pilot mould at its factory in Messia. Normally, a standard pilot mould has only one cavity. This particular mould, however, had four. It was also produced in three different dimensions for the three glass sizes of coffee: 50, 100 and 200 grams. The four cavities shortened the time to market launch, as now four different concepts tested simultaneously could be analysed. The focus was on the different engraving depths, their feasibility in the IML process, the reproducibility of the process and other project parameters. This lid would be the first product of its kind on the market with an IML label on the side.

It was now July 2017, just 12 months after the project was launched, and the first prototypes of the lid for the 100-gram jar were already finished. The result was stunning. The 100 gram lid weighed 17 per cent less than previous Nescafé lids. The production tests could begin.

A golden moment

Once production was up and running, United Caps encountered a new problem: the line for the 100-gram jar was producing a Too few units per day. When the production process was checked, it turned out that a small part on the machine was slowing down throughput. Once this problem had been resolved, production was able to resume within just one hour. increased by 30,000 parts per day become. That was a truly golden moment for the team. It made it possible to achieve the target of 50 million parts per year.

[infotext]These lids for Nescafé are one of the most complex customised projects United Caps has ever undertaken. Last but not least, it created a real golden moment for everyone involved. After all, there were so many uncertainties to take into account. United Caps overcame these, thanks in large part to the Relate, Perform, Sustain„ concept“ that United Caps uses for its product development. They are the key to making the impossible possible and achieving this special golden moment.