The history of Kautex dates back to 1935. Company founder Reinhold Hagen had no idea that he would build a company of international renown in the following years - both in terms of the production of hollow plastic bodies and the necessary mechanical engineering.

Due to the early death of his father Reinold Hagen was forced to abandon his young engineering career at Robert Bosch in Feuerbach near Stuttgart at the age of 22. He returned to his hometown of Siegburg, set up his own metal and galvanising business in 1935 and, as the eldest of seven siblings, provided for the family's economic livelihood.

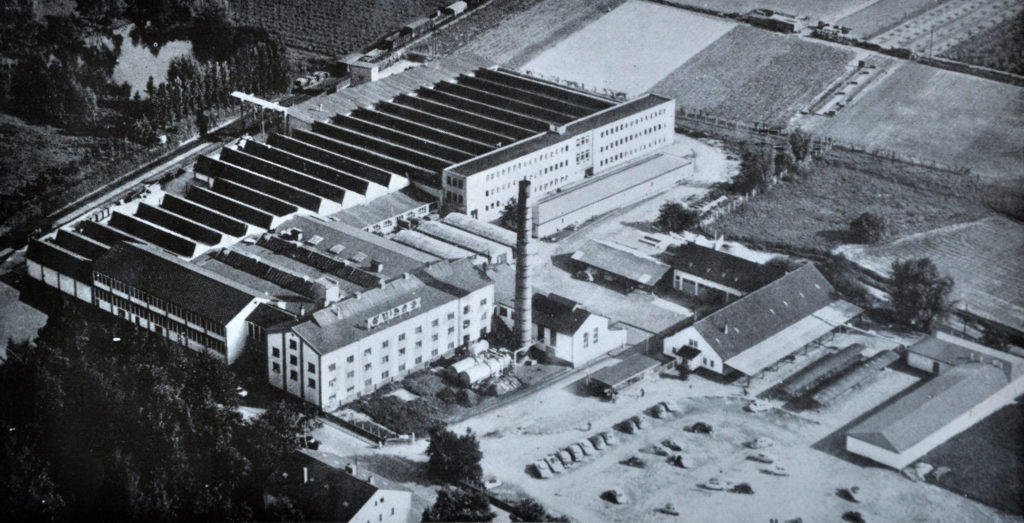

In 1945, he had to rebuild the company near Bonn. The war had destroyed a large part of the company. However, this also offered the opportunity to create something new and look to the future.

The birth of Kautex

Because a replacement for the required raw materials had to be found during the war years, Reinold Hagen initially entered the market with the Processing the thermoplastic polyvinyl chloride new process engineering territory. The end of rubber as a material seemed imminent. Reinold Hagen took this as an opportunity to rename the electroplating workshops with the new start in 1945: On a whim, the name „Kautex“ was created in the sense of „Rubber Ex“ The company's development was characterised by a departure from rubber in industry and a move towards new materials, without Hagen himself ever having processed rubber.

In 1949, his brother Theo developed a process for Inflating PVC shrink tubing. Reinold Hagen continued to experiment and finally found a method of inflating the thermoplastic in such a way that it retained its shape. Thanks to the stabilisation of the raw material situation after the currency reform, blowable polyethylene was available on an industrial scale for the first time a short time later. In the same year, the ten-litre balloon blown on a Kautex machine created the The world's first seamlessly manufactured large plastic container.

Global expansion

With the V8 blow moulding machine The first standard system in 1954 for the production of hollow bodies with a capacity of up to five litres. Its moulding principle remained valid until the 1980s. In the following years, Kautex developed into a globally operating company. In 1960, the first Kautex subsidiary was established in the USA. The export of the first machines to the USA laid the foundations for international expansion. The path led via the growth market of the USA to the establishment of the company's own additional machine production in China.

Mechanical engineering plus service

The company no longer produced exclusively for its own needs, but supplied the plastics processing industry worldwide. This primarily included extrusion blow moulding machines, but also screen printing machines for printing many hollow bodies as well as machines for processing and preparing plastics. The sales of Plastic bottles was mainly active in the packaging industry at the time and addressed manufacturers in the chemical, chemical-technical, cosmetics and pharmaceutical industries.

A global economic upturn was reflected in the increasing diversity of the consumer world. At the beginning of the 1960s, technical parts manufactured using the blow moulding process were already part of the Kautex programme: For the automotive industry, for example, Kautex manufactured complicated ducts for hot and cold air supply, bellows and brake fluid reservoirs. By the mid-1970s, the company had developed its customer service and attracted attention with the world's first series-produced plastic petrol tank (1973) and superlatives such as the 5,000-litre heating oil tank (1974).

The Krupp years

In 1977, the company was split up. The mechanical engineering division was sold by Kautex-Werke to the Krupp Group, giving it the chance to develop independently. Today, the plastics processing part of Kautex-Werke operates under the name Kautex Textron.

Under the name Krupp-Kautex, the mechanical engineering company was part of the globally active Krupp Group for around a quarter of a century. Under Krupp, Kautex Maschinenbau developed into a customer-orientated company offering a wide range of products for Different areas of application for blow moulding delivered. From then on, the company increasingly focussed on the automotive industry. After the plastic petrol tank had established itself, more and more series-produced individual parts made of plastic became established in passenger cars. Innovations in vehicle construction were still aimed at reducing weight, fuel consumption and emissions. These goals were also favoured by polyurethane, which offered itself as a versatile and elastic material for vehicle construction. In 1979, Krupp-Kautex prepared machines for the production of extrusion-blown bellows for the first time, which were also made from polyurethane and no longer just from rubber. In 1981, the first blow-moulded rear spoilers and bumpers for passenger cars were produced on Krupp-Kautex blow-moulding machines.

The company responded to the increasing demands that were placed on the production of the new products from the 1980s onwards for environmental and health protection reasons. Barrier properties of plastic fuel tanks (KKB). An important milestone in this decade was the sale of the world's first six-layer CoEx system for fuel tanks. The Multilayer process for fuel tanks, but also for food and chemical packaging, became established as a fully automated production concept.

Times of change

The Krupp-Kautex era ended in 2000 with the sale to the Swiss SIG Group. After four difficult years for Kautex, the shares were transferred to the financial investor Adcuram in 2004. With Adcuram, Kautex Maschinenbau entered a period of organisational innovation and a time of conscious change and courageous exploration of new paths. With a new management team, Kautex Maschinenbau was able to regain its position at the top of the leading blow moulding machine manufacturers under its own steam and was able to assert itself in the rapidly growing Asian market in particular.

Since then, the management has been in the hands of Dr Olaf Weiland and Andreas Lichtenauer. Both are engineers with extensive sales experience. Weiland had already worked for Kautex Maschinenbau in the 1990s before moving to Hamburg in 1998 to modernise and expand sales and customer service at the sister company Krupp Corpoplast (now KHS Corpoplast) based there. Lichtenauer was responsible for expanding the Kautex business in China until 2004. He now has over 30 years of professional experience in blow moulding machine construction.

Following further changes of investor between 2007 and 2018, the majority stake is now held by a non-financial investor for the first time. The company sees the recent acquisition by Plastech Beteiligungs GmbH as a decisive step in setting the course for the long-term development of the company alongside a main shareholder characterised by a medium-sized company.

The company is particularly pleased with its focus on the plastics technology sector, on profitable growth through customer orientation, innovation and digitalisation - and on the basis of a long-term entrepreneurial approach.

The company today

In recent years, Kautex Maschinenbau had invested a great deal of energy and concentration in expanding its technological and market leadership in tank blowing systems. This has increasingly determined the external perception of the brand. The company has always developed, built and sold High-performance packaging machines.

To illustrate this, Kautex Maschinenbau presented a high-performance machine for the production of HDPE bottles at K 2007. The KLS6 on show had twelve cavities and produced 5,800 bottles per hour, for the first time in three different colours simultaneously.

At the following K 2010, a KLS8 was presented, for the first time not as a single blow moulding machine, but as part of a complete and fully automated production line, including quality control, labelling and palletising. While hydraulic systems were still used for the motion sequences in these machines, Kautex Maschinenbau made a decisive improvement at K 2013 and presented a machine from its new, all-electric KBB series.

The KBB60 on display attracted the public not only because of its high-quality appearance and its fast but smooth process movements. The machine radiates precision and perfection down to the smallest detail. Compact dimensions, extremely short cycle times and an energy recovery system make it a new benchmark in its segment. The latest measurements of energy consumption in accordance with Euromap 46.1 standards are proof of its success: numerous KBB machines already achieve the highest energy efficiency classification 10.

Innovative, digital solutions

In line with the Industry 4.0 megatrend, so-called IntelliGate modules the downstream has become an integral part of the machine. Thanks to this networking, complete production systems can now be created at the customer's request. A key component of the IntelliGate integration system is the newly developed Connext interface. This integrates downstream processes, such as quality inspection procedures, into the machines. The individual modules can be customised by the Kautex experts for machines in the KBB series and connected via the Connext interface using plug & play. This provides Kautex customers with a complete, integrated production process from a single source.

Another digital solution is training on virtual aircraft. Prospective pilots complete their first training hours on a flight simulator before they are allowed to take the controls of a real aircraft. Such training simulators have also been available for blow moulding machines from Kautex Maschinenbau since 2013.

This is a practical training tool that supports the Exact simulation of realistic production processes is now possible. The compact workstation unit, consisting of a simulation computer, two monitors, a projector and an original control panel, is now in its second generation and is available for various series.

[infotext icon]Kautex Maschinenbau has experienced above-average growth over the last twelve years. Compared to 2006, when turnover was around 60 million euros, the company achieved a turnover of around 144 million euros in 2017[/infotext].All pictures: Kautex Maschinenbau GmbH/Dr Reinold Hagen Foundation