Robatech from Muri, Switzerland, will be showcasing cooperation solutions at CCE International from 12 to 14 March 2019 in Munich. In cooperation with W. H. Leary, complete application and monitoring technologies for folding carton production will be on display. ENPRO is the cooperation partner for gluing solutions for shipping carton production.

The Laser 1D code reader from W. H. Leary can scan whether quality features such as Barcodes are correct or the Adhesive has been correctly applied to the packaging. Faulty products are ejected from the production line.

Robatech shows among other things his Cold glue head „SEMPRE“ and the SX Diamond„ hot melt head“. Both glue heads can be used in combination if the Tamper evidence flaps of packaging cannot simply be glued with dispersion adhesive. Instead, hot melt glue is also applied.

Cold glue head applies dispersion adhesive quickly and precisely

The „SEMPRE“ cold glue head offers product features that are epitomised by the abbreviation of the product name: „Speed, Electro, Mini, Precise“. The compact application heads in the new product range offer fast, precise and electronically controlled adhesive application. SEMPRE replaces the ECX Platinum series for the contactless application of low-viscosity adhesives. Dispersion adhesives from.

Robatech is also promoting the „SpeedStar Diamond“ hot melt head. According to Robatech, this provides a fast, precise and very thin glue application that is unique in the industry. Dot or bead application. Among other things, this solution is ideal for Attachment of package inserts. Combined with Melters from the Concept series such as the tankless „Concept Stream“, a high-performance hot melt solution is created.

Cost-saving application of pressure-sensitive adhesive closures with just one adhesive

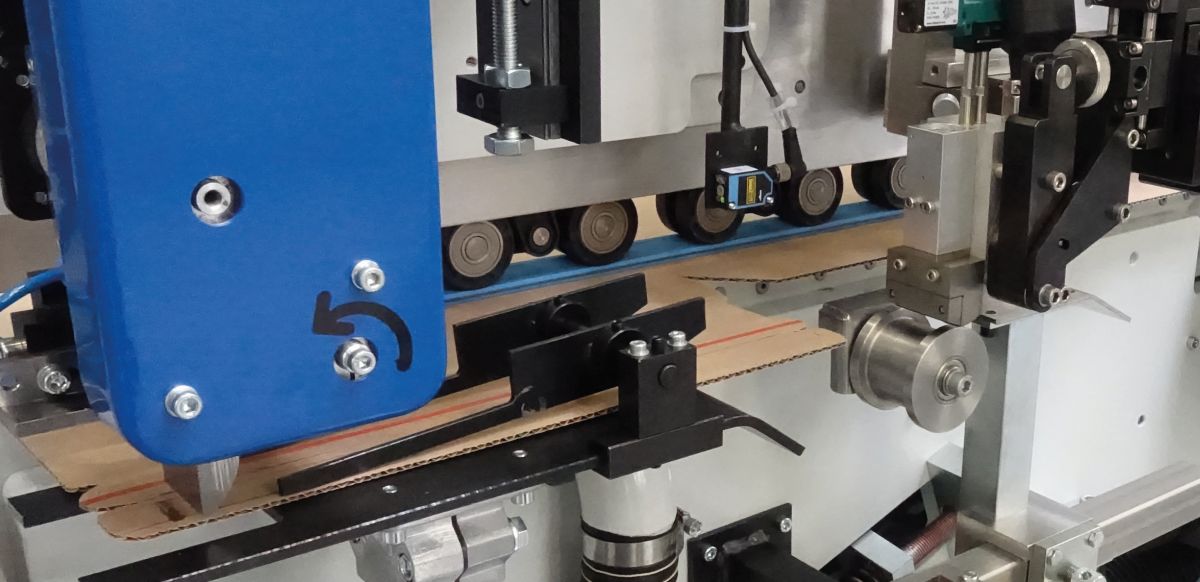

In co-operation with the company ENPRO Robatech provides a cost-saving complete solution for the Application of pressure-sensitive adhesive closures before. The application is suitable for applying pressure-sensitive adhesive seals to envelopes or shipping cartons. It consists of the Robatech Concept or JumboFlex melter, an FK-IT application head for the surface application of pressure-sensitive adhesive and the SPA silicone paper applicator from ENPRO.

The benefit of this type of application solution compared to the application of double-sided adhesive strips is that the application process is much faster and cheaper. The following are achieved Production speeds of 200 metres per minute. The application quantity can be individually adjusted depending on the surface and the expected stress on the packaging. This makes it possible to use one and the same adhesive for different packaging materials.

Robatech at CCE International 2019: Hall B6, Stand 446