Constantly reinventing yourself and being flexible: The history of papermaking in Uetersen near Hamburg in Schleswig-Holstein goes back over 100 years. The name Feldmuehle is firmly (and proudly) anchored in it.

Numerous Change of ownership and name accompanied the development of the paper mill. This is precisely why change and adaptation as well as the ability to find good answers to new challenges are part of the company's self-image. Customers who still rely on paper from Feldmuehle today benefit from this experience and a flair for innovative products - both regionally and globally.

Since 1904 paper is made in Uetersen: Firstly newsprint for publishers in nearby Hamburg, later double-sided coated format papers and single-sided coated label paper. Today, Feldmuehle Uetersen GmbH offers High-quality white papers in a wide rangeLabel paper, flexible packaging paper and coated top liner, pulp board and picture printing paper.

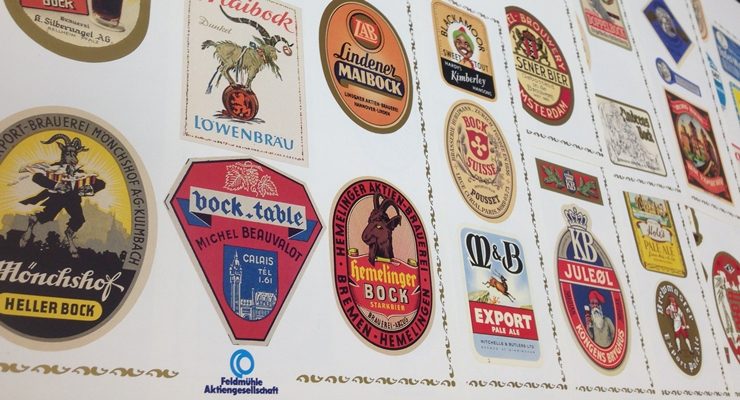

[infotext icon]The company, with its Label papers as a reliable and competent partner, especially for the Beverage and food industry firmly established with well-known brands[/infotext].The name Feldmuehle stands for High product quality. This is guaranteed by the excellent expertise and experience of our employees. Standards are constantly being set in the development of new products, because innovation is a tradition at Feldmuehle. Only pulp from sustainably managed sources is used for paper production in Uetersen. The company is certified in accordance with the demanding FSC®- and PEFCTM-Standards certified.

„For us, being particularly close to our customers means listening, understanding and advising them as equals. Our strength as a medium-sized company is our ability to react flexibly to individual and special customer requirements,“ emphasises current Managing Director Heiner Kayser.

Through wars and crises with newsprint

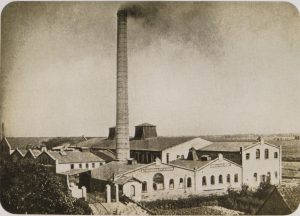

In 1904, both the Hamburg newspaper publisher Hirt and the wealthy glue manufacturer Jenß bid on the site of a cloth factory on the banks of the Pinnau in Uetersen. Joachim Ernst Jenß finally acquires it, but together they build the paper factory that is still located there today under the name of North German paper mill Hirt and Jenß.

As early as 1906, the Production of newsprint, initially on one, and two years later on a second paper machine. In the following years, the conditions were created to meet the steadily increasing demand for paper at this time: A steam turbine, wood grinding plant, new wharf facilities and loading cranes accelerated the work processes at the mill.

In 1913, the now new owner, Papierfabrik Kabel GmbH, and the Papierfabrik Reisholz Aktiengesellschaft, together. The new company traded under the latter name when the First World War broke out on the threshold of a promising development of the factory. For the plant in Uetersen, this initially meant a complete shutdown before production could be resumed in 1915, primarily with printing paper. The paper industry also felt the effects of the global economic crisis from 1929 onwards: in this year, the companies Papierfabrik Reisholz Aktiengesellschaft, Düsseldorf, and Feldmühle Papier- und Zellstoffwerke Aktiengesellschaft, Stettin, merged. The company name was now Feldmühle Papier- und Zellstoffwerke Aktiengesellschaft, Uetersen mill.

At the beginning of the Second World War, the plant and its 200 employees were closed by the government. Reconstruction and renovation did not begin until 1947, after the post office had vacated its temporary warehouse on the factory premises. Initially with five workers and two employees, the Production of newsprint, bag and wallpaper base paper resumed. The number of employees increased again to over 200 in the course of 1948.

High-quality magazine paper displaces newsprint

The 1950s saw the expansion and modernisation of the mill. As the demand for glossy paper for magazines rose sharply, the Product range expanded in 1950 to include satinised papert. The steady increase in sales also made it necessary to modernise all areas of the mill: New calenders and a corresponding extension with a sorting hall created the conditions for increasing the mill's paper output by 60 per cent. By the end of 1953, the conversion and expansion into a modern plant, which now operated under „Norddeutsche Papierwerke GmbH“ was completed. The centrepiece was the installation of the new paper machine 2, including the expansion of the machine room and the grinding shop. From the beginning of the 1950s, it was also possible to deliver wood and pulp to the mill site by ship.

Start of machine coating and the production of label papers

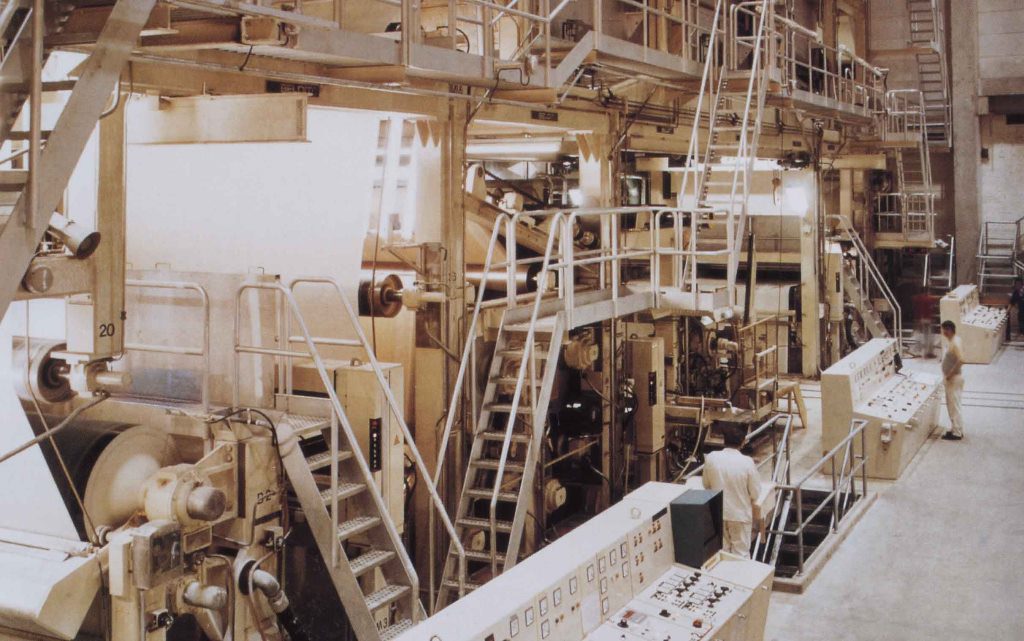

In 1959, Uetersen was the first plant in the Feldmühle Group to be equipped with a machine coating facility - the beginning of the modern Surface finishing of papers from Uetersen and the cornerstone of the mill's traditionally high level of coating expertise. In 1963, the mill was one of the first European paper manufacturers to be equipped with a doctor blade coating machine. In 1966, the production of one-side coated label papers began and the mill quickly became a leading supplier. In 1976, the mill was equipped with a modern coating device for the simultaneous coating of printing papers on both sides in online operation. This made it possible to increase capacity by 25,00 tonnes per year to 90,000 tonnes.

Art paper and increasing production

After the production of magazine paper was transferred to the Feldmühle site in Hagen in 1978, the Uetersen High-gloss picture printing papers produced. A new coating machine, embedded in a new 24 metre high coating machine hall, ensured the production of high-quality art paper.

In the 1980s, the mill becomes the Feldmühle centre for double-sided coated wood-free art paper and single-sided coated label paper. At the same time, the proportion of Format papers, This required numerous expansion measures that are still important today, including a new building for the sizing equipment with several cross cutters.

The machinery makes it possible to respond particularly flexibly to individual customer requirements.

The Stora Enso era: growth and a move into new markets

In 1990, the Swedish paper group took over the Stora the total of seven German Feldmühle factories. When Stora merged with the Finnish Enso Group in 1998, the plant in Uetersen became part of the Stora Enso Fine Paper Division. Significant investments were made in order to utilise the growth potential of the higher basis weights and to expand production capacity: Paper machine 2 and coating machine 2 were converted to be able to offer basis weights of up to 350 gsm. Since 2004, matt picture printing papers have also been produced in Uetersen in addition to glossy papers.

Another milestone in the history of the site is the Strategic focus on speciality papers since 2011, after the production of graphic papers with low basis weights was moved to Finland. The Uetersen mill made a virtue out of necessity and today Feldmuehle benefits from the intensive product development and further development of the product portfolio during this time: flexible packaging papers, high-quality liner and pulp board have been introduced since 2012.

[infotext icon]Recovery of raw materials through separation technologyIn 1992, the „Separation technology“ developed a process for recovering raw materials: This means that fillers and pigments recovered from waste water can be used again in paper production. For this process, the Uetersen mill was awarded the Environmental Protection Prize of the Federation of German Industries[/infotext].

The new Feldmuehle: Traditional strengths meet developer spirit

Since the Release from the Stora Enso Group In 2015, the Uetersen paper mill with its more than 400 employees successfully went its own way. When choosing a name for the new medium-sized company, the decision was made to use the Return to the traditional name. The Feldmuehle Uetersen GmbH offers its international customers high-quality white coated papers in three business divisions: Labelling Applications, Packaging Solutions and Graphical Options.

In the production of graphic papers, the mill's longest tradition, the company is now increasingly focussing on pulp board and high-white, premium-quality art paper. These are used for a wide range of applications such as folding boxes, illustrated and art books, catalogues, magazines, inserts, brochures, postcards and admission tickets.

With decades of experience in the production of high-quality labelling paper, Feldmuehle is one of the leading suppliers. Around one in three labels on bottles and jars in Germany alone is printed on paper from Uetersen. But nobody at Feldmuehle wants to rest on their laurels: As a trendsetter, the aim is to continually expand the extensive, high-quality range with innovative products.

Ambitions as a newcomer in packaging

Feldmuehle is breaking new ground with its relatively new products in the field of flexible packaging papers and liners for the laminating and corrugated board industry. For around five years, the company has been offering numerous solutions for sales-boosting packaging or displays as well as a wide range of applications in the food sector, such as wrapping paper for chocolates, yoghurt pot sleeves and outer packaging for tea bags and coffee.

Heiner Kayser has been Managing Director of Feldmuehle Uetersen since May 2017. He emphasises: „Our aim is to be an innovative and forward-looking Partner to customers who can realise successful applications with our products. We want to continue to set new standards - with consistently high quality and in the development of new papers.“

The aim is to offer the market new and High-quality product solutions to offer. The fact that this is possible thanks to the company's development strength is demonstrated, for example, by the innovative papers with Mineral oil barrier, which were introduced this year: They ensure effective protection of the packaged goods against mineral oil migration and contamination and are suitable for modern packaging with direct food contact. Brand owners are already successfully using these products for packaging dry and fatty foods.

Another innovation are the various Heat-sealable papersThese paper solutions provide packaging manufacturers and fillers with a material that consists mainly of renewable raw materials and can be used on existing packaging machines. The products are suitable both for high-quality printed packaging and for inner bag solutions with a natural paper feel.