At Labelexpo 2019, GSE will be showcasing a new automation system for its Colorsat dosing systems based on Windows 10. The Dutch company will also be presenting new functions for its „Ink Manager“ software at the trade fair in Brussels.

The new functions of the Ink Manager software packaging and labelling manufacturers a more efficient, secure, precise and flexible production process. Printing ink management in all workflow phases from purchasing and mixing to recycling and reuse, GSE reports. The provider for Printing ink logistics from Brummeln in the Netherlands has expanded the programme package to include functions for reporting, planning and machine connection.

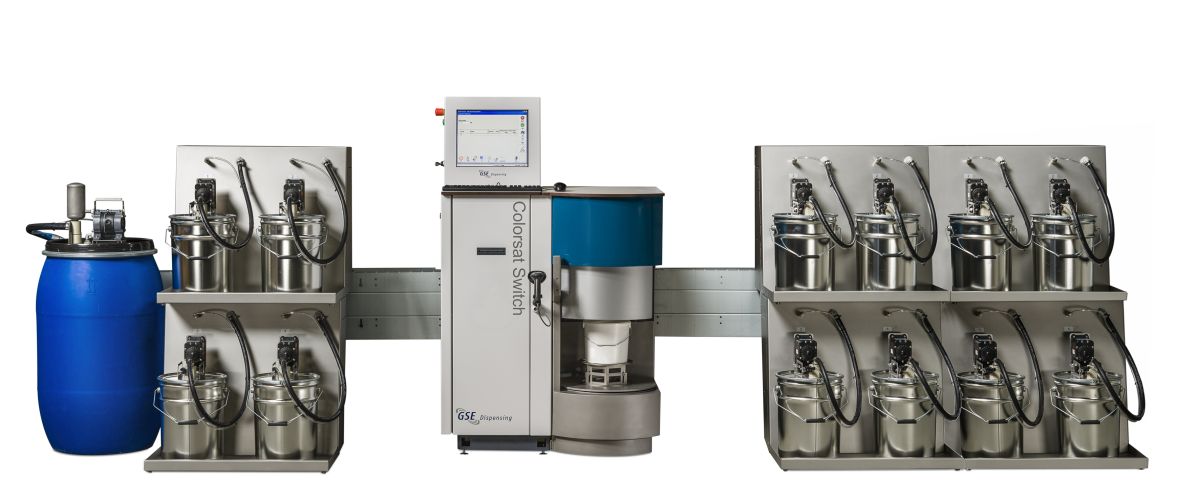

Colour dosing systems now dose even more precisely

Maarten Hummelen, Marketing Manager of GSE, describes the advantages of the product innovations: „The introduction of Windows 10-based controls with the new software version makes it easier to connect the Colorsat dosing systems to other machines and software with less labour and risk of errors. The control system is more compact and has fewer components, is easier and more efficient to maintain and is offered with security updates for at least ten years. We have also developed a Windows 10 upgrade package developed so that existing Colorsat appliances can be equipped with the new control technology.“

In principle, the Pneumatics of the new control system more robust. The same valves are now used for all dosing systems in the Colorsat range, explains GSE. The Responsiveness of the system has been improved. Users can now dose more precisely and benefit from better colour accuracy.

Ink yield improved by up to 30 per cent

The Colour dosing systems of the Colorsat series are used for fast and precise mixing and dosing of flexographic, gravure and screen printing inks for labels and packaging, according to GSE. UV inks, water-based inks and Solvent-based paints would be covered. The advantages include shorter set-up times, up to 30 per cent better Ink yield, more cleanliness in the colour laboratory and better inventory management. Labels are dispensed using a replacement container and a refillable storage container.

„Supply chains require smaller production runs, traceability and shorter lead times. Packaging and labelling manufacturers must therefore not only eliminate waste in workflows, but also speed up processes and limit manual intervention to high-value work wherever possible.“

Maarten Hummelen, Marketing Manager of GSE

Better traceability with new software features

The software „Ink Manager“, a solution for ink waste reduction and business planning, is said to provide more information about the performance of the ink management system. It improves the Traceability, This is because it creates inventory data when purchasing or returning printing inks, which can then be used to generate easily accessible information on expiry dates, suppliers, batch codes and quantities used per order.

In addition, options such as the control of automatic conveyor belts, mixers and agitators or the planning of mixing times per recipe are advertised. The software also offers grid functions such as filter lines, search fields and totalling lines. The Ink Manager software has a modular structure. Customers can also request features such as integrated data export, Residual colour return, order management, tracking and tracing Supply chain management add.

[infotext icon]You will find GSE at Labelexpo Eurpe 2019 in Brussels at stand 7D59. More information about the company can be found on the homepage

http://www.gsedispensing.com