The core expertise of SIKO GmbH, Buchenbach, lies in solving a wide range of measuring tasks: length, angle and speed measurement technology as well as measuring inclination or speed. Building on this expertise, the company develops and produces pioneering measuring devices and positioning systems, including for automation processes in the packaging sector.

The demands on the flexibility of modern production systems are constantly increasing. With a wide variety of products and ever smaller batch sizes, the need for flexibility is becoming increasingly important. Optimised system availability into focus.

Short set-up times are therefore a standard requirement for production and packaging machines. Manual or monitored format changeovers often reach their limits here. The next step is logically the Complete automation adjustments via compact drives without manual intervention.

There are two reasons in favour of automation: On the one hand, the changeover times are significantly reduced, which is particularly interesting for frequent product changes. On the other hand, there are often axes that Difficult to access or can only be reached by removing panelling parts.

pj: Mr Schuh, automation with actuators is exclusively concerned with spindle adjustments, as the Actuator a purely rotary system is. How do compact Positioning drives for simple automation of existing adjustment axes?

Jürgen Schuh: Actuators are characterised in particular by their Compact design and can be connected directly to the control system. The customer also does not have to adapt the mechanical design, which was intended for manual format adjustment, for the drive.

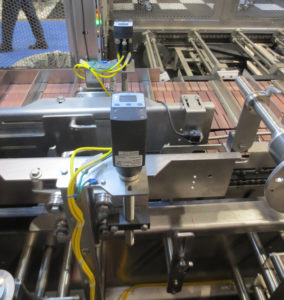

Simply attaching the hollow shaft to the spindle enables automated adjustment. Space is often very limited in the machine units, which means that devices are required that can be used in a small space despite their small size high performance and extensive functionality have to offer. Siko's compact actuators clearly stand out from other systems.

pj: The range of format adjustments is relatively wide. Which Performance classes are available for the various applications in practice?

With a maximum nominal torque of 14 Newton metres, the AG24 positioning drive is a real powerhouse for format adjustment. (Image: SIKO GmbH)Jürgen Schuh: For packaging machines, where Complete feeding systems for cardboard boxes Depending on the packaging size, the width must be adjusted, i.e. entire machine units must be moved. Relatively high torquesthat can exceed ten Newton metres. The AG24 is suitable here as a larger siko drive.

In the medium power range there is a Wide range of adjustment requirements. Another classic in the packaging sector are the so-called Carton erector. Drives in the power range between 50 and 70 watts, such as the AG25, are suitable for these applications.

pj: How does the Process data exchangeand what should I pay particular attention to?

Jürgen Schuh: Thanks to various standard interfaces Direct communication with the higher-level machine control system (PLC) is possible. This acts as a control centre that specifies the target values and the start command to the drive. However, the control of the fully automated positioning in terms of target value and speed takes place within the drive.

The so-called process data, i.e. Position, speed, direction of rotationare then provided continuously and can also be read out by the control unit. This function is important for the Monitoring and diagnostic optionsif irregularities or errors occur.

pj: Which possibilities of Parameterisation are available?

Jürgen Schuh: The simplest parameter is the Determination of the adjustment in millimetres. In addition, it is also possible to Acceleration and braking ramps This allows you to programme how quickly the drive accelerates and how quickly or slowly it brakes again. Other control parameters can also be set, for example to correctly position different masses with different moments of inertia.

The many parameterisation options offer the machine manufacturer A great deal of flexibility and functionality. All can be variably set via the bus interface or configured directly on the actuator using programming tools if access via a bus interface is not possible due to a lack of availability of the controls.

pj: Keyword Predictive maintenance: What does this mean in this context?

Jürgen Schuh: Behind this aspect lies the Diagnostic capabilitywhich is integrated in the actuators. Various display values and actuator parameters can be used to Conclusions about the operating status of both the drive and the system in general in order to recognise irregularities or maintenance requirements at an early stage. The diagnostic values Current, temperature and voltage provide information about this.

Of course, the data is also reported back to the higher-level control systemso that the temperature, for example, can be continuously monitored and appropriate measures can be planned. There are also safety measures in the drive that disconnect the drive from the mains if the current or temperature exceeds limit values in order to prevent damage. In this case, however, it is no longer a matter of "predictive maintenance", but rather "Immediate Maintenance", rather "Preventive maintenance".

pj: Finally, could you please give us a few more challenging and interesting Examples from practice briefly?

Jürgen Schuh: I don't want to emphasise any particular example here. Because even if the conditions can be very different, the task and the benefits are always the same in principle: the customers' packaging machines are equipped with spindles that have to be adjusted to a new dimension when changing products.

With ADCO in the USA folding boxes, for example, are erected before the goods can be inserted. If the packaging format changes for a different product or a different filling quantity, the machine must be set to this new size.

The original manual adjustment involved cranking by hand until the setting was (hopefully) correct. With our actuators, this is done Everything at the touch of a button via the control system (PLC) and much faster. The machine body does not even need to be opened. The spart money and is absolutely Process reliableThis is because the stored values and full automation rule out possible incorrect settings that could be made by human operators. The same principle also applies to other packaging machine manufacturers.

Siko at FachPack 2019: Hall 3, Stand 140