Icing is the icing on many baked goods. It is usually applied by hand in complex production steps. Most gingerbread decorating today, for example, is still done manually with a piping bag.

Increasingly, however, the bakery industry is also using the Degree of automation increased. There are several reasons for this: Stricter Hygiene regulations or high Personnel costs for example.

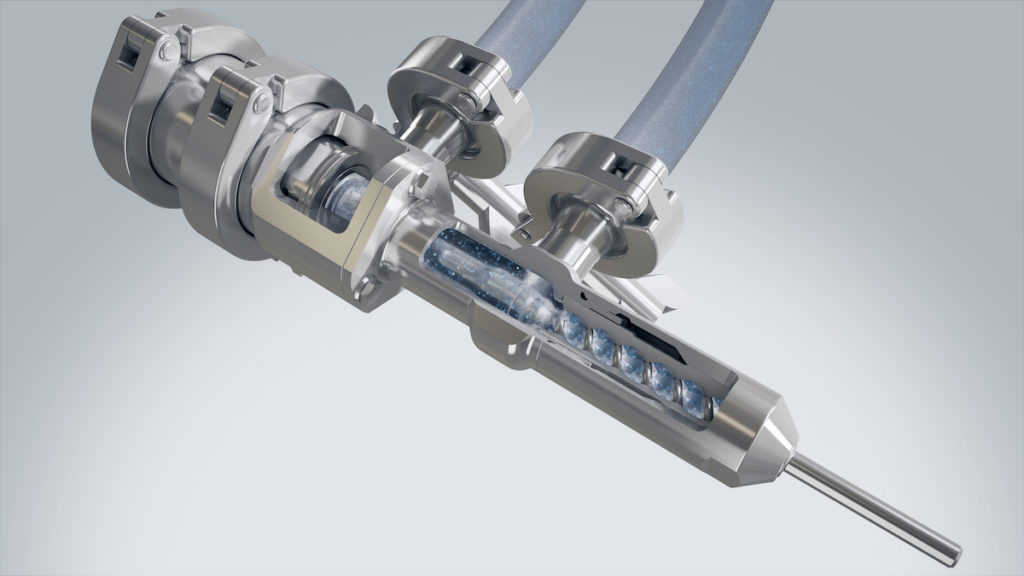

With the Endless piston technology, on which the dispensers and dosing pumps from ViscoTec are based, can be used for decoration tasks or filling in the confectionery industry. Semi-automatic and fully automatic realise.

Biscuit labelling 2.0

Automation in the confectionery industry, or in the production of baked goods, cannot be compared with automation options in other industries such as the automotive industry. Instead of a standardised component with defined production tolerances, here Worked on the „living product.

As no two baked goods blanks are completely the same, this type of application requires Advanced camera technology. In order to be able to react to the moulded part deviations in real time, it is necessary to flexibly adjustable dosing technology.

With ViscoTec dosing technology, the necessary parameters such as discharge quantity, speed, etc. can be adjusted to suit the application. anytime and analogue during the dosing process.

Especially for highly viscous or difficult foodstuffs such as Icing the progressive cavity pump offers outstanding possibilities. Thanks to its simple handling, the dosing pump can be used in automation solutions and integrated into all common robot systems.

Application example of automatic cake decoration with VARO

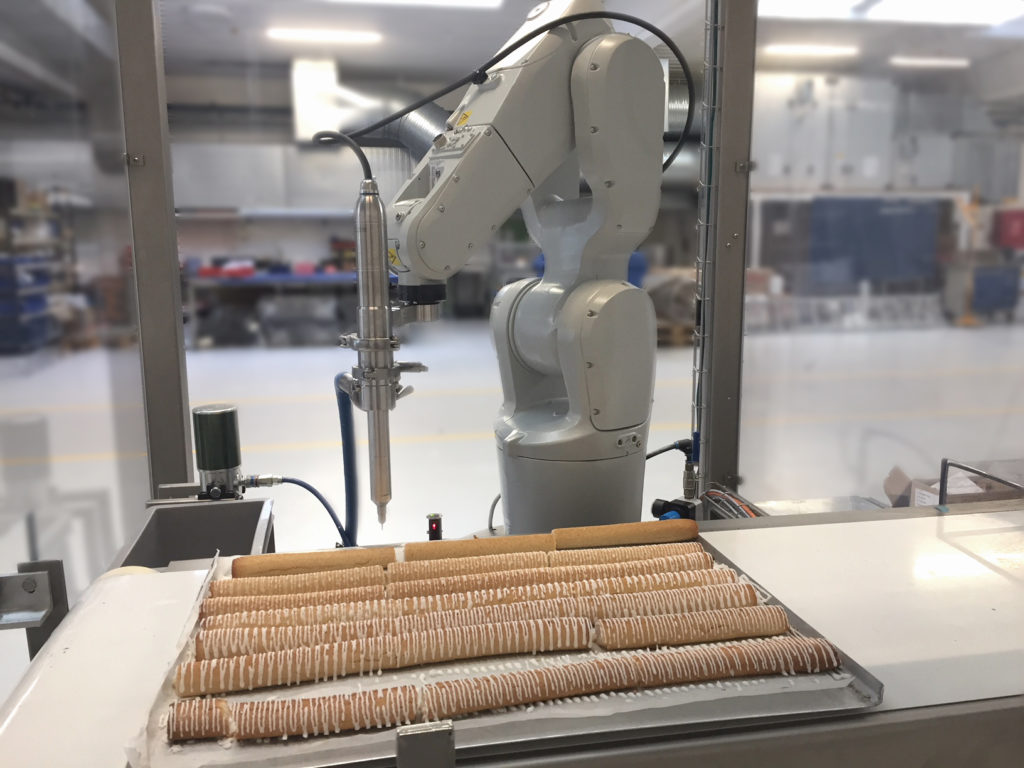

A typical application is the fully automated decoration of biscuits, pastries and small cakes with icing. In a system from VARO, a machine and system manufacturer for production companies in the pharmaceutical, food and non-food sectors in Denmark, a ViscoTec VHD Dispenser integrated.

The food robot automatically decorates various baked goods. The result is a Efficient, continuous and flexible pastry decoration.

„One key to success is controlling the decoration processes. With the use of the ViscoTec Hygienic Dispenser, we not only obtain a Precise control of the flow rate, but also a system that is durable and easy to clean. Our direct collaboration with ViscoTec ensures the best solution in every case.“

Arne Lundfold Bjerring, Head of Engineering at Varo

The robot can dispense different patterns, even Freehand drawings. Specially developed robot software converts the Sketches in robot paths around. In conjunction with a Camera system the dispensing system automatically recognises which piece is next in line and which pattern is to be applied to it.

The VARO system can apply different decorative patterns in one and the same process - both warm as well as cold. It convinces through absolute Simple operability. And is compatible for all types of pumpable decorations such as glaze or chocolate and fruit sauce.

Perfect filling results

Another possibility, in which progressive cavity pumps are used in a completely new environment, are Filling applications in the confectionery sectorWhere simple piston dosing systems still reach their limits (e.g. due to excessive viscosity), the applications are either used under extreme technical, and therefore also cost-intensive effort realised.

In this case, the eccentric disc pump can be used as a Dosing or filling pumpe to be used. Difficult and highly viscous media, such as. Honey mixtures can be easily dosed and filled.

In addition, confectionery manufacturers have the advantage of being able to offer New products and blends and can now finally be produced because the technical possibilities were simply lacking in the past.

The highly viscous liquids, such as. Pastes or creams are dosed extremely gently and their structure is not changed. Here too chunky mixtures, for example, pieces of fruit or small biscuits can be pumped effortlessly.

Depending on the application, the dosing pumps can be mounted directly on a fully automated filling station or can also be installed in a stationary and semi-automatic system, for example.

Both decoration and embellishment applications, as well as filling applications, are comparatively simple. New areas of application for progressive cavity pumps in the food sector, which enable users to automate and completely restructure processes.

Source: ViscoTec Pumpen- u. Dosiertechnik GmbH