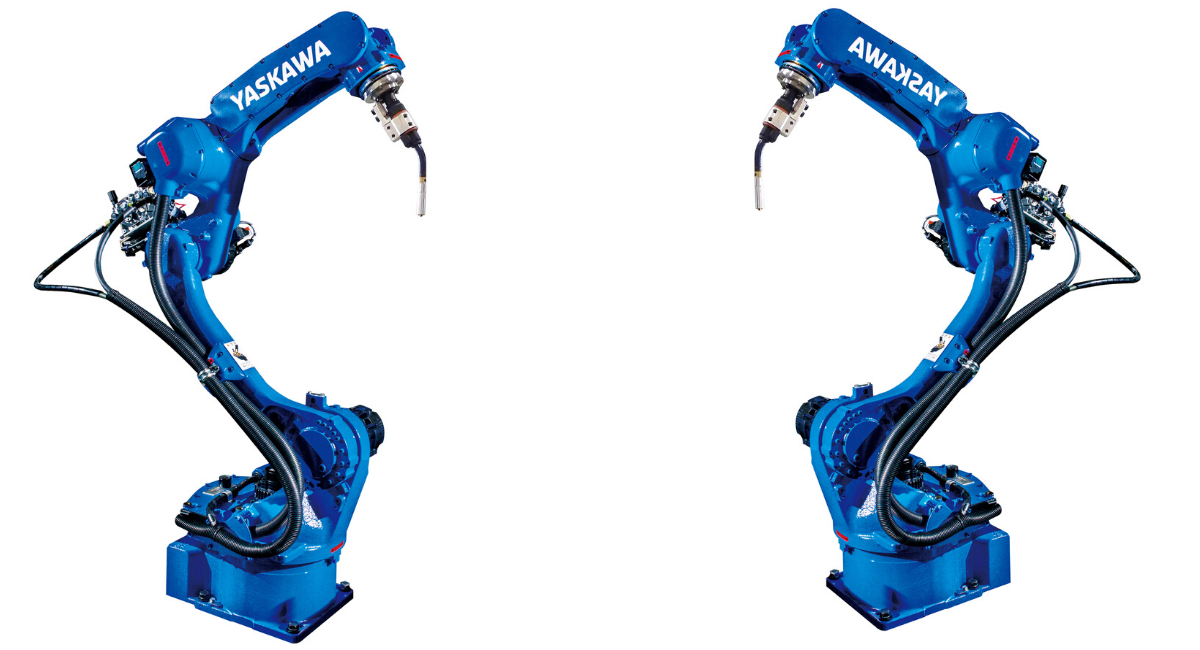

Yaskawa is expanding its welding robot portfolio with six new models in the Motoman AR series. With working ranges from 727 to 3,120 mm, they can process a wide variety of workpieces and assemble a large selection of accessories.

The precise 6-axis robots of the AR series from Yaskawa have been specially developed for the high demands of arc welding. They enable the user to Shorter process times, which in turn leads to a increased efficiency and energy savings leads.

Six welding robots that impress

The two compact Motoman AR700 and Motoman AR900 robots impress with their high welding quality and repeatability. The two robots are suitable for simple welding applications, mostly with shorter weld seams, without a great deal of programming effort, such as tacking or welding of pre-assemblies.

The Motoman AR900 can also be installed in the recently introduced, turnkey robotic arc welding cells in the ArcWorld portfolio. The ArcWorld cells' recipe for success is simple: AR700 or AR900 robot, 2-station manual rotary table, controller and power source. All components are combined on one platform to save space and are ready for immediate use, guaranteeing the welding of a large number of small workpieces to the highest Yaskawa quality.

The medium-sized Motoman AR1440 was specially developed for the high demands of arc welding in order to achieve optimum results under extremely difficult conditions. With its load capacity of up to 12 kg, space for the hose package with integrated media guide and a maximum working range of 1,440 mm, it enables easy processing of bulky and hard-to-reach workpieces while delivering high-quality results.

Thanks to the slightly curved design of the lower arm, welding seams can also be realised on components that are difficult to access. The air line and a media connection are integrated into the base, allowing a working range of 340 degrees to be realised for the 1st main axis (S axis).

The Powerful and dynamic Motoman AR1730 with its very high load capacity of up to 25 kg, offers optimum conditions for double wire or twin applications. In combination with its maximum working range of 1,730 mm, it offers the Highest drive performance in its class. The robot's fast movements reduce cycle times and its slim, slightly curved design minimises collisions between the fixture and the component.

The Motoman AR2010 impresses with its large working range of 2,010 mm and, with its high load capacity of up to 12 kg, is ideal for welding bulky and large components, for example vehicle frames, lorry tipper bodies, trailers or containers.

The largest and most powerful modelthe Motoman AR3120, covers a considerable working range of 3,120 mm. Thanks to its high load capacity of up to 20 kg, it is also ideal for welding bulky and large components. Its hollow arm design ensures that the hosepack is guided through the arm to the wrist, saving space and minimising wear.

High quality, productivity and web accuracy

All models in the Motoman AR series work with the flexible and fast YRC1000 high-performance controller for Motoman robots, which is also included in the scope of delivery. This extremely compact controller enables optimum space utilisation and contains helpful functions from over 40 years of experience that support the welding process.

Source: Yaskawa