On 11/12 December 2019, numerous companies from the medical device sector will meet at the GS1 Germany Knowledge Center in Cologne for the UDI (Unique Device Identification) Practice Day, which GS1 offers exclusively for its solution partners. The aim is to find and concretise new joint solutions for the identification and labelling of medical devices and in-vitro diagnostics (IVD). Bluhm Systeme GmbH and Cognex Germany Inc. will be there as GS1 partners and full-service providers for labelling solutions and image processing technologies and will jointly present their ideas for the future of medical technology.

Patient safety has priority

An essential prerequisite for this is the Clear identification and seamless traceability of medical devices and in-vitro diagnostics. With the Unique Device Identification System, the EU is therefore planning an obligation to identify and register medical devices from 2022 that goes far beyond what is currently required.

In future, a more broadly based EUDAMED database, which „European database for medical devices“,This is intended to improve the transparency and coordination of information on medical devices available on the EU market. This will significantly increase the traceability and identification of products, which will ultimately serve to ensure faster processing of corrective measures such as recalls, including official notifications.

On 11/12 December 2019, the UDI Day will focus on the latest Unique Device Identification (UDI) requirements, identification and labelling solutions as well as entering product information into the UDI database. The participants will learn First-hand tips and tricks.

What do companies in the medical device sector need to know?

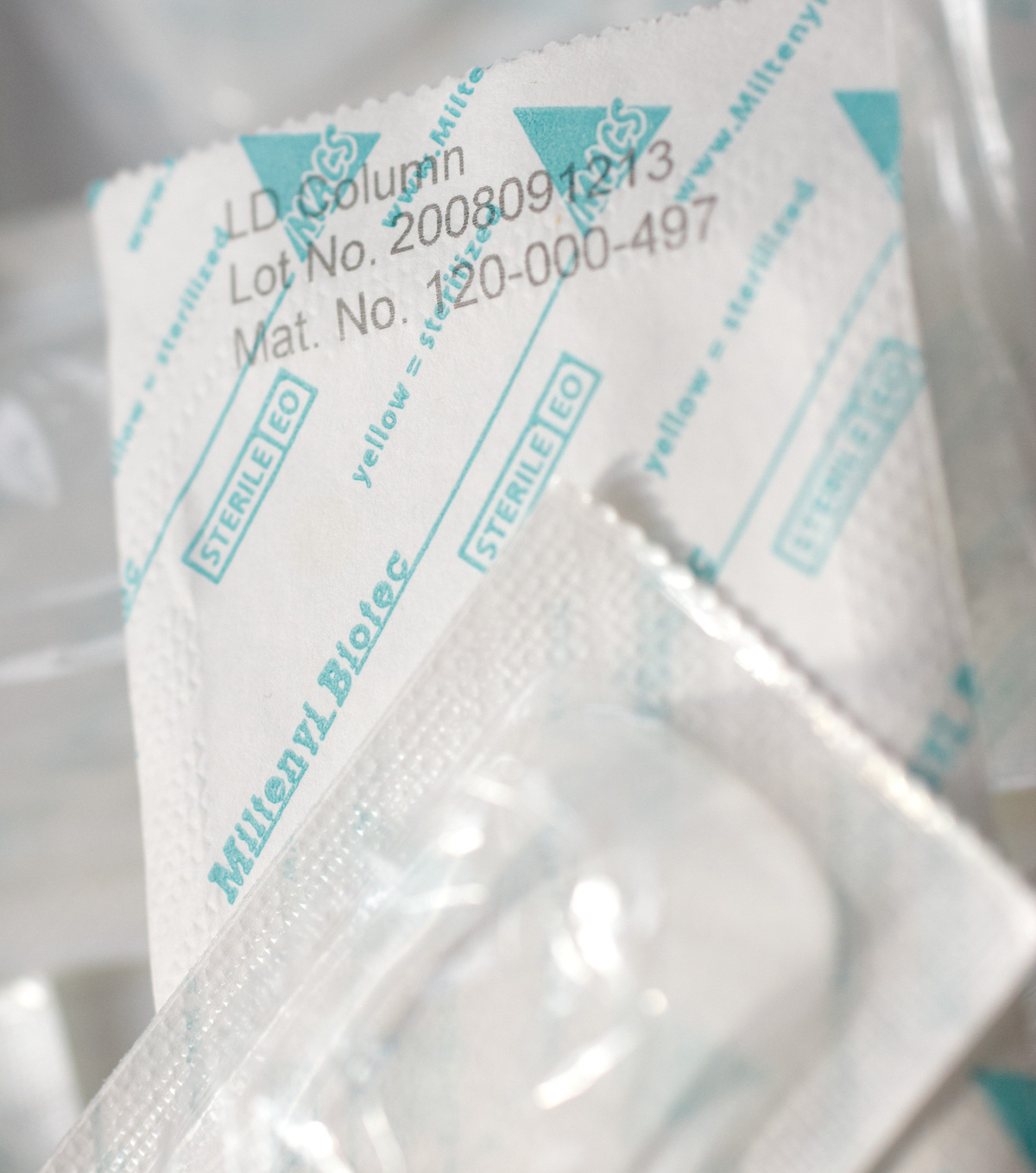

From May 2020 at the latest, all medical devices must be labelled with a unique identification mark that can be traced throughout the entire supply chain. UDI code (UDI = Unique Device Identification) be labelled. The UDI code consists of two parts - a product identifier and a production identifier.

The first part is used to identify the manufacturer and the product (also reference code) and is a globally unique product code, with which a product can be uniquely identified. This is also stored in the central database.

The production identifier, on the other hand, is not mandatory and consists of optional dynamic information such as batch or lot numbers, serial numbers, expiry or manufacturing dates, etc. It is specified that the UDI identifier must be applied in two forms: Once in clearly legible plain text (HRI/Human Readable Interpretation) and in the AIDC format (Automatic Identification and Data Capture), i.e. machine-readable labelling in the form of a code (optionally barcode or 2D code).

The machine-readable portion is either linear barcode or as a two-dimensional data matrix code displayed. The plain text part can be represented in the form of numbers and letters. Furthermore, the UDI code consists of a static and a dynamic part: the static part is a unique, specific code for the respective product, the dynamic part changes with the variable information such as serial number, product batch or expiry date.

Which method is suitable for labelling?

The most important requirement: the labelling must permanently legible be. The code must remain legible over the entire service life - this is particularly important for reusable surgical instruments, for example, which have to withstand many cleaning cycles. Bluhm Systeme has tested all common processes.

At the UDI workshop, the labelling expert will show all samples consisting of paper, film and metal that have been labelled using four different processes. These include conventional label printing, inkjet and thermal transfer printing and laser labelling. All labelling processes demonstrate clear legibility. When it comes to labelling metal and laser foil, the Laser labelling for consistency.

Source: Bluhm Systeme GmbH