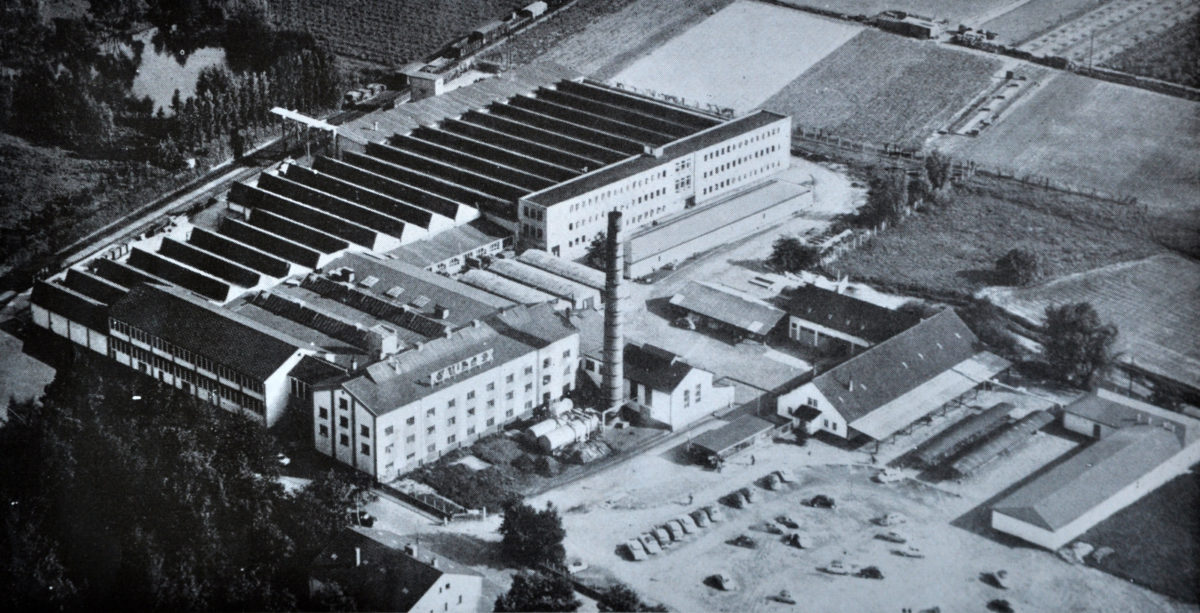

Kautex Maschinenbau is celebrating three anniversaries this year: its 85th anniversary, 60 years as a subsidiary in the USA and 25 years of machine production in China.

Plastics pioneer Reinhold Hagen founded the company in 1935, In 1949, he developed the world's first standardised system for the seamless production of hollow plastic bodies. In 1960, the company founded the first international Branch office in New Jersey, USA. 1995 saw the foundation of the first German joint venture in Shunde, South China.

Where the third generation of the Chinese KCC series is currently being built, other well-known series from the German site are to be produced in a localised production facility before the end of 2020. The aim of the Bonn-based company is to Shorten delivery routes and depending on the order to deliver the machines from Germany or China. Today, Kautex is one of the leading manufacturers of Extrusion blow moulding machines and has branches worldwide in Europe, Asia and North America.

While the first plastic hollow bodies were associated with increasing demand due to their positive properties, plastic products are increasingly being criticised nowadays. There is a lack of efficient recycling concepts. Kautex is therefore currently focussing on topics such as Sustainability, recycling and digitalisation is the focus of research and development activities. The latest developments in terms of sustainability are innovative technologies that drastically reduce the consumption of energy and raw materials - e.g. when changing colours and materials. At the same time, Kautex has been optimising the Processing of recycled plastics.

„The perception of plastic products has changed considerably in recent years. Sustainability arguments and the ecological footprint of products are playing an increasingly important role in their acceptance. We are therefore specifically promoting plastics recycling and the optimisation of material cycles,“ says Managing Partner Andreas Lichtenauer.

Marketing Manager Christian Kirchbaumer adds: „We are also working on using our technologies to further improve the carbon footprint of hollow container production. If we continue to actively contribute to linking the positive properties of these products with globally functioning recycling cycles, this will be a significant step towards a sustainable future for everyone.“

In addition to technological innovations, Kautex also focuses on digital services, to make production more sustainable. Customers can use the Augmented Service can utilise virtual services worldwide. The service enables teams of experts from all over the world to be contacted without the need to travel. virtual to the machine to resolve problems as quickly as possible. This reduces the service team's air miles and therefore also the CO2 emissions caused by such journeys. For training purposes, Kautex also uses digital simulators in. The „Digital Twins“ precisely model the processes of the machines and save energy and material consumption of the real machines.

Kautex Maschinenbau will triple anniversary in 2020 celebrate on various occasions. The highlight will be a Open House at the site in southern China in the last quarter of this year.

Source: Kautex