Coperion implements a closed-loop concept for the production of flexible multilayer films. Their production waste is 100 per cent recycled and fed back into the production process.

The Recycling of multilayer films has so far presented a challenge, as they are very difficult to recycle and cannot be recycled without leaving residues. Coperion has now found a solution for the Closed loop approach developed in which Multilayer film production waste 100 per cent recycled and fed back into the production process in a closed cycle.

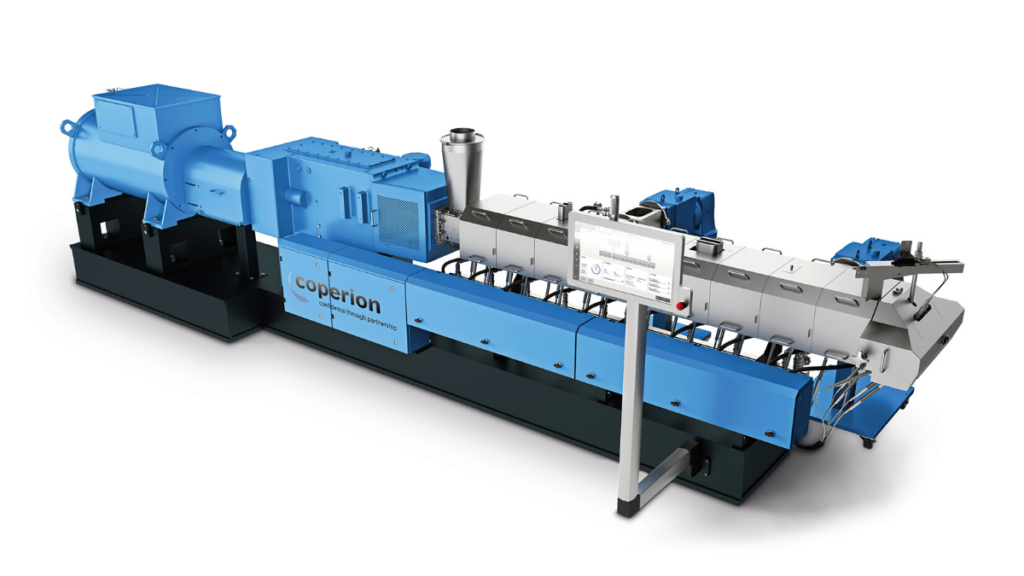

For a specific project, Coperion will develop a Recycling plant including bulk material handlinghigh precision Feeders from Coperion K-Tron and as the centrepiece of the system a ZSK Mc18twin-screw extruder deliver.

Closed loop with the help of the most advanced technologies

The multi-layer film waste that is generated during the production process is crushed in a first stepbefore they are pneumatic conveying and high-precision dosing from Coperion K-Tron into the ZSK extruder are fed into the extruder. There, the material is processed in the co-rotating twin-screw extruder ZSK Mc18 with very homogenised and degassed at high intensity.

In the extruder, dispersion and degassing performance are decisive for the quality of the end product - with a gentle working method and very good mixing properties, even in the case of Very high throughput rates. This is how a Consistently high product quality achieved.

After homogenisation in the ZSK extruder, the closed-loop concept is used to homogenise the melt back into the multilayer film production process whereby the recycled material is added to the film without any loss of quality is used. The proportion of recycled material fed into the process is very high. Multilayer films are therefore produced using the most advanced technologies Resource-saving, highly efficient and sustainable.

"Sustainability is becoming increasingly important, and the topic of the circular economy is becoming more and more prominent, especially for companies and in particular for producers of multilayer films. We are proud that we can contribute to a promising, forward-looking and sustainable closed-loop approach with our many years of process expertise and our visionary technological solutions," says Peter von Hoffmann, Head of the Engineering Plastics & Special Applications business unit at Coperion.

Source: Coperion