Siegwerk, one of the leading suppliers of printing inks for packaging applications and labels, and APK AG, a specialist in the production of high-quality plastic granulates from plastic waste, have successfully completed joint decolourisation tests on double-printed LDPE films.

Launched in October 2019, the Strategic partnership between the printing ink manufacturer and the recycling company can thus contribute initial findings on the improved recyclability of flexible packaging applications.

„For Siegwerk Recycling-orientated design This is an important way to close loops for flexible packaging solutions - ideally from product to product. For us, this means offering innovative printing ink and coating solutions that support high-quality recyclates - for example, through simple decolourisation while retaining full functionality in the use phase,“ says Alina Marm, Head of Circular Economy Hub at Siegwerk.

Printing inks play a key role in the production of plastic packaging. They are is decisive for the appearance and functionality of the packaging. They are also one of the key challenges when it comes to recycling packaging waste.

„One of the aims of a high-quality recycling process is to maximise Transparent plastic recyclate that is suitable for reuse in packaging. Successful decolourisation therefore plays a key role,“ explains Klaus Wohnig, CEO of APK AG.

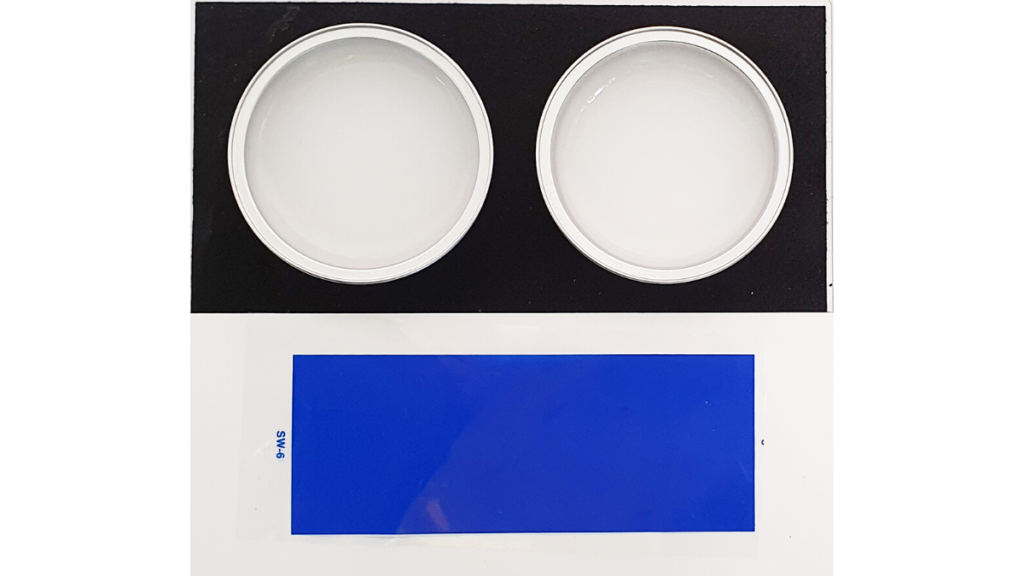

In spring 2020, the research and development department of APK AG tested a range of LDPE film samples, which were double-printed with Siegwerk inks in the colours yellow, red, black and blue. The aim of the series of tests was to clarify whether Siegwerk inks with a solvent-based recycling process such as the Newcycling technology of APK AG can be removed from the polymer matrix.

The film samples were treated with APK AG's solvent and dissolved. The resulting polymer solution still contained printing ink components, which could then be separated in a filter unit specially designed for the decolourisation application with very high separation efficiency. A The decolouration tests of the red, blue and black printed films showed a transparency value almost similar to that of new goods. was achieved. Only the sample based on the yellow printed film still showed a marginal yellow tint.

„We consider the entire packaging life cycle from design to production and recycling. We are therefore delighted that printing inks from Siegwerk clearly Suitable for solvent-based recycling and thus a much-discussed challenge for the recycling of flexible packaging has been mastered,“ explains Ralf Leineweber, Head of Global Technology Development at Siegwerk.

„In the spirit of the EU Green Deal and the new Circular Economy Action Plan With its Newcycling technology, APK aims to close loops for flexible packaging that was previously considered ‚non-recyclable‘. In doing so, we want to fully utilise the reduced environmental impact of recycling without compromising on the quality of the recyclate,“ explains Hagen Hanel, Head of the Plastics Recycling Innovation Centre at APK AG.

In a first step, Newcycling involves the pre-processing of plastic waste, which is also used in conventional mechanical recycling. However, APK then adds a solvent-based step, which removes additives from the polymer - as in the case of Siegwerk printing ink - and generates recyclate similar to virgin material. The polymer is In contrast to chemical recycling, however, it is not broken down into individual components. The molecular chain, and therefore the energy invested in the polymerisation, is preserved.

In addition, Newcycling recyclates (rPE, rPA) have the following properties with 47 to 88 per cent fewer emissions (ifeu, Heidelberg, 2018) have a significantly more positive carbon footprint as new goods.

[infotext icon]Siegwerk, a family business in its sixth generation, is one of the leading international manufacturers of printing inks and individual solutions for packaging, labels and catalogues. With more than 180 years of experience, the company has in-depth knowledge and experience in many printing processes. A global manufacturing and service network ensures that customers receive consistently high-quality products and services. Siegwerk employs around 5,000 people worldwide in more than 30 national subsidiaries and is headquartered in Siegburg near Cologne.APK was founded in 2008 with the aim of obtaining recycled plastic with the highest possible degree of purity from plastic waste. The properties of the recyclate should be comparable to those of virgin plastics. With the Newcycling process, APK's researchers and engineers have developed an efficient recycling technology that combines mechanical and solvent-based steps. APK currently employs around 130 people at its Merseburg site. The production plant has an annual recycling capacity of up to 20,000 tonnes. The established plastic recyclates from Merseburg are marketed under the names Mersalen and Mersamid[/infotext].

Source: Siegwerk