Fast delivery times and cost savings in the area of picking and packing are decisive for competitiveness in distribution centres. Two flexible sorters from Trapo now ensure that goods can be picked according to customer and order specifications.

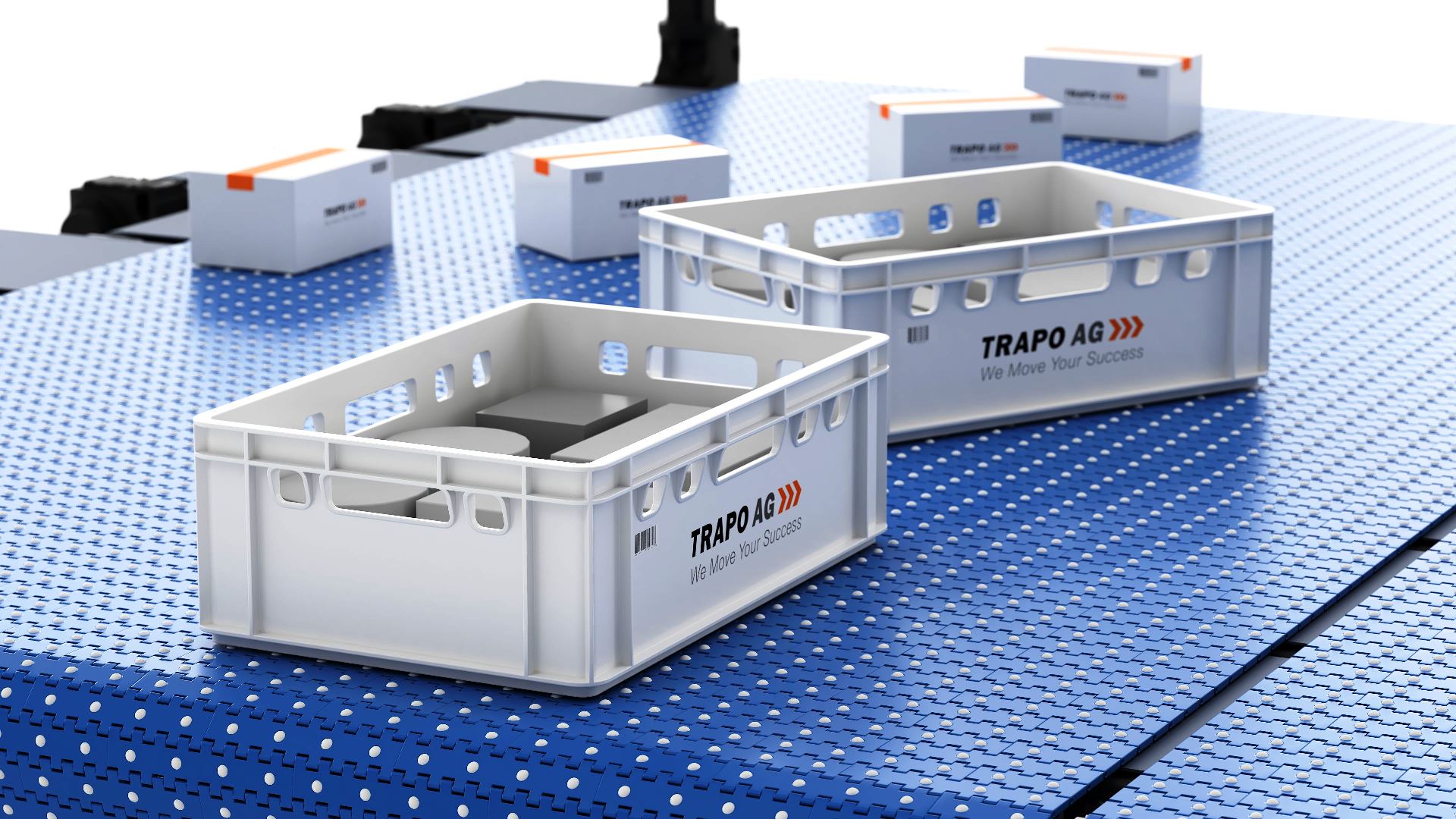

Sorters play a crucial role in controlling and diverting flows of goods. With the TRAPO Omni Sorter and the TRAPO Sphere Sorter, TRAPO AG, a specialist in industrial automation, offers both Two flexible solutions, which can be used to maintain supply chains without disruption even in challenging times.

In a globalised world in which producers and end consumers are often separated by continents and time zones, the Logistics plays a decisive role. Only with a well-functioning distribution is it possible that complex transport chains with various (intermediate) stations seamlessly interlock with each other. Any incorrect allocation of the goods to be transported leads to a Disruption in the material flow and has a negative impact on competitiveness and the company's success.

Control complex flows of goods

Decisive for the Goods allocation are so-called sorters. Their use is always advantageous when the product units originating from one or more sources need to be distributed to one or more destinations.

Sorters show the goods the right way in the distribution centres, ensure an uninterrupted material flow and thus assume a connecting function in the distribution chain. logistical process chain. With their help, goods can be separated according to orders, sorted, brought together and finally assigned to the correct destination.

Areas of application include, for example Incoming goods, unloading lorries or containers for onward transport of products to the warehouse, the Picking area for batch picking and the Outgoing goods when putting together tours and loading the lorries.

Completion of the overall line

With the Omni Sorter and the Sphere Sorter, TRAPO AG offers two sorter systems that are designed for a trouble-free material flow ensure a smooth flow. During transport, the goods can be transferred to and discharged from various transport rails using rotating conveyor rollers. This is how the Omni Sorter as a connecting element between individual conveyor lines and at the same time complements the overall system expertise of TRAPO AG.

Thanks to the modular design the sorter can also be adapted to different on-site conditions and therefore has flexible and multiple configuration options within the given production areas. The result is optimum utilisation of space and smooth onward transport of the goods.

Flexible and space-saving sorter solution

The Sphere Sorter ensures a Precise forwarding, The system can be used to transport, rotate, distribute and discharge packages of various sizes, such as boxes, parcels and letters. It can transport the goods flexibly and at a speed of up to one metre per seconde can be rotated and distributed to several outlets. The sorter can be realised in any width and length and also requires a comparatively small area as it combines several functions.

Source: TRAPO