When it comes to feeding, positioning, dispensing, counting and separating paper and flat products, Kraus Maschinenbau GmbH from Spaichingen offers the right solution for the task at hand. The specialists have now developed a machine combination in close collaboration with developers at the University of Jena that packages the successfully tested coronavirus antibody test.

With the company's systems and components for feeding and separating systems, individual sheets of paper, labels, brochures, booklets, folding boxes, ISO cards (e.g. customer and value cards) as well as plastic products, product samples and sachets can be Up to 30 millimetres thick handle. When it comes to the packaging process itself, it is cardboard and folding carton blanks that are separated and prepared for further finishing steps (counting, printing, embossing, checking). through to security coding can be prepared. All Kraus machines and systems stand for reliability and a Simple and safe operation.

Standard and customised solutions

Potential customers often find an economical and reliable solution for the respective application even with standard devices. When it comes to complex requirements and new problems, the task is analysed and discussed in the project meeting and designed for the greatest possible customer benefit during implementation.

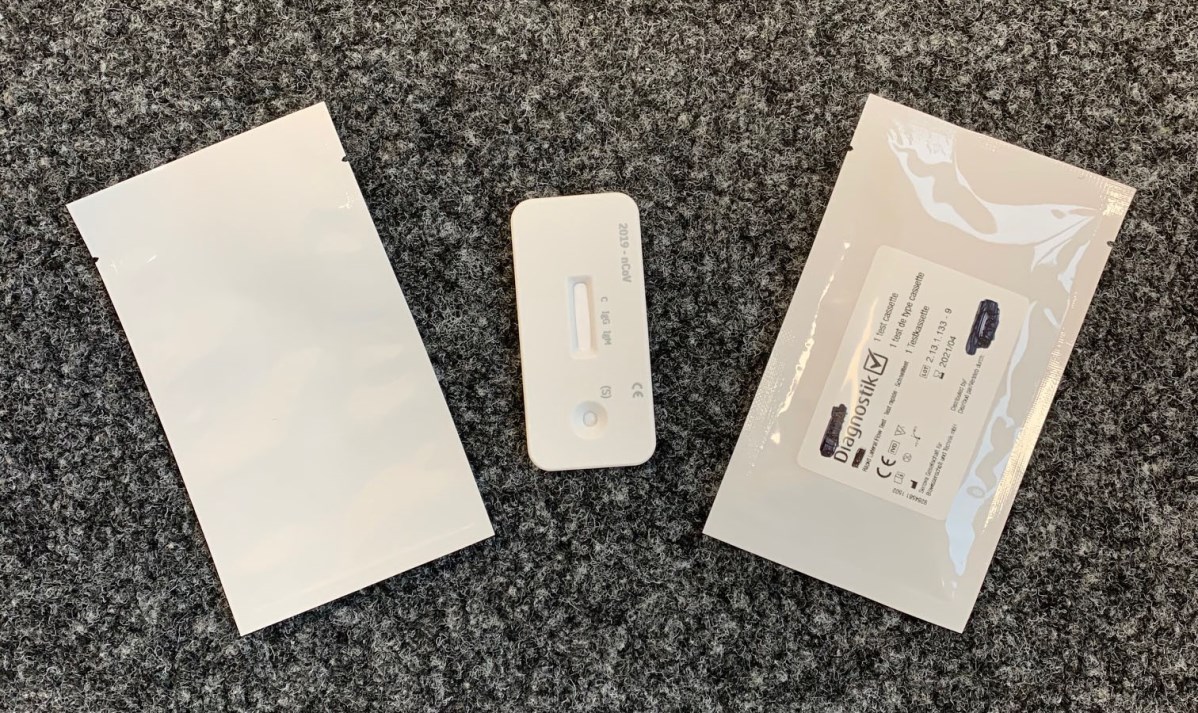

Two machines have now been combined and specified within a very short space of time in such a way that only corresponding Test strips for the so-called antibody test cut, prepared and then Packed together with a test cassette in a plastic bag become.

Interview with Joachim Kraus

To find out more about the highly topical project, which is currently nearing completion, we spoke to Joachim Kraus, the Managing Director of Kraus Maschinenbau GmbH.

pj: Mr Kraus, in addition to your standard machines and components, you also develop and build customised clothing for the special needs and requirements of the market. The best example is the Machine for separating and packaging the new corona test kits. Wow did this project get off the ground?

Joachim Kraus: Our customer, Senova, was looking for a solution for feeding the packaging pouches. Together with the customer, a Overall concept for feeding and packaging the test cassettes for the rapid antibody test, which was an immediate hit. The current situation requires rapid delivery. The schedule we agreed on before we were awarded the contract for a machine to pack test cassettes was correspondingly tight.

At the Design Review The machine's cutting of the test strips to exact dimensions, the transfer of the cut-off piece and the insertion of the cut-off piece into the test cassette offered further potential for collaboration. With a size of between 3.5 and five millimetres, handling the blanks proved to be a challenge. According to the motto: „There's no such thing as impossible!“: The product will therefore not only be packaged by a machine from Kraus Maschinenbau, but also by a machine from Kraus Maschinenbau. also the preliminary product produced on one of our applications.

pj: How do the machines work?

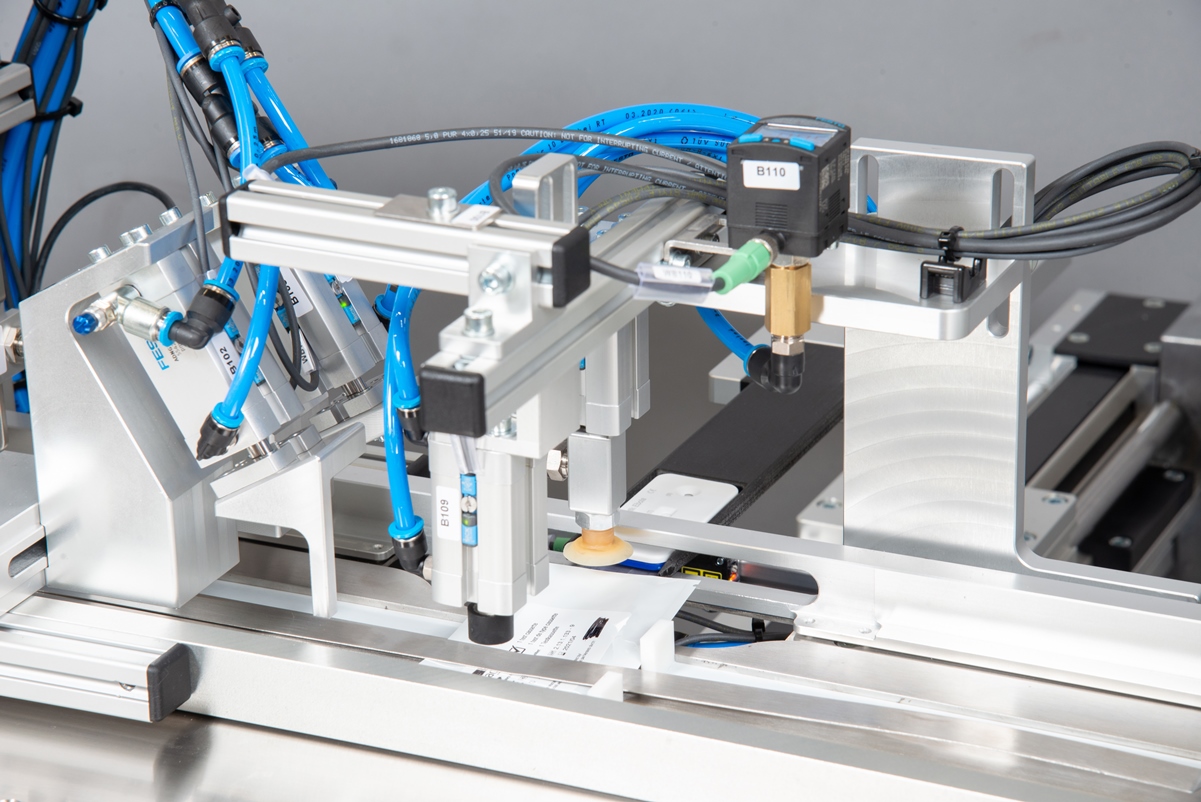

Joachim Kraus: The pre-products for manufacturing the test strips are fed onto the line by our JoKer friction feeder. The approximately 500 millimetre long blanks of the starting material are Process-safe singulated, positioned and then stored in a servo linear unit. The cutting dimension for various types of Covid-19 tests can be defined via the HMI on the machine. The product is positioned under the cutting blade by means of an exact feed and the strip is cut to size. Precisely cut.

A Sophisticated takeover system positions the section for transfer by a robot. The robot then inserts the blank into the test cassette. Further process steps are carried out at the customer's premises to turn the precursors cut by the Kraus application into the functional rapid antibody test.

The machine for packaging the rapid antibody tests then takes over the test cassettes. The pre-assembled bags are separated by a JoKer and dispensed into the packaging machine. In the throughput Labels with the product-relevant data and applied to the pouch, which is then opened and positioned using vacuum suction cups.

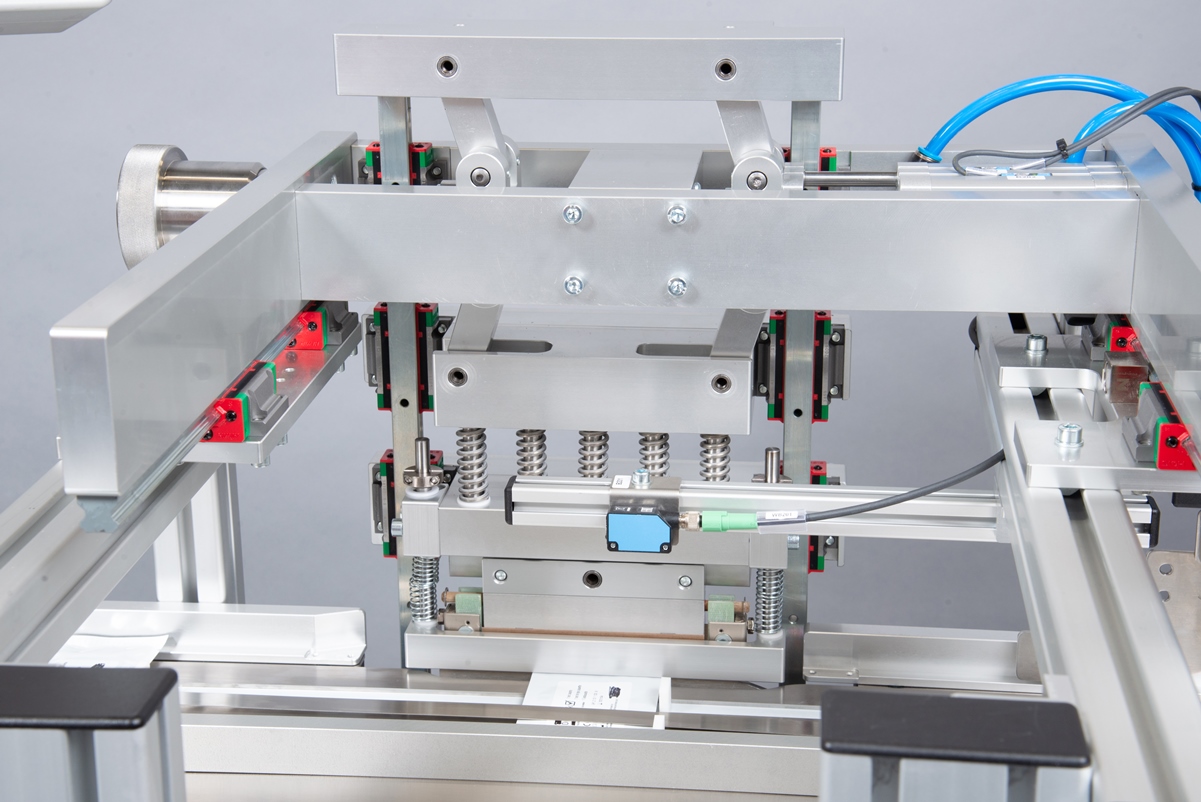

A robot takes the test cassette from the pre-machine and transfers it to a plastic mould. This is inserted into the pouch. The complexity of the plastic mould meant that a 3D printing process had to be used. At the last station of the packaging machine, the bag is sealed by thermal welding.

pj: How many tests can be packed per minute/hour?

Joachim Kraus: The machine provides 30 packages per minute from. This cycle results from the link with the pre-machine and the transfer to the robot. In the area of bag feeding, we have already installed applications with our JoKer friction feeder, with which up to 300 cycles per minute can be realised. Which performance is possible/necessary always depends on the customer specifications.

Short decision-making processes were required

pj: How long did the development and customisation take?

Joachim Kraus: The first discussions with the customer took place in mid-March. The path from conceptualisation to the customer's order was characterised by a long process. tight schedule and high project requirements characterised.

We submitted the offer on 18 March, which was then commissioned on 23 March. In a three-week tour de force succeeded in developing the system. Two teams of developers worked on the project in shifts and coordinated the individual steps with the customer.

To save time, the company did not wait until everything was developed. As soon as an assembly had been designed, the purchasing department became active with the procurement. This does not correspond to our usual way of working, as the Risk, of ordering the wrong components is high. I don't think I'm going too far when I say that a Social interest in the Corona rapid tests is why it is right to take this risk.

Interlocking, communication and cooperation between design, purchasing and assembly not only shortened the delivery date, but also presented a High quality for sure. It is clear that rapid coronavirus tests are urgently needed.

[infotext icon] Scientists in Jena have developed an innovative Rapid antibody test for the coronavirus has been developed. According to the Leibniz Institute of Photonic Technology in Jena, the test uses a blood sample to show within ten minutes whether the test subject is still infected with the virus or is already immune to it (or has not yet come into contact with the virus, editor's note).pj: Which work steps were particularly challenging?

Joachim Kraus: The challenges usually lie in integrating our machines into the overall production line. We have to adhere to the customer's specifications for the interfaces. The coordination with Mr Söffing, the Managing Director of Senova, was very professional and uncomplicated, and the necessary decisions were made in record time.

Special components are used for the thermal welding of the composite material. We had to find a high-performance partner for this. ROPEX was able to supply us with a customised system in a very short time. The reference to the rapid corona test ensured the highest level of commitment from our project partners. In our collaboration with Senova, we also had to take into account that the entire production in the clean room takes place.

pj: When will the first machine go into operation?

Joachim Kraus: The first machine was as early as mid-May delivered. Beforehand, the details and safety precautions in corona times for the visit of our technicians had to be agreed with the customer.

pj: What happens next?

Joachim Kraus: As you can imagine, demand for the tests is currently enormous, meaning that production capacity is unable to meet current demand. Therefore Further lines in planning, and talks are about to be finalised. We are pleased and also a little proud that we are able to make a small contribution to overcoming the situation in these difficult times. Short decision-making processes at Kraus made it possible to Deviation from the usual processes in order to accelerate the customer's delivery capability.