The new ComCut 76 from the Dresden-based machine manufacturer for efficient further processing should pay for itself quickly.

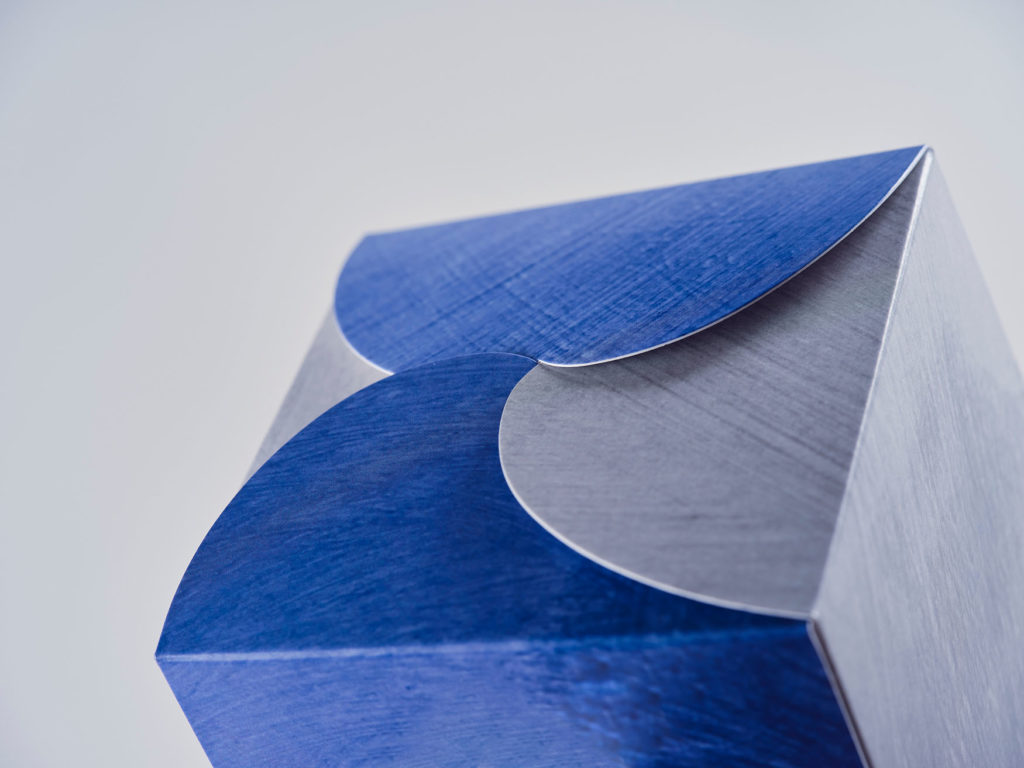

This solution fits in with the times: manufacturer Kama is launching a new punching and embossing machine on the market that is designed as an economical replacement investment for long-serving platens and cylinders. The ComCut 76 offers professional functionality at an entry-level price - with all relevant applications and twice to three times the productivity of a cylinder.

Multiple speed

The ComCut 76 is based on the proven platform of the globally used Kama ProCut and is manufactured with Kama components at the Dresden site. With a sheet format of 760 x 600, the new model is suitable for today's printing presses and processes paper, microwave, cardboard and plastic with a punching force of 165 tonnes and an output of up to 5,500 sheets per hour.

The ComCut 76 offers all applications - die-cutting, creasing, embossing and punching - in consistent output quality and makes further processing faster and more efficient with short set-up times and simple operation. All in all, a modern flatbed die-cutter with contemporary safety that even young operators enjoy working on. This also solves the increasingly difficult search for spare parts and skilled operators for the cylinder. Existing punching tools can continue to be used.

You can count on this machine!

According to Kama, the ComCut 76 pays for itself from just five operating hours per week - even compared to the cylinder, which has long since been written off.

„Many print shops are looking for a solid successor solution for their cylinder that can be refinanced within a reasonable period of time. We offer this solution with the ComCut 76, which fulfils all die-cutting and embossing tasks according to the motto ’reduced to the max’.” Stefan Kleditzsch, Sales Manager for Germany, Austria and Scandinavia at Kama.

The Saxon manufacturer offers an attractive financing model for the machine.

Growth in the portfolio

In addition to the high-quality results, another advantage is faster stripping thanks to fewer nicks. This is worthwhile for the variety of jobs in commercial printing as well as for use in folding carton production. Repeat jobs run on the ComCut 76 with centre-line and 4+1 system after a short set-up time; the die-cutting of stickers is also set up quickly. In contrast to the cylinder, blind embossing is also possible as high-low embossing.

Like all of the manufacturer's machines, the new ComCut 76 is robustly built and, with its „Made in Germany” label, stands for durability and a high resale value. http://www.kama.info

Source: KAMA