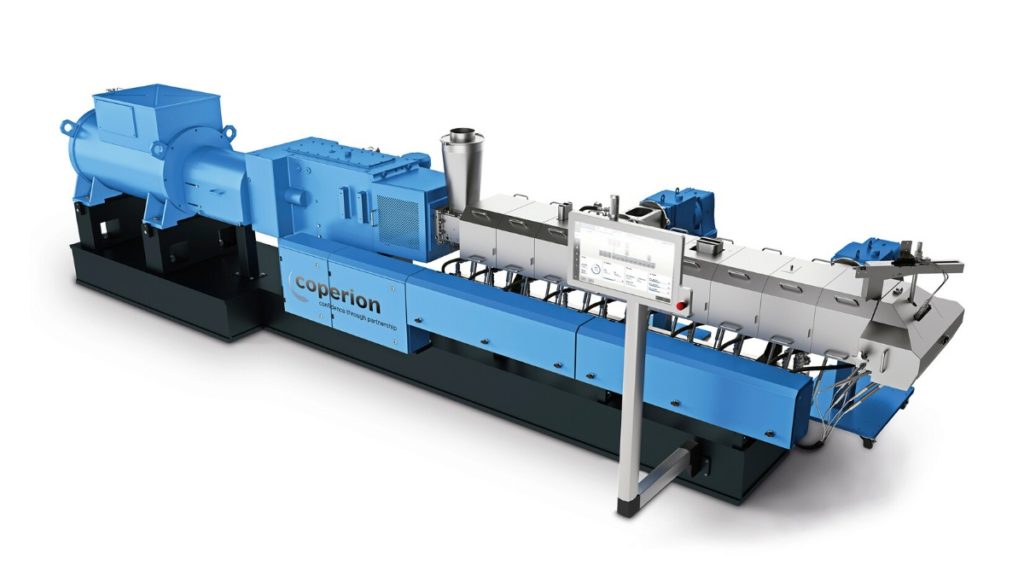

APK AG now relies on ZSK extruder technology and Coperion's process engineering expertise for its solvent-based plastics recycling process Newcycling.

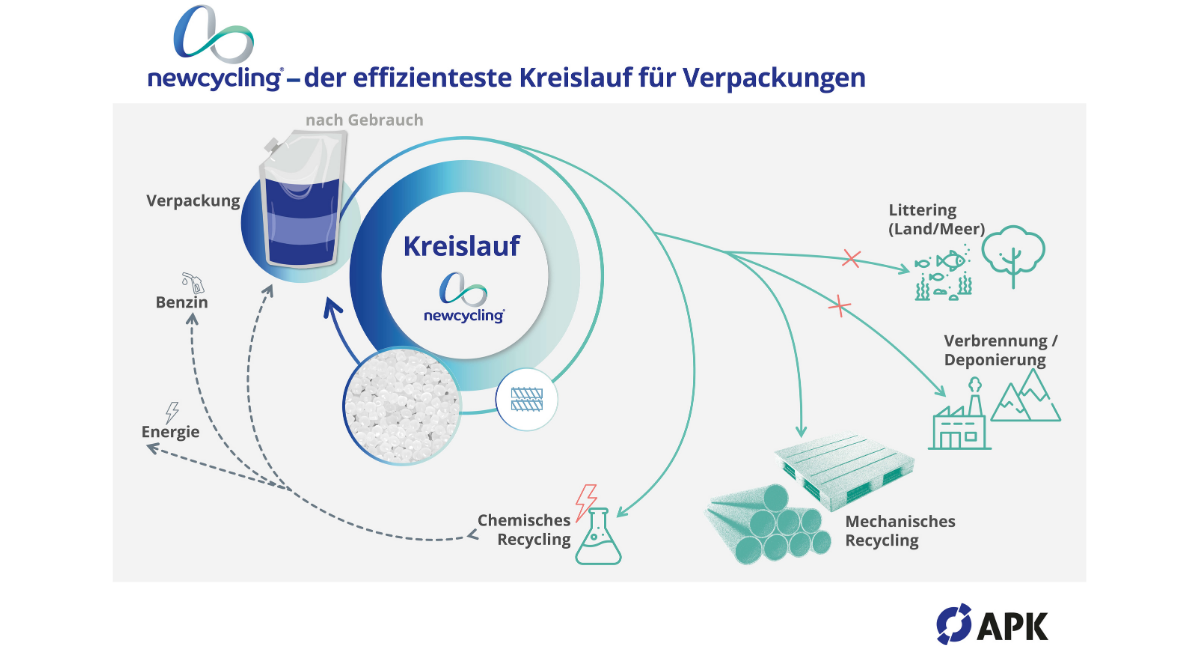

The Newcycling process can be used, for example, to separate various polymers from multi-layer plastic packaging that was previously considered non-recyclable. Using ZSK twin-screw extruders, the processing is to pure re-granulates possible. Compared to chemical recycling, the plastic remains intact and does not have to be re-polymerised, which is energy-intensive and costly. The process is therefore highly efficient both economically and ecologically.

With the physical, solvent-based process, clean and pure PA and PE pellets of almost virgin material character can be obtained from complex polyamide/polyethylene (PA/PE) multilayer film waste. These Recycled materials can be used in high-quality products right back to their original application. Downcycling can therefore be reduced and closed-loop recycling is possible.

And this is how Newcycling works

At the APK site in Merseburg, PA/PE multi-layer film waste is first mechanically pre-treated: Among other things, it is shredded and classified. It is then dissolved in a solvent bath and thus Liquefaction of the PE layer, which leads to separation of the polymers or the polymer layers. The undissolved PA is then separated from dissolved PE using conventional solid-liquid separation technologies and the polymers are further processed in separate material streams.

The PA is fed into a Coperion ZSK twin-screw extruder. There, it passes through various processing zones and is processed into a high-quality PA melt with a very high dispersion rate and intensive degassing. then granulated into first-class PA recyclates.

After pre-evaporation, the PE is also fed into a ZSK twin-screw extruder together with the solvent. This is where the intensive degassing of the liquid takes place, which is precisely tailored to this application and delivers first-class results even with fluctuating ratios of PE and solvent. The solvent is completely volatilised and returned to Newcycling in a closed circuit.®-process. What remains is PE in the form of a homogeneous, high-quality melt, which is then granulated. The PE recyclate also has a quality similar to virgin material.

Significant reduction in emissions

The PE recyclate produced using APK's Newcycling technology is marketed under the brand name Mersalen. The PA recyclate is available under the brand name Mersamid. Both are characterised by their high product quality in combination with a considerable reduction in emissions. Newcycling recyclates have on average 66 per cent less emissions than new goods of the respective plastics.

[infotext icon] Coperion (http://www.coperion.com) is the global market and technology leader in extrusion and compounding systems, dosing systems, bulk solids systems and services. The specialist develops, realises and supports systems, machines and components for the plastics, chemical, pharmaceutical, food and minerals industries. The company employs 2,500 people worldwide in its three divisions Polymer, Equipment & Systems and Service as well as its 30 sales and service companies. Coperion K-Tron is part of the Equipment & Systems Division.„Several expert reports confirm the very high degree of purity of our recyclates. For example, Mersalen is suitable for a wide range of applications such as cosmetics packaging.“

Klaus Wohnig, CEO of APK„We see APK's innovative Newcycling process as a very important step on the way to a circular economy in the plastics industry. Thanks to the use of first-class technologies and the comprehensive process expertise of APK and Coperion, we produce recyclates of very high quality. At the same time, the process saves energy and resources, as it replaces the costly production of new plastics.“

Jochen Burger, Process Engineer at Coperion

The APK was founded in 2008 with the aim of obtaining plastic recyclate with the highest possible degree of purity from plastic waste. The properties of the recyclate should be comparable to those of virgin plastics. The researchers and engineers at APK have achieved this with the Newcycling®process, APK has developed an efficient recycling technology that combines mechanical and solvent-based steps. APK currently employs around 130 people at its Merseburg site. The production plant has an annual recycling capacity of up to 20,000 tonnes. Further information can be found at here. [/infotext]

Source: APK