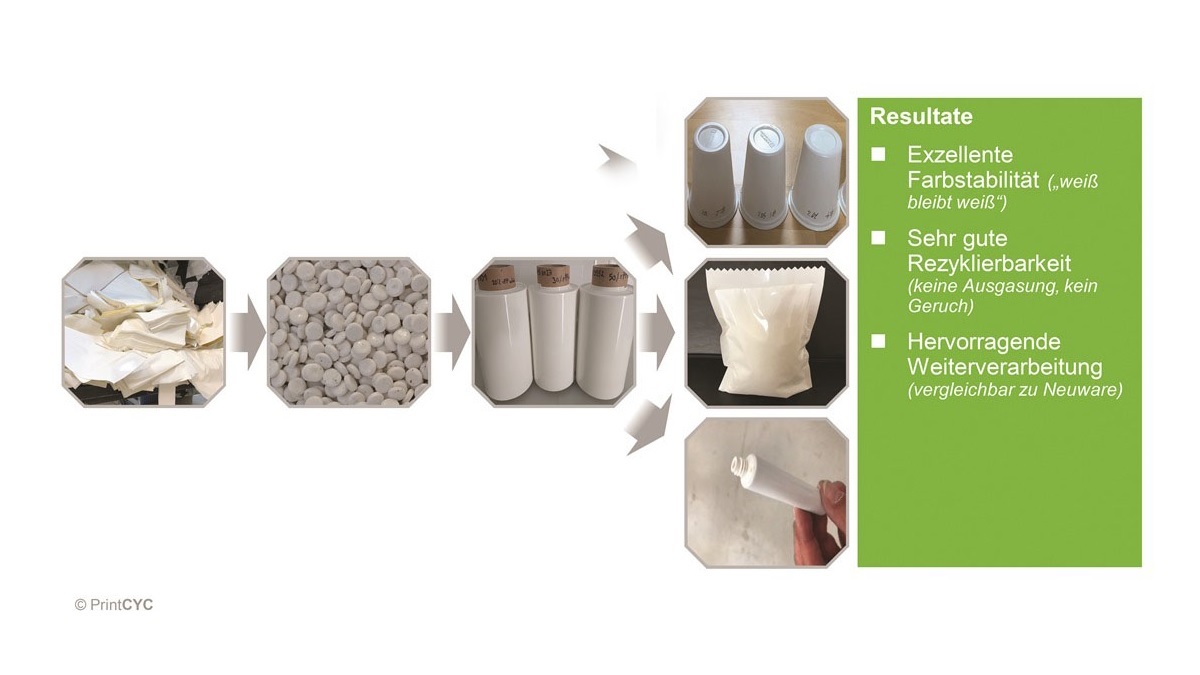

The PrintCYC project initiative has investigated the use of reused recyclates. Various packaging formats were produced using rPP and rPE recyclates. The project results are optimistic.

PrintCYC is an initiative along the value chain for the recycling of printed films with members from a wide range of industries. The aim of the initiative is to develop and test new recyclable solutions. This is based on post-industrial waste and with a view to measurable cost efficiency. According to its own information, the project group has now been able to Recycling of printed plastic films and the Further processing of recyclates from printed plastic films achieved remarkable results. However, deinking technology was not considered in this project.

PP films and packaging samples were successfully produced in an initial project phase with a recycled content of over 50 per cent.

The starting material was biaxially orientated PP film (BOPP), which was printed with nitrocellulose (NC)-based ink. However, the recyclate quality left much to be desired in terms of colour, odour and processability.

Improvement through PU-based colour system

To improve the initial results, alternative ink formulations were tested for printing on BOPP and low-density polyethylene (LDPE) films. In this second phase, a switch was made to a polyurethane (PU)-based ink system in flexographic printing. This led to significant improvements in the mechanical recycling process on a production line that is typically used in practice to reprocess printed film waste.

Due to the high temperature resistance of the printing inks (temperature above 240 °C), no volatile by-products, odour or speck formation were observed. Under these conditions High-quality recyclates with colour-stable properties are produced. According to the company, an initial assessment of the environmental impact revealed lower greenhouse gas emissions and lower energy consumption in the mechanical recycling of LDPE films compared to the production of virgin material.

The new recyclates showed excellent processability for the production of blown films, cast films and even biaxially oriented films that were 100 per cent comparable to virgin material. Up to 100 per cent recyclate was successfully used in the inner layer of a three-layer ABA film structure.

Various packaging formats tested

As part of the second project phase, PrintCYC analysed and evaluated the effects of reused recyclates on various packaging formats. Under Use of rPP and rPE recyclates bags, trays, yoghurt pots and tubes were produced that met the requirements in terms of sealing behaviour, deep drawing and compression deformation.

The PrintCYC members are currently presenting the results of the project. Not least because the EU plastics strategy aims to increase the proportion of recycled material in plastic packaging. The aim of the initiative is to achieve a further to initiate a professional exchange and gain further partners. This is how the project is to be driven forward. The next project steps are to be defined in the coming weeks.

[infotext icon]The PrintCYC project initiative was founded in March 2019. PrintCYC stands for the design optimisation of printed PP and PE films for mechanical recycling. Current members of the initiative are

-

-

- the machine suppliers Brückner Maschinenbau, Kiefel and PackSys Global

- Profol, specialist for flat films made of PP (polypropylene)

- Printing ink manufacturer hubergroup Print Solutions,

- Constantia Flexibles, manufacturer of flexible packaging

- and the recycling technology specialist Erema.

-

Annett Kaeding-Koppers, an independent consultant for packaging and sustainability projects, is responsible for coordinating the initiative[/infotext].

Source: PrintCYC Initiative