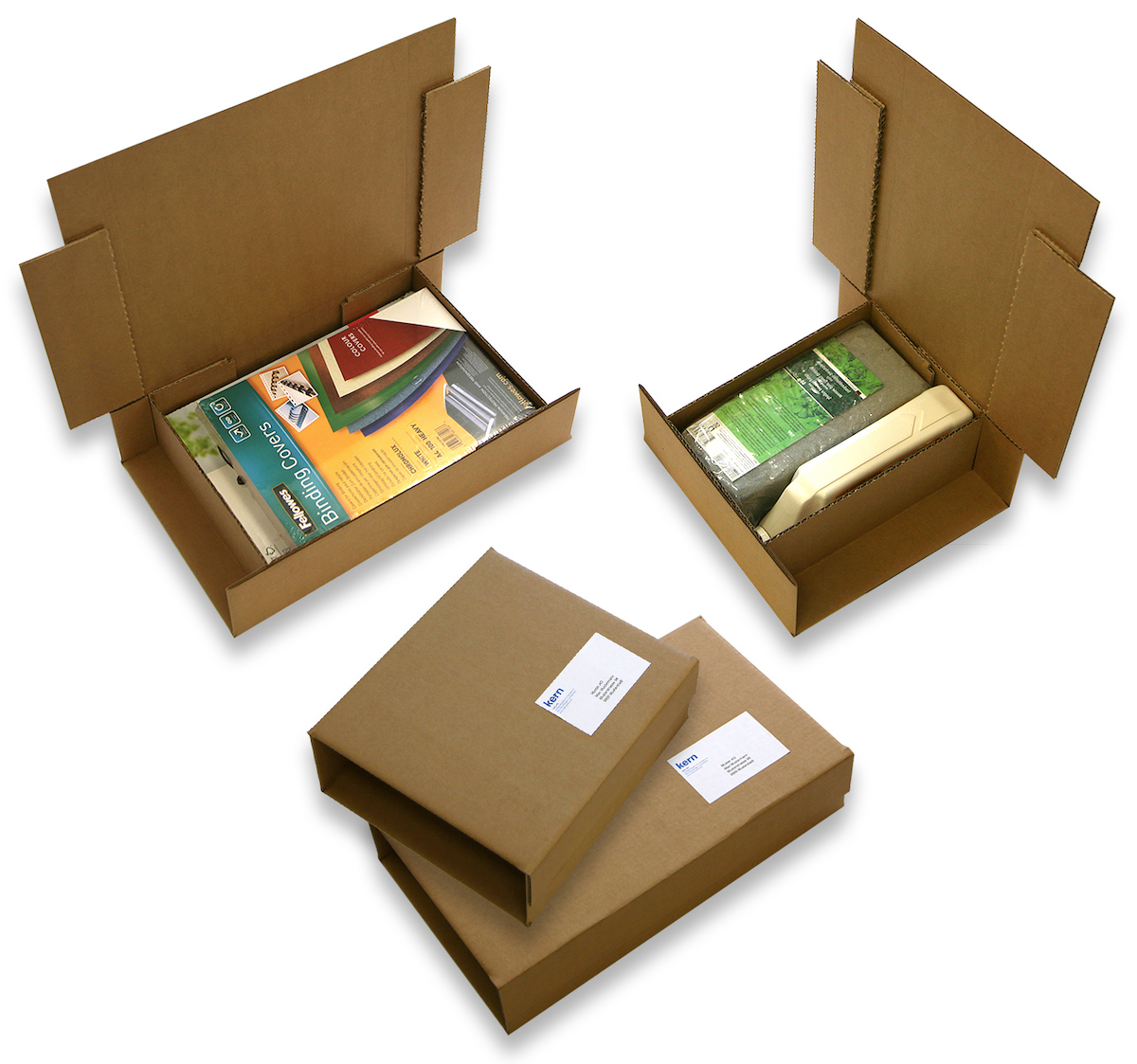

The new PackOnTime 2box multi-format packaging system from Kern produces the packaging on-demand and with a perfect fit. Filling material is therefore no longer required.

Conserving resources is the order of the day. The booming online trade with its usually high volume of packaging material is particularly challenged, to find answers to the packaging waste that arises. With PackOnTime 2box, Kern wants to offer a solution that avoids unnecessary filling material. It ensures the smooth dispatch of a wide variety of items: The packaging is produced on-demand and custom-fit, making filling material superfluous.

The Dutch online printing company Reclameland has recently started using a PackOnTime 2box system. This has allowed the print shop to speed up its production process by 300 per cent. Previously, up to 2000 orders per day were processed; now up to 6000 orders can be packed daily.

With this ecological and economical step, Reclameland is focussing on sustainability and efficiency: PackOnTime 2box cuts the corrugated cardboard sheet to the required size. The cut sheets are then erected, glued and transported to the insertion station. In the next step, the items are inserted and at the end of the process, the system automatically glues the packaging and places the shipping labels. The result is packaging that is customised precisely to the dimensions of the items to be shipped.

PackOnTime 2box optimises shipping logistics

The Dutch print shop was founded in 2008 and has been number two on the market since 2015. Reclameland produces all of its print products in-house. „With the investment in the PackOnTime 2box the company optimises and automates its shipping logistics and thus meets customer expectations for speed, because with this packaging solution the goods“ journey is optimised in terms of time right from the start," says Kern GmbH Managing Director Rainer Rindfleisch.

[infotext icon]Reclameland is the only Dutch online print shop with its own production site in Westerbroek, Groningen. The print shop is currently being expanded with a new hall, which is scheduled to go into operation at the beginning of 2021. Printed matter can then be produced on an area of around 35,000 m².The Kern Group develops, produces and distributes products, solutions and services worldwide in the fields of inserting systems, packaging and logistics solutions. The company has been family-owned since it was founded by Marc Kern and is now managed by second-generation owner Uli Kern. The group is present in around 60 countries worldwide and employs approx. 720 people[/infotext].

Source: Kern Group