Sanner GmbH, manufacturer of pharmaceutical primary packaging and medical technology products, is investing in the expansion of its in-house tool and mould making facilities. The aim is to ensure fast delivery of desiccant closures and packaging for food supplements, especially during the pandemic.

However, investments in the development and realisation of new products are also worthwhile and will be systematically continued in 2021. The coronavirus pandemic has turned production at the company upside down: in particular The DASG 1 desiccant closure recorded a 30 per cent increase in demand. A short delivery time is particularly important for such standard products.

„In order to guarantee this delivery time even at high capacity utilisation, we decided a few years ago to continuously expand our own tool technology. This allows us to react much faster and more efficiently to changing customer enquiries, especially in times of Covid-19.“ Dr Johannis Willem van Vliet, Managing Director of the Sanner Group

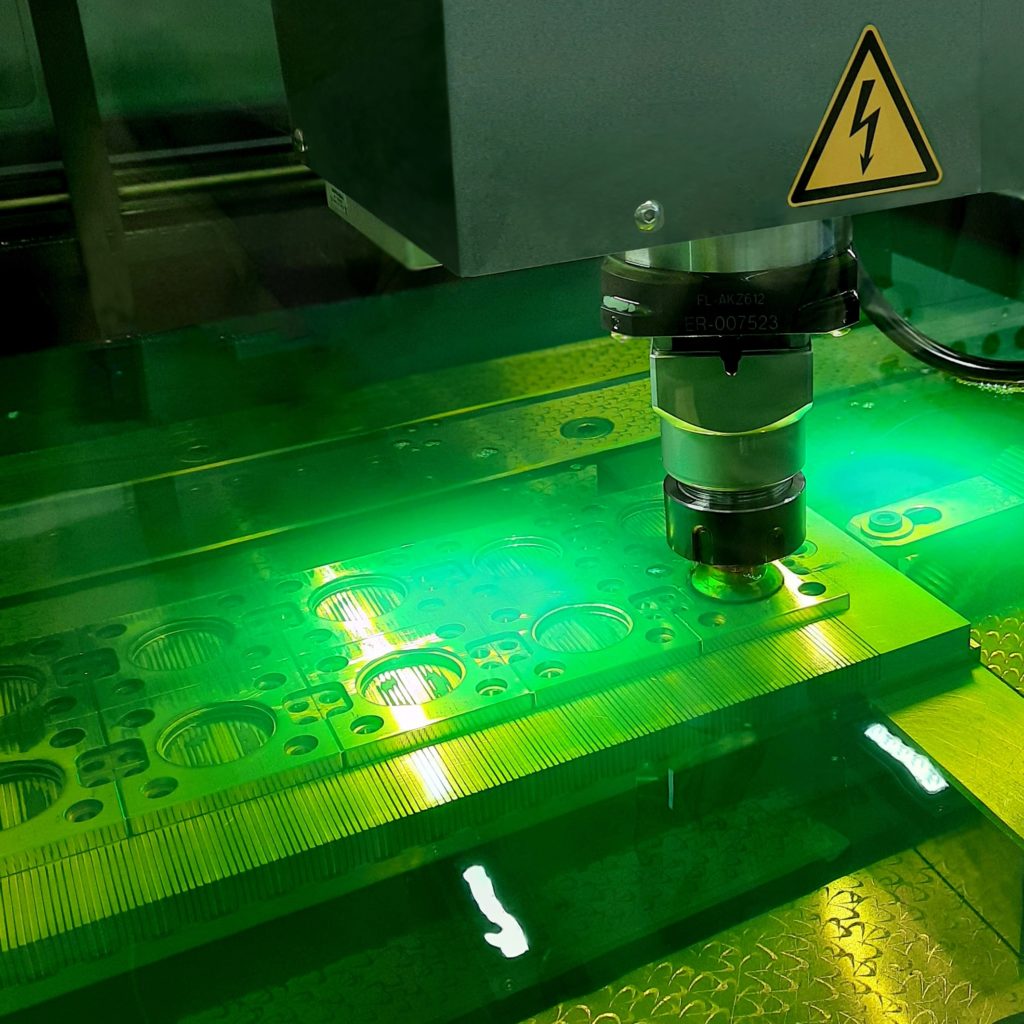

Even apart from the pandemic and the increase in incoming orders, the physical and technical proximity to production stands for Sanner in the foreground. Over the past five years, the company has Around two million euros invested in tool technology invested. In 2020, for example, a new eroding machine was purchased to produce sharp and precise internal contours, as well as a surface grinding machine for the final finishing of the tool inserts.

With three new injection moulding machines, the 2020 Significant expansion of production and capacities in the area of food supplement packaging. Thanks to its well-equipped in-house mould shop, the company is able to quickly and easily produce its own moulds with multi-stage cavity structures for these and other machines that will follow in the first half of 2021 due to increased demand.

Tool technology supports the market launch of Sanner BioBase

Our in-house tool technology essentially comprises tool processing technologies, which are not only important for existing products. They also offer efficient ways of analysing and methodically developing new materials and technologies. For example, tool technology has supported the Sanner experts in the Market launch of Sanner BioBase, the first effervescent tablet packaging made from bio-based material.

Source: Sanner