Syntegon Technology organises two virtual events and presents new packaging solutions for bars and crackers to customers.

In order to stay in touch with customers even during the pandemic, the company is organising Syntegon will be holding two virtual events at its Swiss site in Beringen from 25 February to 3 March. On the one hand, the focus will be on innovative packaging systems around bar production. On the other hand, the company demonstrates its expertise in the safe and reliable Handling of crackers.

„However, we don't just want to show our customers what we have to offer in terms of future-proof solutions, we also want to promote dialogue,“ explains Bruno Oberle, Head of the Horizontal Packaging Systems Product Group. The online event concept therefore includes Live machine demonstrations and expert discussions on trending topics in the food industry - including sustainability, flexibility and hygienic design. „In small, exclusive event rounds, customers have the opportunity to ask their questions, describe their needs and challenges and discuss them with our experts.“

Live from the shop floor to the (home) office

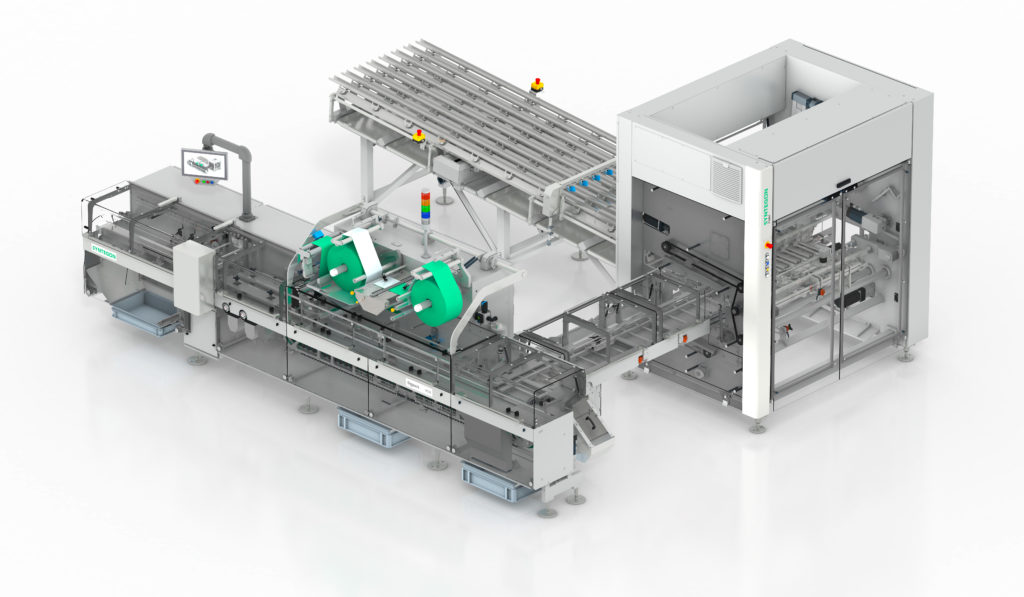

On 25 and 26 February, the exclusive Chocolate & Bar Show. A system is shown for Primary and secondary packaging of bars. After the bars have been moulded, dried and cut, the new Sigpack DCIE discharge station gently across and distributes the bars on the packaging branch.

The first step is a 3D quality check to remove products with poor quality from the packaging process. The FIT product infeed then transports the bars thanks to intelligent linear motor technology reliably and efficiently.

The solution has already been successfully implemented 100 times on the market. In the Sigpack HRM flow-wrapping machine, the bars are packaged with the help of the paper-ON-form module cold-sealed in paper. The first-packed bars are then transported via the New PFI feeder into the correct position and are fed into the integrated Sigpack TTM2 topload cartoner.

Reliable packaging for biscuits and crackers

The Cookie & Cracker Show on 2 and 3 March presents a Flexible high-speed system for reliable handling and packaging of crackers. The solution impresses with its particularly gentle handling and hygienic design - all on a small footprint. Thanks to the flexible configuration, different shapes can also be optimally processed on one line. The crackers are grouped at speeds of Up to 400 slugs per minute.

The HCS flow-wrapping machine with fully automated, new AHS heat-sealing technology enables longer sealing times, which ensure tighter packaging and therefore a longer shelf life for the products. Customers have the option of switching between monolayer and multilayer films.

The system can also be switched from short to long slugs within ten minutes, ensuring maximum flexibility.

Virtual exchange on trends

Syntegon also uses the virtual event for active dialogue with customers. The focus is on current trends and challenges. „These include, for example, technologies such as Linear drive, 3D inspection and sustainable solutions such as paper or mono-material packaging,“ reports Oberle. „We want to understand our customers and their needs precisely. That's how we started last year, Digital Factory Acceptance Tests which met with a great response. We would like to build on this this year and intensify our global partnerships despite limited travel opportunities.“

Source: Syntegon Technology