A consortium consisting of Carbios, L'Oréal, Nestlé Waters, PepsiCo and Suntory Beverage & Food Europe is now presenting food-grade sample bottles made from enzymatically recycled PET. Construction of a demonstration plant is due to begin in September 2021, before an industrial plant goes into operation in 2025.

The consortium was founded in 2017 by Carbios and L'Oréal and expanded in 2019 to include Nestlé Waters, PepsiCo and Suntory Beverage & Food Europe. Based on the enzymatic PET recycling technology Carbios has successfully produced sample bottles for some of its leading products, including Biotherm, Perrier, Pepsi Max and Orangina.

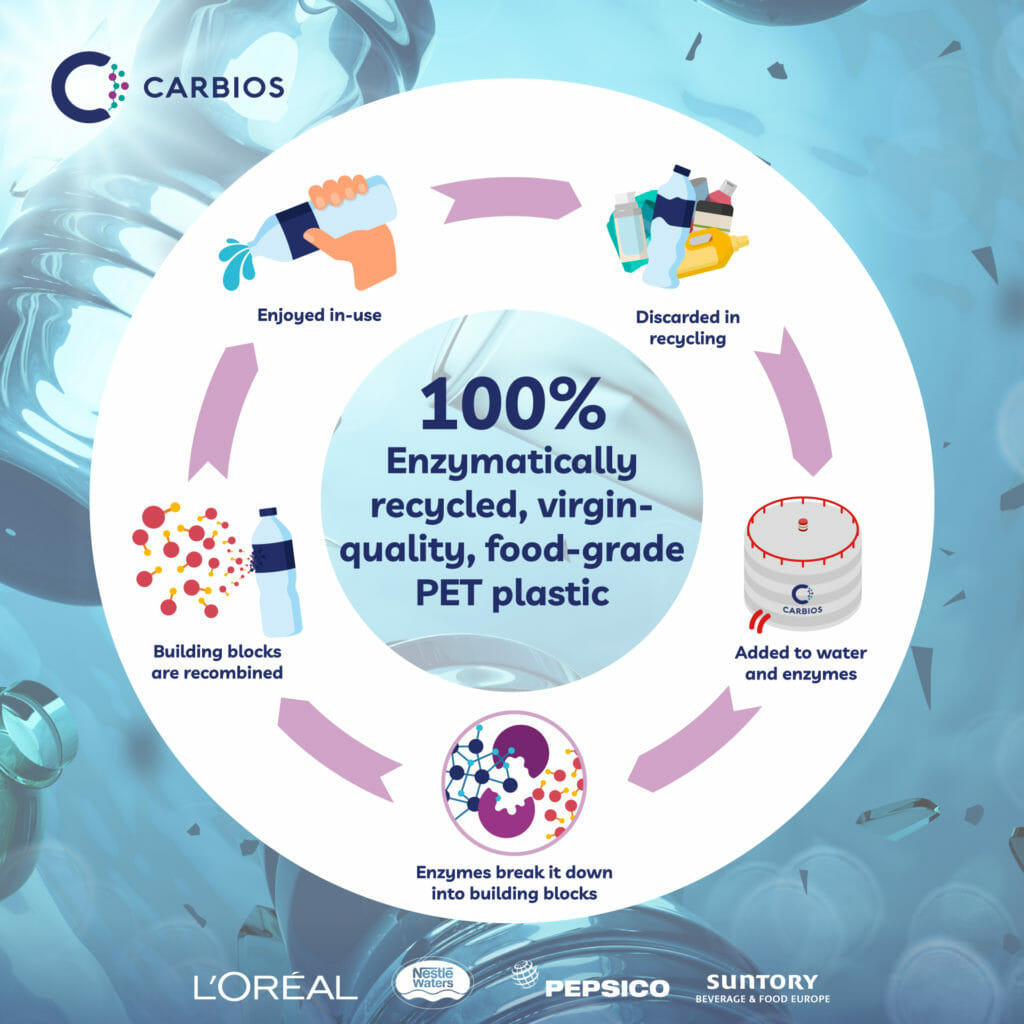

Vision of endlessly recycled PET plastic

After almost 10 years of research and development, the green biotech company Carbios has created a new process that enables a naturally occurring enzyme which normally breaks down the leaf membranes of dead plants. Carbios has refined the technology and optimised the enzyme so that it can break down any type of PET plastic (regardless of colour or complexity) into its building blocks so that they can be turned back into virgin plastic.

Industrial plant planned for 2025

The patented enzymatic PET recycling process from Carbios aims to make it possible to recycle a variety of PET plastics into new, food-grade rPET. The process also runs at high speed 97 per cent of the plastic is broken down in just 16 hours. This method is therefore much more efficient than any previous biological plastic recycling trial.

In the September 2021 Carbios plans to break ground on a demonstration plant before commissioning an industrial plant with a capacity of 40,000 tonnes in 2025.

„With this first, we have created food-grade, transparent bottles from enzymatically recycled coloured and complex plastic with properties identical to virgin PET and, in collaboration with the consortium, demonstrated the viability of the technology with leading global brands. This is a transformative innovation that could finally close the loop on the global supply of PET plastic so that PET plastic never becomes waste.“ Jean Claude Lumaret, CEO of Carbios

Jacques Playe, Global Head of Packaging and Product Development at L'Oréal, adds: „We have been working with Carbios since 2017 to develop this first bottle made from enzymatically recycled PET. This is a Promising innovation for the coming years.“ Jean-Francois Briois, Head of Packaging Material Science and Environmental Sustainability at Nestlé Waters global R&D, explains: „When we reach industrial scale, this enzymatic recycling technology will enable us to produce high-quality rPET bottles and will help Nestlé Waters on our way to becoming the world's leading producer of rPET bottles. Promotion of the circular economy and to reduce the use of virgin plastics.“

Suitable for any type of PET plastic

Enzymatic recycling overcomes the problem of degradation that can occur with conventional recycling and is suitable for any type of PET plastic. As the Carbios recycling process works under gentle conditions, it can be also the CO2-Reduce the footprint of PET waste treatment, by reducing 30 per cent of CO2-emissions compared to a conventional end-of-life mix of incineration and landfill, taking into account the substitution of new PET production.

Carbios wants to licence its technology to PET manufacturers all over the world and thus Global introduction of enzymatic recycling for all types of PET-based products.

Source: Carbios