What does a banker have to do with drives? And what does packaging technology have to do with it today? How do they fit together? Quite simply. A man of numbers is the midwife of a company that today, as SEW-Eurodrive, is one of the international technology leaders in machine and factory automation and is celebrating a milestone birthday this year.

What a start and what material for a historical economic thriller. The year is 1931, we are In the midst of the global economic crisis. Two more years will pass in Germany before the Weimar Republic is history. And during this time, a nucleus for drive technology and automation is created in North Baden. On 13 June 1931, the banker Christian Pähr founds today's SEW-Eurodrive GmbH & Co. KG under the name Süddeutsche Elektromotorenwerke (SEW).

Before that, there was a bankruptcy, The company was Albert Obermoser AG. In 1927, the banker received the order from his employer, Rheinische Creditbank, to audit the accounts of the engine manufacturer in Bruchsal, which had run into difficulties. The engagement ultimately led to the position of interim manager, specifically in the role of commercial director.

The following four years remained exciting and finally ended well with a new beginning. Christian Pähr founded a new company out of the bankruptcy assets of Obermoser AG. The banker had the manufacturing rights in his luggage as an asset for further development.

Christian Pähr did not live to see how well his company would ultimately develop. He died at the age of 70, just four years after founding the company. The women in the family took over. From then on, his widow Kunigunde and their daughter Edeltraut managed the young company.

Strong family cohesion

What followed is very often the case in family-run companies: The generation change was made possible thanks to a close partnership and a wedding. Ernst Blickle, who was born in the Swabian Alb, took over the management of the company from his mother-in-law in 1945. Since then, the company has been inextricably linked with his family name.

The former officer had previously had little contact with his wife Edeltraud's family business. Visionary entrepreneurial spirit and also SEW was fortunate to be largely spared from a devastating air raid on Bruchsal, However, they were to lay the foundations for the flourishing company in the following years. And Ernst Blickle learnt: he acquired engineering expertise at lightning speed. What followed were the years of the economic miracle. SEW grew rapidly. While a black-and-white photograph of the workforce from the founding years shows 35 people, by 1960 there were already 600.

Within just ten years, the drive manufacturer increased its turnover from 1.4 million marks in 1950 to 20 million in 1960. Even then, it was the close geographical proximity to customers with sales territories initially in Germany that enabled the meteoric rise. The establishment of the first foreign branches gave the whole thing further momentum. SEW-Usocome in Haguenau, Alsace, marked the beginning of internationalisation in 1960.

And the technology?

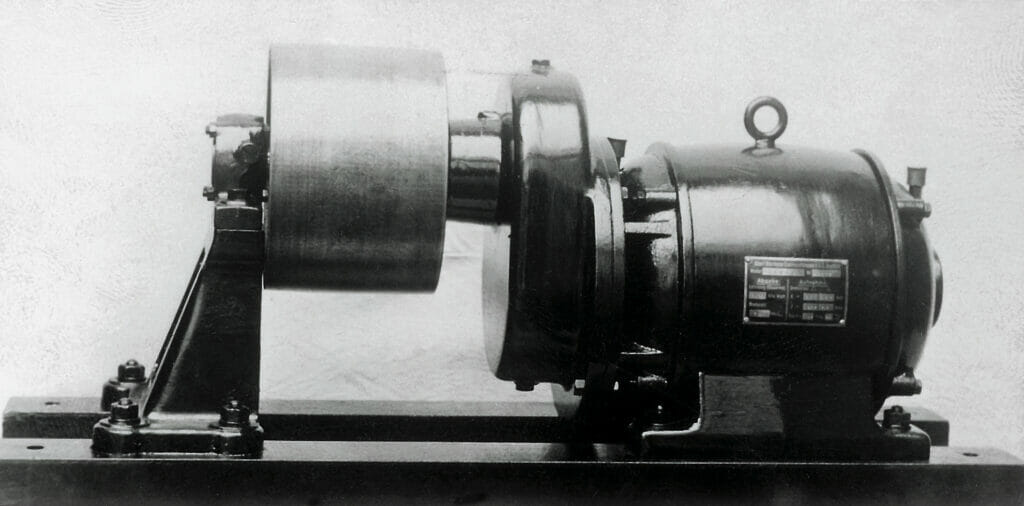

The early years of Süddeutsche Elektromotorenwerke can only be compared to today's drive and automation portfolio to a limited extent. Yes, the first electric and geared motors already existed. In its early days, the company was primarily known for its electric band saws „Milicut“, the „Simplitt“ planer, the „Circut“ electric circular saw and the „Poliglitt“ sanding motors. A production programme that initially reflected Obermoser AG's expertise in woodworking in the pre-war period. However, Ernst Blickle was soon to change this in the direction of an independent modular drive system.

Construction kit in the middle of the 20th century? Yes, that's exactly right. Today's construction kit already existed yesterday, and it was given further impetus in the 1960s with the advent of marketing as a new entrepreneurial mindset. The needs of the market are at the centre of this business management discipline, followed by the consistent orientation of companies towards their customers. But how can the differentiated demands on drive technology be managed economically? How can requirements from different industries and production processes be sensibly fulfilled? At Süddeutsche Elektromotorenwerke during the flower power era, both answers resulted in modular motor-gearbox combinations. An easily and flexibly configurable modular system replaced expensive customised solutions.

Drive as core business

In 1971 it was time to say goodbye to the old name. Süddeutsche Elektromotorenwerke„ became SEW-Eurodrive. Despite all the pride in the company's roots and the loyalty to Bruchsal that still prevails today, the increasing importance of the global market made it essential to operate under a name that also works internationally. SEW-Eurodrive was born; and with two clear messages: „Europe and Drive“ - and „the drive as the core business“.

How did the story continue? For example, with new companies in South and North America and other locations on other continents. Over more than four decades, Ernst Blickle has built his SEW from a small, medium-sized family business into a strong global player. The two sons Rainer († 2021) and Jürgen consistently supported and continued the internationalisation. In 1987, they took over the management after the death of the visionary company patriarch the year before. The success story of the family-run company thus continued.

Paving the way for industrial series production

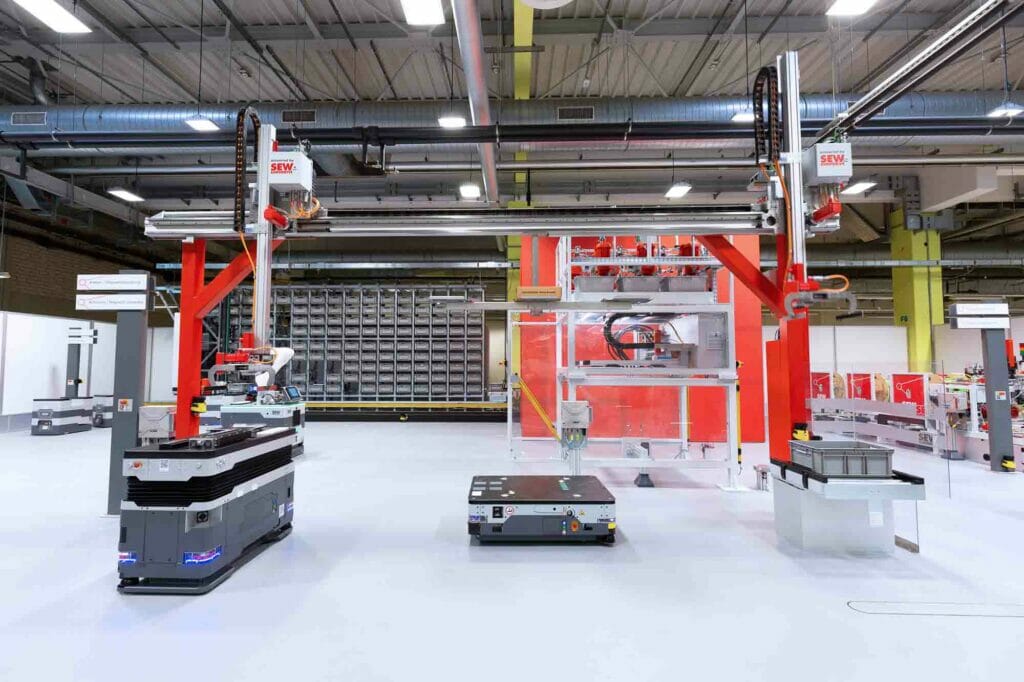

The strategy practised by Ernst Blickle is currently experiencing less of a renaissance with the Maxolution Machine Automation and Maxolution System Solutions business units than the logical further development of the modular system in the direction of modular and optimally prepared solutions for machines, systems or entire factories. It offers enormous advantages for packaging machines, for example, as certain types of machine are particularly prevalent here, which can be operated very well with prepared hardware and software solutions. What exactly is behind this?

Prepared solutions for recurring tasks

In the company's anniversary year, the current situation is once again the question of why packaging technology has important advantages from Maxolution solutions. In this industry in particular, there are processing tasks that are basically the same. The basic features of a flow-wrapping machine remain the same, even if the machines from different manufacturers undoubtedly differ in detail. The vertical or horizontal packaging process itself remains more or less unaffected.

Accordingly, the resulting motion tasks for drive technology also only differ in detail. And this is precisely where SEW comes in, bundling customised and intelligent complete solutions including services in the Maxolution Machine Automation division. The whole thing can be compared to a construction kit from which machines can be designed and built efficiently and quickly. Ultimately, packaging technology in particular is characterised by ever shorter product life cycles and completely new requirements in the direction of batch size 1. short time-to-market determined.

The solutions based on the Movi-C modular automation and drive system are therefore designed with this in mind, Modular machine design. This in turn forms the basis for the „smart factory“, in which machines and systems can be adapted to new challenges comparatively easily by adding or removing process modules. This approach goes so far that the material flow between machines is no longer realised stationary, but with the help of mobile assistance systems. Here, too, the course is set towards flexibilisation. With this approach, SEW is moving away from the classic automation pyramid in favour of a clearly defined solution approach. In addition, Maxolution is representative of the company's claim to be a drive and automation partner for customers with real flexibility. „One-stop shopping“ qualities to be.

And what happens next?

90 years of SEW-Eurodrive this year: Today, more than 19,000 dedicated employees in 52 countries around the world stand behind it. Their motto: „Driving the World“. In view of the challenges posed by climate change in particular, the company believes it is ideally positioned. Storage technology from Bruchsal can already save a lot of energy in production and packaging technology, for example. In view of the increasing digitalisation of industry, the networking of systems will become more important in the future. Urban infrastructure will also take centre stage with, among other things, a dedicated research campus that SEW-Eurodrive has set up together with Karlsruhe University of Applied Sciences.

Further news from the companies

Butterfly takes over ePac Flexible Packaging

CCL Industries expands labelling expertise

Heavy lifting accident in packaging plant leads to heavy fine

Volati takes over Interket Group