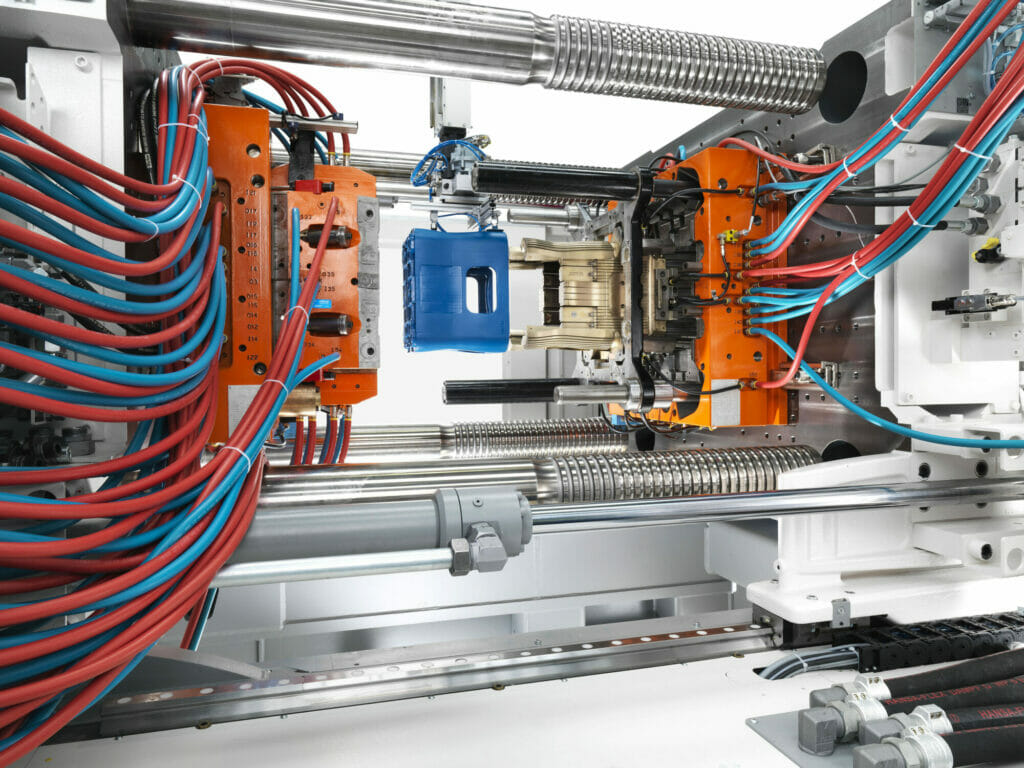

Normally, the gripper waits for a release signal from the injection moulding machine until it moves into the open mould. With KraussMaffei Automation's „synchronised movement“ function, it starts faster, saving valuable cycle time.

Injection, holding pressure, cooling phase - injection moulding is a sequential process and the individual steps are generally optimised. They therefore offer little further potential for cycle time improvement. But what about automation? The time required for the overall process may be shorter, but In most applications, it is the parts removal that provides the leverage to reduce the cycle time.

Time saving due to premature retraction

Normally, the robot only receives the release signal when the mould is completely open. The „Synchronised movement“ function allows the robot to be retracted early. This allows the robot to reach the component removal position during the remaining opening movements. The movements of the mould and handling therefore overlap - saving valuable time.

The goal is, to keep the non-production time as short as possible. This involves synchronising the component removal and the opening movement of the machine. Sometimes this also makes it possible to save on expensive gripper hardware. This is because the ejector movement is often used for parts that are difficult to demould. This means that the robot grips the finished part during the demoulding process and the ejector „pushes“ the part onto the gripper. This requires an expensive pneumatic system for handling („depressurising“).

However, if the gripper moves with the ejector, is also possible without pneumatics. Depending on the complexity of the application, synchronisation can be performed in relation to the clamping, part or ejector movement. The customer thus determines the degree of optimisation.

35 per cent faster removal time

With the synchronised drive, the removal time can be reduced by around 35 percent. In the production of waste bins, for example, this means a reduction in the complete cycle time of six per cent - i.e. a corresponding increase in the total annual volume. For pallets, it can be up to five per cent and for crates up to four per cent more turnover per year.

KraussMaffei offers the synchronised drive both for new machines and in the form of an update for the MC6 machine control system for existing machines and complete systems so that the investment is quickly amortised. Synchronised travel demonstrates its advantages with linear robots from the LRX series and the IR industrial robots from KraussMaffei. The deliberate early start quickly pays off.

Source: KraussMaffei