Labels are an important component of packaging in the pharmaceutical and healthcare industry. They are used on primary packaging such as bottles, blister packs, syringes and vials as well as on secondary packaging such as folding cartons. Depending on the application, they have to fulfil very different requirements - be it resistance to certain external influences, the storage of large amounts of information or protection against tampering. Faller Packaging in Schopfheim is committed to providing its customers with comprehensive support in the selection and processing of labels.

Product labelling, warnings, expiry dates and dosing instructions Doctors, pharmacists and patients can find the most important information about the medication on adhesive labels. In the case of over-the-counter products, they are part of the marketing strategy, increase the appeal at the point of sale and thus boost sales figures. Equipped with batch numbers and serialised codes, they help manufacturers to make their production processes transparent and traceable and to protect themselves against counterfeit products. In order to be optimally equipped for these and many other tasks, we are developing Faller Packaging Labels in a wide range of variants.

Labels - more than just „stickers”

Faller Packaging offers an extensive range of adhesive labels for every conceivable application. Product labelling, for example, completes different primary and secondary packaging with general information. They are also used as labelling labels in retail and logistics. Closure labels, on the other hand, have the task of guaranteeing secure first-opening protection for the products to which they are attached. This protection has been a legal requirement for prescription-only pharmaceutical products in the EU since 2019.

Documentation labels have partial labels that can be easily detached or removed and stuck into a patient file or a vaccination card, for example. They therefore contribute to complete documentation and keep the crucial information at hand. Wrap-around labels are a practical solution for round containers such as bottles or vials, while transfusion, infusion and injection bottles can be hung up directly using hanger labels.

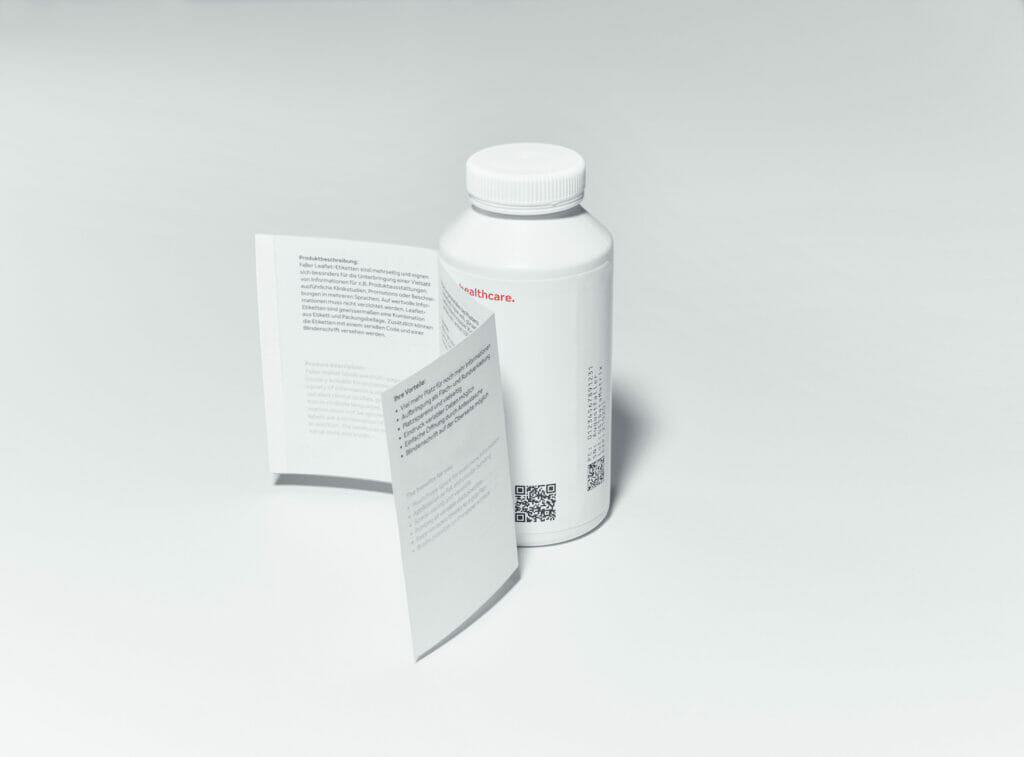

When it comes to accommodating longer texts and large amounts of information, multi-layer labels or multi-page labels are a good choice. Here, Faller Packaging dispenses with the usual film lamination. The Multipage labels are made exclusively from paper and can be recycled without hesitation - They therefore help to make medicine packaging more environmentally friendly. The multipage adhesive labels are available with two to 32 pages and are a combination of label and leaflet. They are available in two versions: as a booklet label in brochure form and as a folded leaflet label.

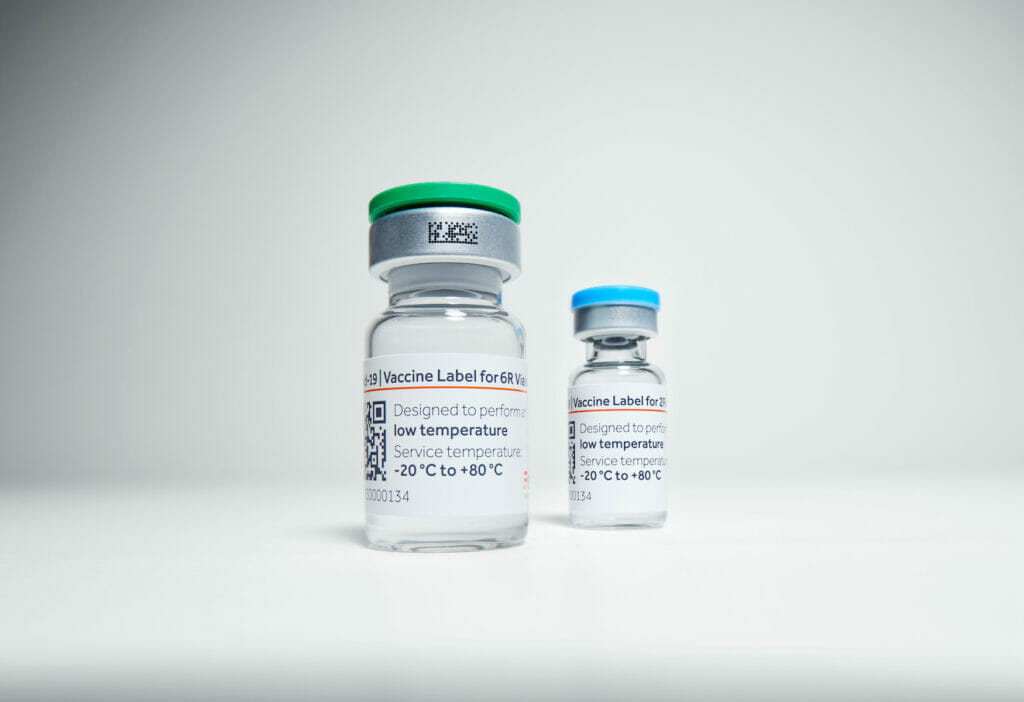

The packaging specialist also has special temperature-resistant labels in its portfolio that are suitable for use at extremely low temperatures. The labels ensure that important information and its legibility on the product are preserved during storage and transport. The outer material and adhesive are designed so that they can also be used in extreme cold (from -196 to 120 degrees Celsius). The labels are therefore ideal for labelling COVID-19 vaccines and aseptic medicines, but also for numerous other applications, for example in cryogenics.

Customers can choose from numerous design options for all products. For example, the labels can be permanently adhesive, Removable or resealable design with perforations, detachable sides and various opening options be equipped. Faller Packaging can also provide them with Braille (Braille for the blind), visible and invisible security features or a serial code in accordance with Directive 2011/62/EU.

Accompanying the customer right from the start

Faller Packaging specialises in secondary packaging and offers folding cartons, leaflets and self-adhesive labels from a single source. The Faller site in Schopfheim in southern Baden is responsible for the development, production and sales of self-adhesive labels. A lot is currently happening there: Faller Packaging is investing in the future and, with a new organisation and new responsibilities, will further intensify its customer orientation towards service in order to grow with the customer.

„Due to the large number of variants, the vertical range of manufacture and the valid requirements of the pharmaceutical industry, adhesive labels are among the most demanding products at Faller Packaging. We are pooling all our expertise in labels in Schopfheim. We are realigning our organisation so that in future respond more individually to each customer We are developing from a supplier to a partner for our customers.“

Matthias Schmieder, Director Business Unit Labels at Faller Packaging in Schopfheim

Together with Tim Santo, Head of Business & Customer Centricity, Schmieder has been responsible for the realignment in Schopfheim since autumn 2021. The magic word here is „customer centricity“. Faller is thus putting the needs and requirements of its customers at the centre and accompanies them along the entire customer journey - from the initial consultation and analysis to storage on the shelf. The Faller experts analyse the customer's needs and specific requirements at an early stage and work with them to develop solutions for existing and future tasks, challenges and processes. „The direct customer benefit is always at the forefront,“ explains Santo. „We therefore follow three principles when it comes to customer support easy business, peace of mind and seamless integration. Our customers can therefore rely on simple business processes and trust that everything will run smoothly and fit easily into existing structures.“ The following example shows what this looks like in practice:

A major pharmaceutical customer is undergoing a global reorganisation within the Group. Due to the market uncertainties and the significantly more dynamic framework conditions - cost structures, pricing, delivery times and regulatory requirements - the forecasts regarding the required quantities are also changing, and with them the planning certainties while customer requirements remain the same and in some cases increase. „This is where our partner concept comes in,“ says Santo. Together with the customer, Faller analyses the changed requirements in close coordination with all departments and specialists, both internal and external. Faller Packaging then adapts the organisation and workflows and optimises interfaces. For example, warehouse logistics and machinery are adapted to the batch sizes and packaging required by the customer. „This enables us to optimised processing steps at the customer's premises, offer them a customised digital supply chain and are perceived as a solution-oriented partner,“ summarises Santo.

The Faultless and trouble-free operation at the customer's premises during the packaging process is also a key aspect of the developments at Faller's Schopfheim site. This applies to standard labels as well as to technically very demanding applications or labels with security features and serialisation.

More news from the magazine

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow

Powerful automation for mills

Decentralised signal processing with the Schmersal Safety Fieldbox