The Austrian packaging industry and brand owners developed the Packaging Technology degree programme together with FH Campus Wien in 2015. Students on the programme also work on real projects. This gives graduates practical training and often the chance to secure a job straight away.

With an annual turnover of over six billion euros and around 14,300 employees, the Austrian packaging industry is an important sector in the Alpine country. With Austria's first academic training programme in the field of packaging technology In the specialist area of packaging and resource management, the aim is to secure and further expand competitiveness.

„Our part-time Bachelor's degree programme in Packaging Technology is the only one of its kind in Austria and interdisciplinary with a focus on sustainability We've built up a strong foundation,“ explains Victoria Krauter, the City of Vienna's endowed professor for sustainable and future-orientated packaging. „What sets us apart: The degree programme is Very practice-orientated due to the cooperation with the packaging industry. It covers all packaging materials relevant to packaging, such as paper, plastic, metal and glass, and thus provides graduates with a good overview.“

For example, the focus is on the question of how to sustainably package challenging filling goods such as food and pharmaceutical products. The students benefit from the Possibilities of the multidisciplinary university in ViennaIf, for example, research is being carried out in the field of cell-based test systems in the molecular biotechnology degree programmes, the packaging technology degree programme ties in with this in order to test packaging for safety.

The degree programme covers the entire life cycle of packaging - from development and production to packaging design, recycling, disposal, marketing and quality management. Places are coveted and limited, Every year, around 30 young people start studying packaging technology.

„The curriculum includes a compulsory internship in a company, where many students often make contacts for their future job.“

Victoria Krauter, endowed professor of the City of Vienna for sustainable and future-orientated packaging

Soft skills are also taught as early as the Bachelor's degree programme, but especially in the subsequent English-language Master's degree programme in Packaging Technology and Sustainability - as Preparation for a management position in the economy.

Challenge with practical relevance

The Bachelor's students should first acquire special competences in the area of sustainability. They receive these in the integrated course „Sustainability and Packaging“, which focuses on the fundamentals, methods of sustainability assessment, sustainable product and process design and the communication of sustainability aspects.

Teamwork and creative thinking are also required when they are confronted with practical problems. Every course includes a Packaging challenge, in which the group is asked to develop real, sustainable packaging in cooperation with a company. At the end, the best solution is presented and awarded a prize.

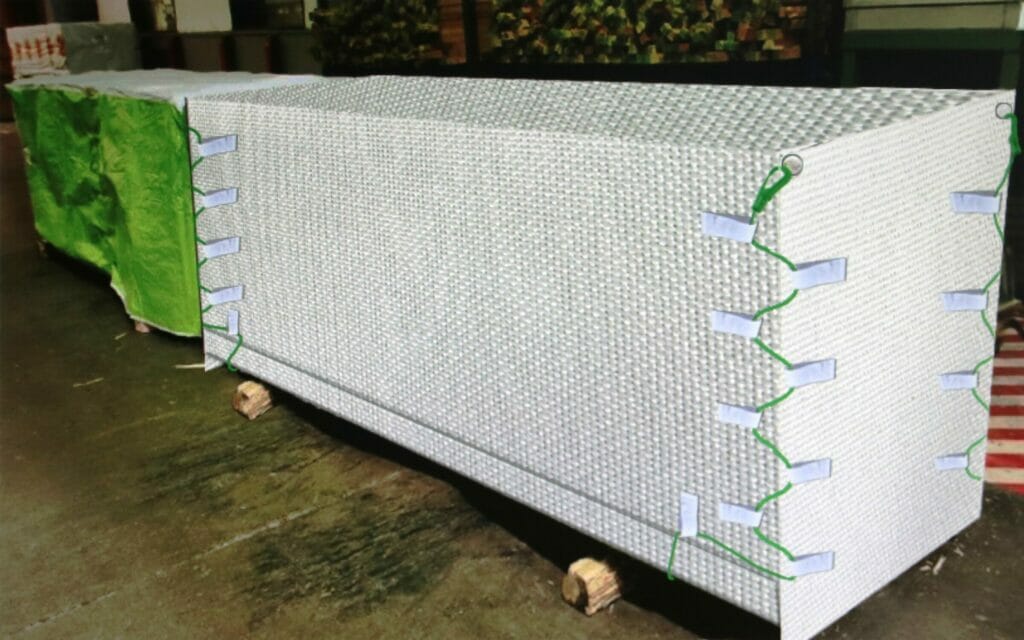

The last semester challenge was organised in collaboration with Stora Enso carried out. Andreas Streit, Manager Sustainability, Environment & Climate at Stora Enso Wood Products in Austria, guided the students. „The task was to, to develop transport packaging for our sawn timber boards. It had to be suitable for outdoor storage, have a sustainable design and be reusable.“

The reusable packaging is to be used in internal process flows, for example, but also by customers who regularly receive material deliveries from Stora Enso and are prepared to return transport packaging. The company's requirements were high: the packaging had to be robust, tear-resistant and easy to fold, offer protection against rain and temporary UV protection, and also Reusable at least five times, recyclable and also be cost-effective.

The participants then had to examine and select various materials, develop a suitable design and research capacities and prices. In the end, there were several proposals from which a project was selected for practical implementation at Stora Enso: a reusable polypropylene bonnet with special colour coding for the required sizes of three and four metres. „In the end, however, it was not a single proposal that prevailed, but approaches from the other works were integrated into Teamwork, so that we ended up with an optimal solution,“ says Victoria Krauter.

Centre for international research

The food technologist is not only very involved in teaching, but also in research. At the FH Campus Wien, she also heads the competence centre for Sustainable and Future Oriented Packaging Solutions. Together with her team, she has developed a guideline for designing recyclable packaging, which is also recommended by the World Packaging Organisation.

The Circular Packaging Design Guideline explains the basics of sustainable packaging design and provides recommendations for the recyclable design of packaging systems for all players along the entire value chain. The guide is continuously updated and Adapted to changes in collection, sorting and recycling technology and to future material developments. Most recently, in October 2021, the legal basis and the level of detail of the design recommendations were adapted and the guideline was expanded to include a country comparison between Austria, Germany and the Netherlands.

Victoria Krauter also heads one of five working groups within the European research project Circul-a-bility, which aims to establish a Europe-wide network on all aspects of food packaging by 2024. The aim is to harmonise and integrate research, exchange information and support the industry in implementing sustainable alternatives.

More news on the topic of sustainability

BDE calls for improvements to the Packaging Act

UBA and ZSVR: packaging recycling works

Poly-clip solution for compostable nets

Tetra Pak invests in barrier technology