Wipak UK is launching a new packaging solution for butter. The recyclable paper packaging can be recycled via the paper waste stream and has a 68 per cent lower carbon footprint compared to standard packaging on the market.

The butter packaging is made from renewable, FSC-certified paper, is Aluminium-free and with modern, thin natural coatings coating. The coating is characterised by its good oxygen and water vapour barrier properties and grease resistance compared to standard paper.

"Most butter wrappers on the UK market are made from greaseproof paper or a grease-resistant paper that is usually made into composite laminates with aluminium and polyethylene. Although they are made from renewable resources, coated parchment papers do not promote the circular economyas they are not easy to recycle. Unlike butter packaging on the market, which is made of complex material structures, our consumer-friendly paper solution is fully recyclable in the kerbside paper and cardboard waste stream after cleaning. Furthermore it retains the look and feel of traditional butter packagingcan be fully printed with brand symbols and can be processed with existing butter packaging machines."

Keith GaterTechnical Development Manager at Wipak UK

The recyclable butter film from Wipak UK has the Shelf life tests successfully passed after packaging on automated packaging lines and was awarded an A+ rating in the recycling tests carried out by the BioComposites Centre at Bangor University. This classification is the highest possible rating that can be achieved for the efficiency of paper recycling. According to Gater, pulp recovery must be at least 98.5 per cent. The Packaging from Wipak UK complies with British guidelines for the recycling of paperwhich stipulate a minimum paper content of 85 per cent, explains the Technical Development Manager.

Focus on sustainability

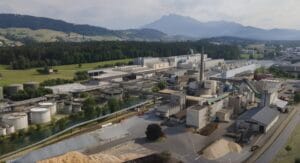

The butter wrap format is one of several new product development projects developed using Wipak UK's combi laminator - part of a recent £5m+ upgrade to the company's fleet of machinery to increase the improve the packaging provider's sustainable product range. This investment will help Wipak UK move closer to its goal of carbon footprint of the company and achieve carbon neutrality by 2025. to reach.

"In view of the growing pressure from consumers brands and retailers need to act decisively and offer sustainable packaging solutions that challenge traditional methods. Solutions such as Wipak UK's butter packaging not only have significant Advantages for the environmentbut also help to ensure that brands remain relevant in an increasingly competitive market."

Keith Gater

Source: Wipak

More news on paper packaging

International Paper divides Group into two units

JH Holding acquires stakes in Akarton and Poprawa

Nextpack replaces polystyrene with honeycomb cardboard

Perlen gets into moulded fibre packaging