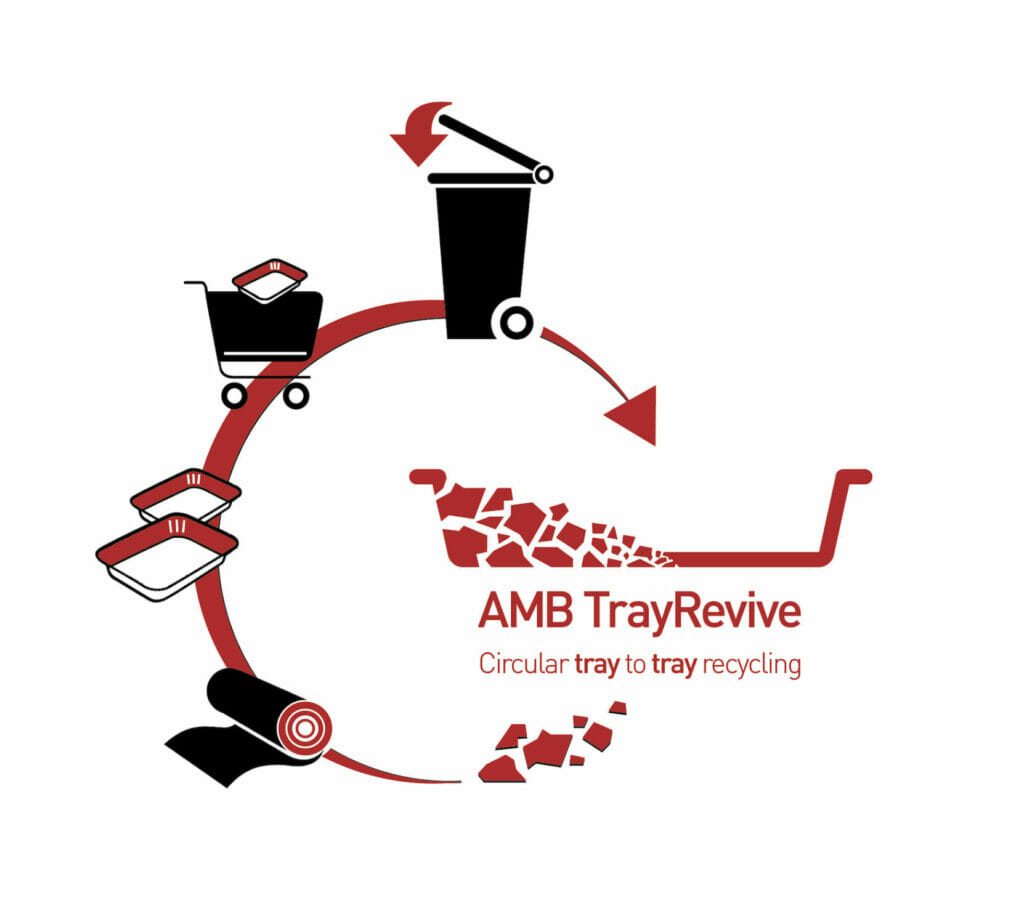

AMB Spa is launching a sustainable use for used food trays. For AMB Tray Revive, the material from used trays is used to produce new trays. The company offers customers an end-to-end process from packaging design to mould making, prototype production and film production.

AMB concluded that the demand for recycled bottles will drive rPET for tray solutions in a different direction. It is expected that the demand from the bottle industry for bottle-to-bottle recycling up to 0.5 million tonnes of rPET needed, which will lead to bottlenecks in the production of recycled tray material. In collaboration with an Italian recycler, AMB has now launched an initiative to collect post-consumer trays in order to minimise the Promote the recyclability of PET trays from the food segment.

High demand for rPET

In order to produce high-quality shells, the raw material comes from 95 per cent from recycled food trays and is subject to a strict analysis procedure. The post-consumer tray material is subjected to a process to counteract contamination. The quality of the flakes is then analysed. AMB examines the material in terms of its behaviour in the extrusion process and its mechanical performance. The resulting New film is extensively checked, so that its appearance and quality as well as its behaviour in the thermoforming process can be evaluated.

With these tests, the company guarantees its customers the high quality of the finished packaging: The Mechanical performance of the material and the thermoforming properties on FFS systems remain unchanged. The material thickness also corresponds to that of standard PET/PE or mono-PET. AMB's Tray Revive concept promotes the recyclability of trays and helps customers to improve their own environmental footprint in order to convince food retailers and consumers, who are increasingly demanding environmentally friendly packaging solutions.

In accordance with the EU action plan, AMB has committed itself to contributing to the EU market for recycled plastics to increase to 10 million tonnes by 2025, by reducing the environmental impact of the products. The tray revive concept is part of a strategy with which the company is further optimising partnership-based cooperation between all AMB stakeholders.

Source: AMB Spa

More news on the topic of recyclate

Emerald Packaging and Walmart cooperate

Recycling industry sounds the alarm - bvse calls for reforms

France honours the use of recyclates in packaging

Circular Packaging 2030 - Strategies against the PCR shortage