Modern production and supply chains, as well as changing consumer behaviour, place high demands on intralogistics. This development does not stop at the food industry. For this reason, the organisers of this year's Anuga FoodTec are focusing on this area.

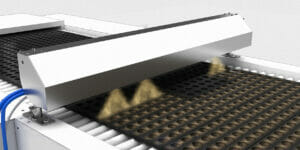

Decentralised logistics systems have been a reality in companies in the food industry for years. Thanks to state-of-the-art software, warehouse management is always informed when a new delivery of raw materials arrives. Fully automated transport management systems transport the raw materials and finished products to their destination as efficiently as possible - to production, order picking or outgoing goods. The focus here is on conveying, sorting, infeed and outfeed as well as buffering and stowing goods.

Intralogistics 4.0

With the vision of self-organising intralogistics 4.0, a number of other technologies have been added in recent years. Driverless transport systems (AGVs) with or without fork lifts are already a familiar sight in warehouses. They connect different areas of the company without barriers, even over long distances. The portfolio of exhibitors at the Anuga FoodTec includes a wide range of innovative solutions for small and large load carriers that guarantee reliable material flows around the clock.

Despite all the digitalisation and robotics, people will continue to perform important tasks in the warehouse in the future. The aim is to plan modern logistics environments in such a way that employees and machines can work and communicate seamlessly with each other. Ergonomics also continues to play an important role in the physically strenuous activities in the warehouse. Digitalisation is opening up new perspectives here.

Specialist programme on the topic

This also includes the use of augmented reality using data glasses, which some providers have already developed to market maturity. The user can concentrate on their task while the glasses transmit all important data such as storage location, article number and number of picks in real time via a display at the edge of the field of vision. At the same time, a pick-by-vision solution like this replaces the handheld scanner, as 1D and 2D barcodes can be easily scanned with the data glasses. All that is needed for wearable computing in the warehouse is WLAN coverage.

The intralogistics specialists will be presenting suitable solutions for all warehouse automation tasks at Anuga FoodTec 2022. The digitalisation of internal material flows remains the No. 1 topic. What are the biggest challenges of the future in intralogistics? When is the right time for food producers to address this topic? And how do you go about implementing the new technologies? Visitors will not only find answers to these questions at the Cologne exhibition centre from 26 to 29 April, but also as part of the specialist programme with its mix of forums, discussions and presentations.

Source: Anuga FoodTec

Further news about Anuga FoodTec

Mondi at Anuga FoodTec for the first time

Wrap pizza and enjoy pizza

Flexible labelling and inspection

Dosing dips and sauces