A new factory is due to go into operation in the summer, where Bio-Lutions' Fibcro natural fibres will be processed into sustainable, fibre-based packaging using PulPac's dry moulded fibre technology.

The German cleantech start-up Bio-Lutions cooperates with dry moulded fibre pioneer PulPac with the aim of replacing single-use plastics worldwide. Together with machine suppliers, they have developed a dry moulded fibre production line, which is scheduled to go into operation in the new Bio-Lutions factory in Schwedt/Oder in summer 2022.

Bio-Lutions mechanically converts agricultural residues into self-binding and long-lasting natural Fibcro fibres. This patented process eliminates the need for binders or chemical cellulose insulation as the whole fibre is used. The start-up wants to use these fibres in conjunction with PulPac's dry moulding technology to produce a variety of sustainable disposable products, such as service food (cutlery and crockery) as well as protein, fruit and vegetable packaging.

The introduction of the new dry moulded fibre technology is intended to facilitate the production of the cost and quality advantages compared to existing cellulose moulding solutions.

Technology saves water and energy

According to the company, the collaboration with PulPac opens the door to a additional production technology for fibre forming, which enables both technological diversification and optimisation of the dry forming processes. The Dry moulded fibre-technology saves significant amounts of water resources and energy, resulting in a carbon footprint that is up to 80 per cent lower than alternatives. The process is fast and more efficient than conventional fibre moulding methods.

„When we are able to form partnerships that prioritise the creation of real solutions for the plastic age, then change becomes possible. That's why we're delighted to be able to add PulPac dry moulding as a second key production process.“

Eduardo Gordillo, CEO of Bio-Lutions.

„The products that will be launched this year will take the concept of sustainable packaging a big step forward. We look forward to a long-term partnership in which we can share our expertise and experience to realise the full potential of dry moulding in Bio-Lutions“ operations and customer network." Linus Larsson, CEO of PulPac AB

Source: PulPac

PulPac - More news

PulPac receives money for fibre packaging

SIG and Optima join PulPac

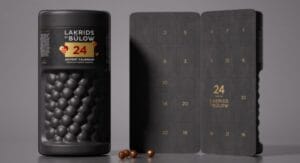

Advent calendar with dry moulded fibre packaging from PulPac

Fibre-based bottle closure