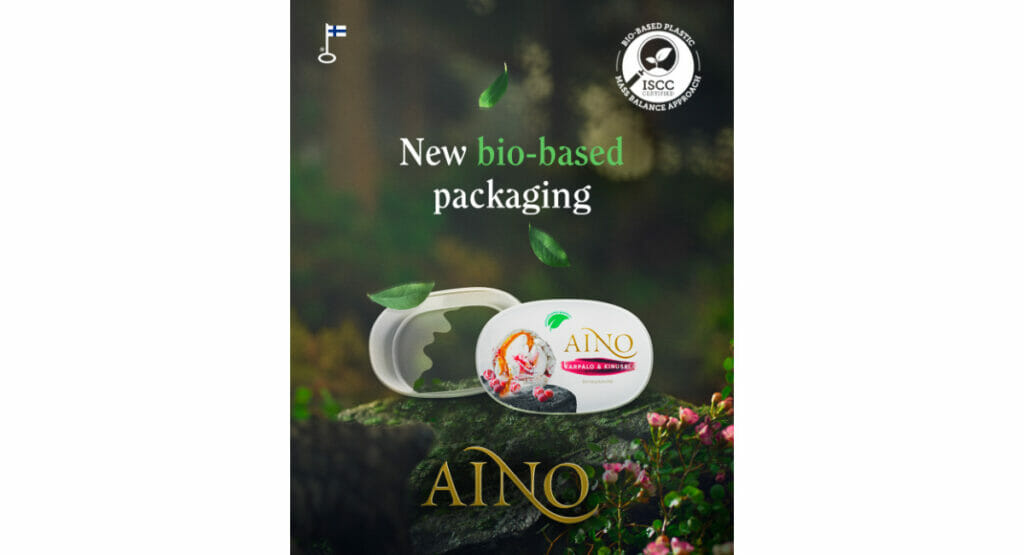

Driving forward the circular economy in the plastics industry - this is the goal of a trio of companies and they have realised it directly with new packaging. Borealis, ice cream manufacturer Froneri and Paccor are now packaging Aino brand ice cream in mono-material packaging made from certified renewable raw materials.

As part of the partnership, the new Aino packaging cups and lids based on renewable bornewables polypropylene (PP) Types of Borealis which is certified on the basis of mass balancing in accordance with the ISCC Plus programme. The collaboration between Borealis, Froneri and Paccor is an example of the development of innovative, responsible applications for the packaging industry, which helps to minimise the Transitioning the plastics industry to a more sustainable and circular economic model to accelerate.

„The new Aino ice cream packaging, which we took from concept to market in just 12 months, is an excellent example of what collaborations can achieve to support the plastics industry on its journey to carbon neutrality. We are very proud of our contribution to the success of this joint project, which once again underlines that our Bornewables polymer portfolio is the perfect material for high-quality, high-performance packaging solutions.“

Peter Voortmans, Global Commercial Director Consumer Products at Borealis

Bornewables PP are made from Biomass, waste and second-generation residues that do not compete with the human food chain. The proportion of renewable raw materials is verified by mass balancing in accordance with ISCC Plus, which enables the material to be traced from production to end use.

In addition, branded companies can increase the certified proportion of renewable raw materials by using raw materials that are already Information applied during production („in-mould“) or by a representative packaging label. Froneri, the first ice cream company to receive the recognised ISCC PLUS certification in this highly sensitive packaging segment, intends to extend the use of Bornewables polymers to other European brands.

„Sustainability is extremely important to us and is at the centre of all our activities at our production site here in Finland. At our ice cream factory in Turenki, we are constantly working on improvements and implementing concrete small and large measures to become even more sustainable - for example by switching to renewable energy, such as electricity from wind power or biogas, or through carbon-neutral heating. In addition, wherever possible, our packaging complies with the FSC (Forest Stewardship Council) standard; the cocoa used in our products is also certified by the Rainforest Alliance - to name just a few examples of our sustainability activities.“

Charlotta Lindberg, Senior Brand Manager at Froneri

In-mould labelling ensures recyclability

The new Aino ice cream packs are produced by Paccor through an integrated process with In-mould labelling injection-moulded from Bornewables PP, making the innovative mono-material packaging 100 percent recyclable is. In addition, the renewable material can be used in the partner companies' existing production and packaging lines without any modifications and with maximum efficiency. At the same time, it helps the companies to improve their ecological footprint.

„By using renewable raw materials, we were able to minimise our CO2-emissions without having to adapt our production process. This is a significant breakthrough and another important step towards reducing our company's dependence on crude oil. In addition, compliance with the ISCC Plus standard ensures complete transparency in production - and therefore the highest quality standards for our ice cream packaging products.“

Andrzej Olszewski, Plant Manager at Paccor Bydgoszcz

For end consumers, this fulfils the Bornewables material fulfils all functional requirements for durable and protective food contact packaging, which are also suitable for deep-freeze applications. At the same time, it meets the ever-increasing demands of consumers, who want packaging products to minimise their impact on the climate and use as little fossil raw materials as possible.

Source: Borealis

More news on food packaging

EFSA has finalised data call

Sustainable packaging in the spotlight at BIOFACH

Canada makes front-of-pack labelling mandatory

Butterfly takes over ePac Flexible Packaging