Industry and brand manufacturers have high hopes for PEF - however, the raw materials used compete with food cultivation. The Dutch company Avantium is working on a way to produce PEF from plant residues. A study by the nova-Institute confirms that the new bio-based polymer has a low CO2 footprint.

What are the benefits of PEF?

Industry and branded goods have high hopes for PEF. Its high barrier properties make it particularly interesting for the food and beverage sector. PEF stands for polyethylene furanoate and is produced from one hundred per cent plant-based raw materials.

The result of the study

The nova-Institute has now carried out a life cycle analysis (LCA) of Avantium's PEF applications, which has been reviewed by independent experts.

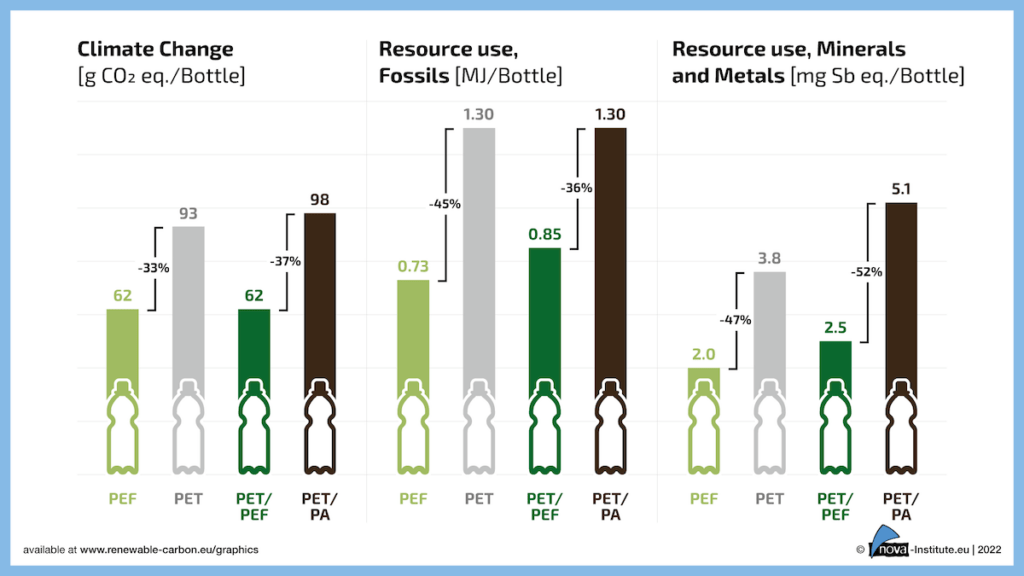

The study shows a significant reduction in greenhouse gas emissions by using 100 % of renewable carbon in PEF instead of fossil carbon in PET for the production of 250 and 500 ml bottles.

PEF has superior properties compared to PET

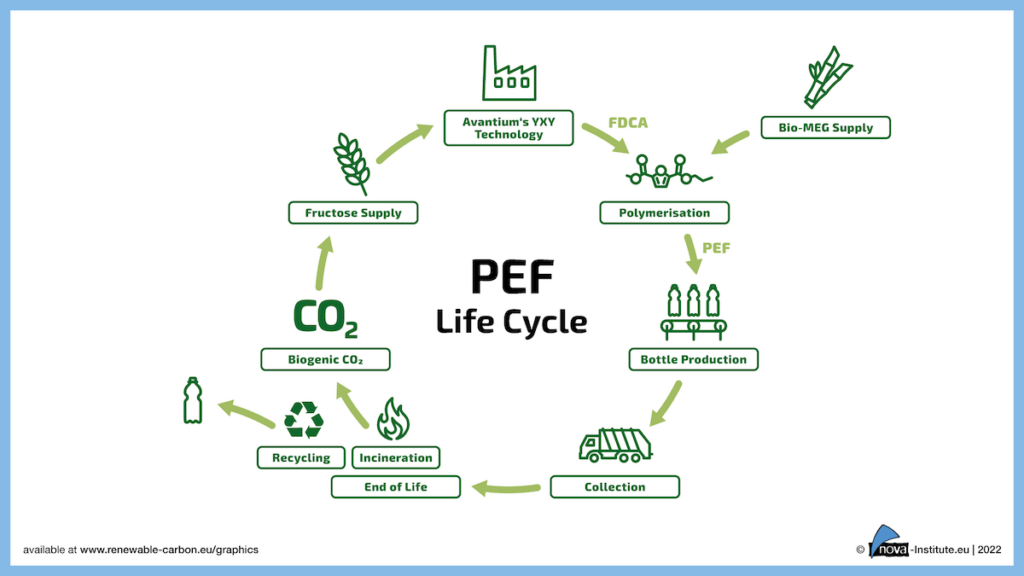

Avantium has developed the so-called YXY technology, which converts plant sugars into a fully recyclable polymer. The main building block of PEF, FDCA (2,5-furandicarboxylic acid), can be produced from sugars (fructose), e.g. from wheat, maize and sugar beet. FDCA is polymerised with plant-based monoethylene glycol (MEG). The result is a 100 % plant-based PEF polymer.

Once the technology is fully developed, PEF can also be produced from cellulose and thus from agricultural and forestry waste streams. Avantium's current process is based on starch from European wheat.

PEF has improved barrier properties compared to PET, it is mechanically and chemically recyclable and can also be recycled as part of the established PET recycling process.

PEF is also suitable for multilayer bottles

In addition to pure PEF bottles, PEF can also be used for multi-layer packaging.

In the LCA, 250 ml multi-layer bottles made of PET and PEF with a PEF content of 10 % were also analysed and compared with PET/PA reference bottles. These had a standard content of 7 % PA (polyamide). The analysis showed that replacing the PA layer with PEF leads to a significant reduction in greenhouse gas emissions of around 37 %, mainly due to the recyclability of the PET/PEF system compared to the non-recyclability of the PA-containing system. This material replacement would also contribute to a significant reduction in the demand for finite resources (-37 % of fossil fuels and -52 % of minerals and metals).

PEF market will continue to commercialise

According to the researchers, the commercialisation and growth of the PEF market is expected to lead to significant economic, technological and ecological optimisations along the entire value chain. The impact of plant-based raw materials could be further reduced by switching to second-generation biomass, for example.

Avantium is currently testing this. An update of the LCA is then planned.

Source: nova Institute

More news Green Packaging

Italy shows organic expertise

Sustainable action plan for beverage packaging

Sustainable packaging in the spotlight at BIOFACH

Nextpack replaces polystyrene with honeycomb cardboard