In October 1947, ATOMA Gesellschaft für automatische Waagen GmbH is entered in the commercial register. The company specialises in the construction and repair of all types of scales. Since Wilhelm Ludwig Krämer founded the company, it has developed into one of the world market leaders after an eventful history. Today, the MULTIPOND brand stands for quality, reliability and innovative, customised solutions worldwide.

The escape from the approaching Soviet army takes Wilhelm Ludwig Krämer, the founding partner of the ATOMA-MULTIPOND Group, moved to Upper Bavaria shortly before the end of the war. Together with his father, who had had to leave his engineering office behind in Berlin, he initially stayed with farmers in the small village of Traunwalchen.

The trained engineer was not yet 30 years old at the time and did not want to remain idle. He decides to set up a company together with a friend who had previously worked as a businessman in the weighing industry. The company is located 70 kilometres east of Munich and 35 kilometres north of Lake Chiemsee. Apart from the forest and a few buildings of a disused explosives factory, there is nothing there. Sudeten Germans who had to leave their homeland at the end of the war later founded the small town of Waldkraiburg there.

Difficult starting times

The company was founded in October 1947 as ATOMA Gesellschaft für automatische Waagen GmbH was founded. Initially, the company made a living from repairing war-damaged scales. The aim is to manufacture automatic indicating scales, hence the company name. The partner soon leaves, and Wilhelm Ludwig Krämer continues to run the company alone. However, due to a lack of raw materials and suppliers, from 1946 to 1950 only Hand-operated running weight scales are manufactured according to the founder's design drawings. To purchase raw materials and semi-finished products, material purchase vouchers must initially be obtained from the Bavarian Ministry of Economic Affairs.

With the currency reform on 21 June 1948, the situation changes abruptly and series production of scales can finally begin. In 1950, the production of automatic pointer scales which are mainly used in industry and commerce, railway stations, post offices and Raiffeisen banks. ATOMA has already made a name for itself, but is still struggling to survive.

A vision becomes reality

In 1962, chance brought about the decisive turning point. In the meantime, so-called supermarkets had also appeared in Germany, offering pre-packed and precisely weighed goods for self-service. The owner of a confectionery company in Waldkraiburg at the time had seen scales from British and American manufacturers at trade fairs that automatically, continuously and at high speed fed a predetermined portion into packaging machines. He approached Wilhelm Ludwig Krämer and encouraged him to develop such a machine. Automatic weighing machines for packing sweets to develop and manufacture scales for him. The prospective customer introduces him to the sales manager of a German manufacturer of flow-wrapping machines, who is very interested in being able to purchase scales from a German company to fulfil his requirements. Feeding the flow-wrapping machine with the exact weight portions. He takes Krämer by the hand and flies with him to Paris to introduce him to the world of packaging machines at the packaging trade fair taking place there. Wilhelm L. Krämer recognises his opportunity, accepts the challenge and - sitting on the edge of his bed with a drawing board in front of him, working through the night - sets about designing one of these filling scales.

The first automatic weighing machine in Europe

In 1963, ATOMA is the first manufacturer on the European continent to exhibit such an automatic weighing machine at the interpack packaging trade fair in Düsseldorf. ATOMA was so successful that from then on the company dedicated itself exclusively to this type of weigher and discontinued the production of pointer scales. In the years that followed, the machines became ever more powerful and universally applicable. The continuous improvement is based in particular on the use of modern electronics. In order to focus on development in this area, W. L. Krämer spun off the „electrical department“ of ATOMA in 1978 and founded the Electroprocess GmbH, company for measurement and control technology.

Its tasks are the development and production of load cells and control systems. The scale controllers developed in this company in conjunction with the measuring sensors, the so-called load cells, which also originate from this company, make it possible to statistically process the recorded weight values. From 1984, the Weighing machines with strain gauge load cells equipped. ATOMA concludes an exclusive agency agreement with the German tubular bag machine manufacturer. The demand for the automatic weighing machines is so great that production can barely keep up.

Development of a distribution network

The situation changed abruptly a few years later when this company was sold to a large German group. The latter already owns another manufacturer of automatic weighing machines in its group of companies and therefore cancels the contract with ATOMA. ATOMA is now confronted with the need to find a new manufacturer with the help of sales representatives in Germany and Europe. Own distribution network to build up. As the company was already quite successful on the French market, it decided to develop this market itself and founded its first sales and service subsidiary, ATOMA societé pour les techniques de l'emballage s.a.r.l., in 1978. This was followed in 1986 by the founding of ATOMA Benelux B. V., based in Eindhoven, the Netherlands. In 1991, the decision was made to establish MULTIPOND Ltd. in the London area as a third subsidiary.

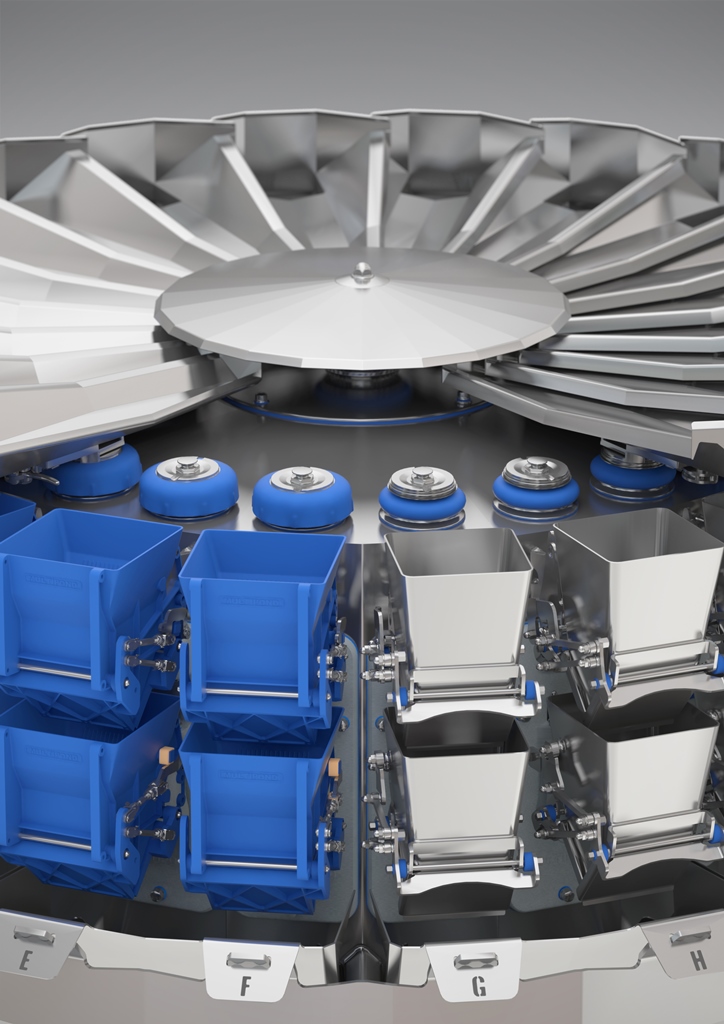

Development of the subset-combination principle

The further development of scale construction is decisively characterised by electronics. Electronic components are becoming ever smaller, more powerful and cheaper. This is fundamentally changing the filling scales. The greatest possible accuracy of a portion on so-called linear scales depends on the unit weight of a product. It is within a tolerance of +/- 1 piece. The way is now clear to pursue and technically realise an approach that has been occupying technicians for some time. Microprocessors use the individual weights of a large number of weighing systems to determine the combination that corresponds exactly to the target weight of the total portion or comes closest to it. 1984 the company is constructing its first building according to the combination weighing machines working on the principle of partial quantities, which can be found under the MULTIPOND brand to the market. Founded in Waldkraiburg in 1987, the MULTIPOND Wägetechnik GmbH takes over sales and service for this new type of scale.

Red containers become a recognisable symbol

W. L. Krämer is the first manufacturer to decide to manufacture the containers of the scales from a high-quality, food-approved, antistatic, anti-adhesive, ice and grease-repellent plastic. The „red container“ of a MULTIPOND scale will soon become an unmistakable recognisable feature on the world market. One of the company's strengths has always been the Weighing difficult products. In close co-operation with the customer, we develop automatic weighing machines for unusual applications. The application technology department takes on the difficult tasks and always focuses on optimising the customer's production process.

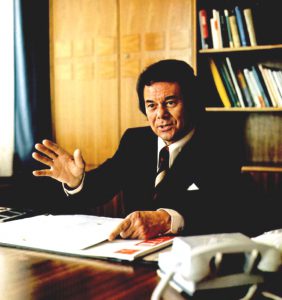

Handover to the second generation

In 1997, W. L. Krämer can look back on over 50 years of successful management and hands over the reins to his successors, his two sons Robert and Wilhelm Krämer and Margret Stemick. Wilhelm Krämer took over sales and marketing, Margret Stemick took care of all commercial matters and Robert Krämer was responsible for operations management. In 1998, the decision was made to establish a subsidiary in America. Located within MULTIPOND GmbH, it is opened under the name MULTIPOND America Inc. in Green Bay, USA.

The Group's developments are going well, and in 2002 the new „DW“ weigh feeder for powdery to granular products is launched on the market. This is followed over the next three years by a whole Series of market launches. The „Topping Unit“ was introduced in 2003. The scale is particularly suitable for smaller batch sizes and is a good solution for frequent product and location changes. 2004 saw the market launch of the „LW“ series of combination scales. A new multihead weigher for weighing products that cannot be conveyed automatically due to their characteristics was launched on the market in 2005 in the form of the MULTIPOND „SAL“ series.

interpack is still the largest and most important trade fair in the packaging industry. It is regarded as an indispensable event for all decision-makers. In 2014, MULTIPOND presented itself thanks to the new J-generation as a pioneer in the industry. The investment in the main site in Waldkraiburg supports the company's success. A Three million euro investment will be used for a new technical centre, a cold storage room and the new central warehouse. The cold room and technical centre now create optimum conditions for customer trials. The cold room in particular now enables trials with frozen products under real conditions. The central warehouse optimises the Group's entire production process. In 2015, Margret Stemick hands over her part of the management, the administration and personnel division, to Karl Hans Bauer.

The MULTIPOND brand

With more than 70 years of experience, MULTIPOND has made a name for itself as a market-leading, innovative Manufacturer of multihead weighers made. Today, the MULTIPOND brand stands for quality, reliability and innovative, customised solutions worldwide. Its success is based on the high quality and technical standard of its weighing systems.

The company continues to consciously focus on a high level of vertical integration and production exclusively in Germany. This guarantees a consistently high standard of quality and allows us to respond flexibly to even the most difficult customer requirements. More than 4,500 successfully installed weighing systems sold speak for themselves.

Corporate maxim

The topic Customer orientation has become the Group's corporate maxim. A team of now more than 250 employees worldwide do everything in their power to always offer customers from the food and non-food sectors the optimum, customised solution, precisely tailored to their requirements. In production, MULTIPOND deliberately focusses on the Core competenceswhich Weighing and dosing technology, and the Process steps before and after weighing, The weighing system is responsible for the weighing process, i.e. feeding the product to the weigher and reliably transferring the weighed portion to the packaging machine. MULTIPOND is the only manufacturer of multihead weighers in the world that designs and produces these components „in-house“ and integrates them into the systems. Control and synchronisation interfaces are part of the basic software.

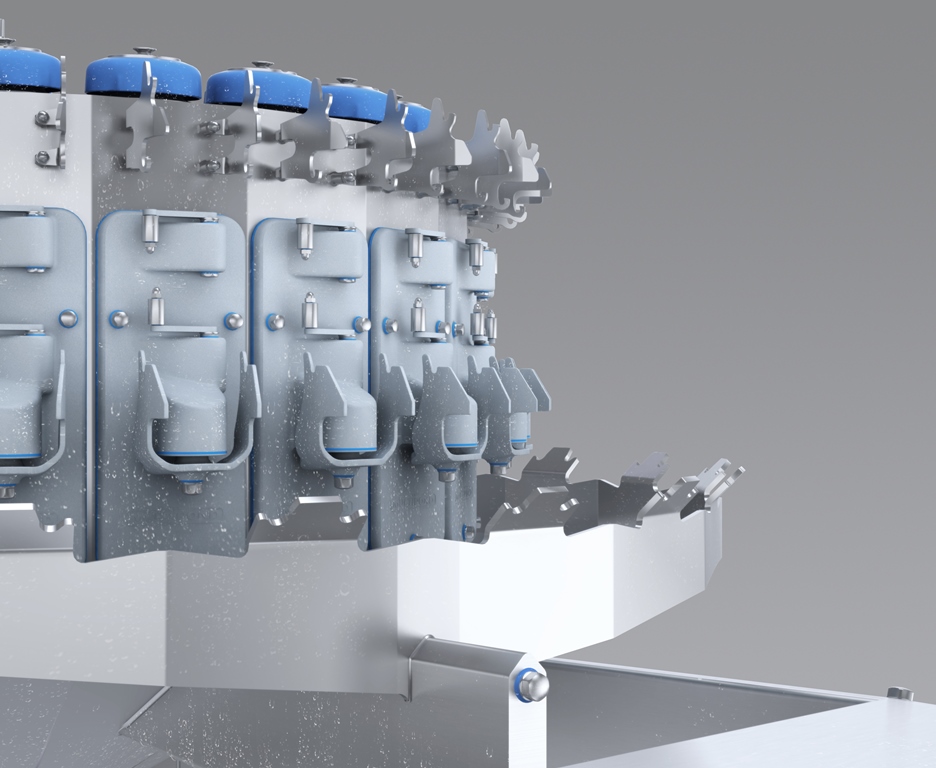

Highest hygiene standards

MULTIPOND has completely redefined the topic of hygienic design with the introduction of the new generation of scales, setting a benchmark in the industry. According to industry experts from the USA, the company is a big step ahead of the industry with its new hygienic design. In order to consistently achieve a high standard of hygiene the Group is a member of the EHEDG. MULTIPOND has even gone one step further in terms of hygiene: The new J-generation is equipped with protection class IP69 as standard. In contrast to the competition, this protection class has been achieved without generating excess pressure in the machine.