ABB has automated what used to be done by hand for Jack Link's. The popular BiFi snack is automatically sorted and packaged using ABB delta robots, because after the confectionery industry, the meat industry is also working on automating production and packaging processes.

Until the turn of the millennium, many sorting processes in the meat industry were still carried out by hand. At BiFi manufacturer Jack Link's, employees were still manually sorting BiFi sausages on the line and placing them in the trays of the thermoforming machine in the early 2000s. The commissioning of the robotic sorting system in 2006 marked a foray of automation into new hygienic application areas represent.

How can BiFi sausages be automatically gripped and packaged as efficiently as possible? With this in mind, the then young company Robomotion was commissioned to design a suitable robot cell for the BiFi packaging system. At the time, the Stuttgart-based start-up with its three founders Steffen Mayer, Jan Binder and Dr Andreas Wolf was working on the integration of robots into series machines in the meat industry. It soon became clear that the technological principle, Grasp products quickly according to specific criteria using image processing, control technology, sensors and sophisticated gripper technology, was also of great interest for applications in the food industry.

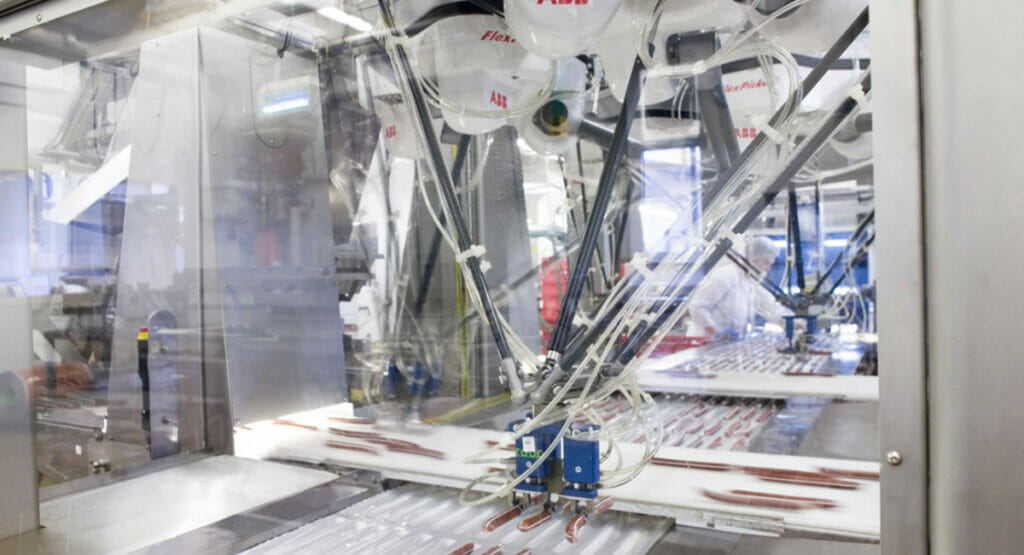

As part of a co-operation ABB The company provided the startup with an IRB 340 FlexPicker delta robot. Due to their parallel kinematics, robots of this type are ideal for Suitable for handling tasks with high demands on speed and precision, for example, from a conveyor belt into a packaging machine. With the ABB robots as the centrepiece, Robomotion was tasked with developing and validating a robot system in its role as system integrator. Preliminary tests in the laboratory demonstrated that the ABB robots were capable of reliably feeding up to 150 BiFi sausages per minute into the thermoforming packaging process using mechanical grippers. ABB in turn assumed responsibility for servicing and maintaining the robot system during operation.

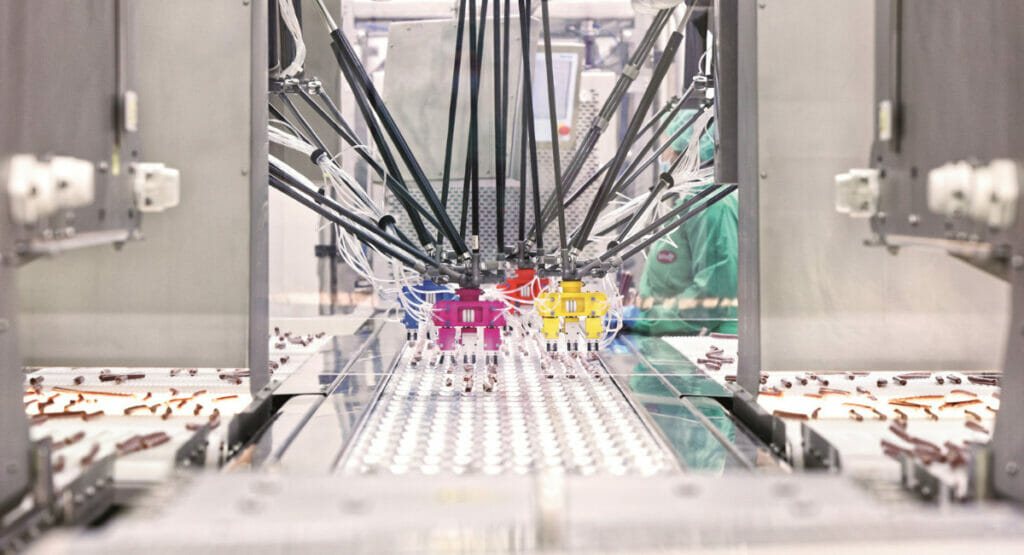

Following a successful test phase, a total of four IRB 340 FlexPickers from ABB were installed in the first system. With the help of the connected feeding technology, the BiFi sausages are Robomotion vibration sections and distributed by four FlexPickers for sealing into the moulds in the prepared thermoforming film. Cameras installed along the conveyor line not only check the quality, but also analyse the position of the sausages.

Based on this information, the robots know exactly how to „pick“ the sausages thanks to ABB's PickMaster software for camera-assisted picking and packaging applications. Behind this is an image processing system that is able to recognise the sausages as such despite their different curvatures. For the sake of efficiency, the robot has to pick up not just one, but three sausages at a time. To ensure this precision and process reliability at the same time, the opening and closing of the grippers is timed to the millisecond.

„The automation solutions that we have been able to implement in collaboration with Robomotion and ABB over the past few years have fully met our expectations. The systems are reliable, low-maintenance and offer high availability. This also has a positive effect on the total cost of ownership.“

Alfred Gehr, Operations Manager at Jack Link's

The successful commissioning of the first robot system in BiFi production was just the beginning of an ongoing research and optimisation process. For example, as part of the BiFi project, the team worked with Fraunhofer IPA to develop a 3D-printed grippers for the robots to save weight and make the handling process even more efficient. design. Since 2009, the triple grippers used in production have come from the 3D printer.

Over the years, the range of meat snacks at Jack Link's has grown noticeably. The various BiFi types differ not only in their composition, but also in some cases in their size and shape. This is no problem for the flexible ABB robots, equipped with the PickMaster software. adaptations to the programme and the image processing software, they are able to adapt to product variants. Only the packaging machine itself requires a mould change.

Once the sausages have been sorted and thermoformed, the outer packaging is then sealed and the sausages are placed in cartons. To do this, a FlexPicker robot from ABB groups the sealed sausages on a conveyor belt into a formation, which a second robot equipped with suitable grippers picks up and distributes in groups onto cartons. As the boxes for the different BiFi products vary in size, the robots need to be flexible when sorting them. With a The system can be adapted to a new product by quickly changing the gripper and adapting the robot software. The secondary packaging system is also the product of the proven co-operation between ABB Robotics and Robomotion.

Source: ABB

More news on automation

Dortmund becomes the meeting place for packaging and intralogistics

White paper | How to make packaging machines more dynamic through lightweight construction

Powerful automation for mills

LogiMAT 2026 showcases current trends and future-proof solutions