In a joint recycling project, Mars, Sabic and Landbell are working on a circular alternative for the flexible packaging of the KIND snack bar. The mono-material application consists of certified and circular PP.

Sabic has teamed up with Mars and Landbell in an advanced recycling project to minimise the Loop for flexible packaging using certified, circular polypropylene (PP) from the company's TRUCIRCLE portfolio. In a joint initiative with major market players, Mars will introduce biaxially orientated polypropylene (BOPP) film based on Sabic's certified circular PP from the recycling of used plastics in the packaging of its primary healthy snack brand KIND.

„We are very excited about this ground-breaking circular project, which demonstrates the feasibility and speed of realising circular plastic innovations when leading players from across the value chain work closely together. Used flexible packaging has a high raw material value for new materials, and our TRUCIRCLE polymers and services are an important element in unlocking this huge potential.“

Lada Kurelec, General Manager PP, PET, PS, PVC, PU & Elastomers Businesses for Petrochemicals at Sabic

The new mono-material packaging solution continues the partners' efforts to support a circular economy by incorporating advanced recycled content into healthy snack bar packaging.

„At Mars, we want to contribute to a circular economy in which packaging material does not become waste, but is recycled, reused or composted. To achieve this, we need new solutions and infrastructures that change the recycling landscape and complement mechanical recycling. Today is another important step in our journey towards sustainable packaging and in our collaboration with partners like Sabic who are creating new opportunities to provide consumers with packaging designed for the circular economy.“

Barry Parkin, Chief Procurement & Sustainability Officer at Mars

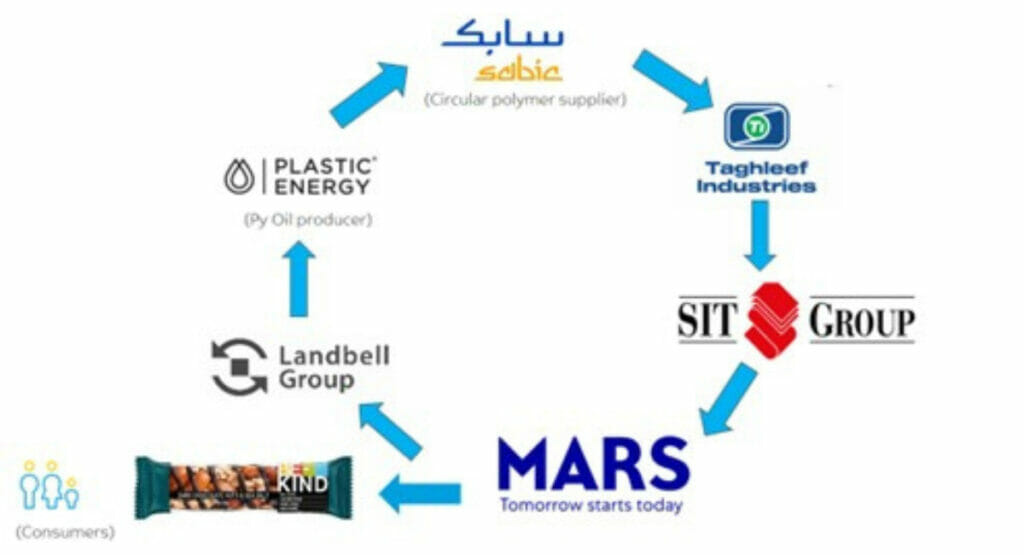

The cycle begins with the Collection of mixed used plastics coordinated by Landbell Group. Landbell works with Hündgen Entsorgung to sort the mixed waste plastics and delivers the mixed material to Plastic Energy, a global leader in advanced recycling technology, where it is processed in a is converted into pyrolysis oil using a patented thermal-anaerobic conversion process. The pyrolysis oil serves as an alternative raw material in Sabic's production process for new PP polymer approved for food contact, which is pelletised and supplied to Taghleef Industries, a leading global supplier of biaxially oriented PP film (BOPP).

„Mixed used plastics from flexible consumer packaging are difficult to sort and mechanically recycle. However, as this circular project demonstrates, we can provide effective, advanced recycling solutions that enable plastics and packaging manufacturers as well as OEMs and brand owners to recover and benefit from the value of mixed used plastics while reducing the consumption of fossil resources and improving their carbon footprint.“

Uwe Echteler, Chief Operating Officer of Landbell Group

SIT Group, a major supplier of high quality printed flexible plastic packaging to the European consumer market, is using Taghleef's BOPP film together with Sabic's certified round polymer to produce printed BOPP roll-fed packaging for KIND brand snack bars and sell it to Mars. The joint initiative will support the partners in realising their ambitious Support goals to reduce the amount of plastics from fossil sources and accelerate the transition to a more circular plastics economy.

The new flexible BOPP packaging structure made from food-safe recycled PP is another important milestone on the road to Mono-material applications that facilitate end-of-life recycling in existing collection and processing streams without compromising on quality or ease of processing. Mars has already integrated certified round PP polymers from the TRUCIRCLE portfolio into the primary packaging of some of its popular wet pet food brands SHEBA. Following successful trials, the certified round PP food polymer will now also be introduced into the packaging of KIND snack bars.

Source: Sabic

More news on plastics and composites

adapa completes refinancing

Klöckner Pentaplast significantly reduces debt

EFSA has finalised data call

Vilsa bottle combines the advantages of glass and PET